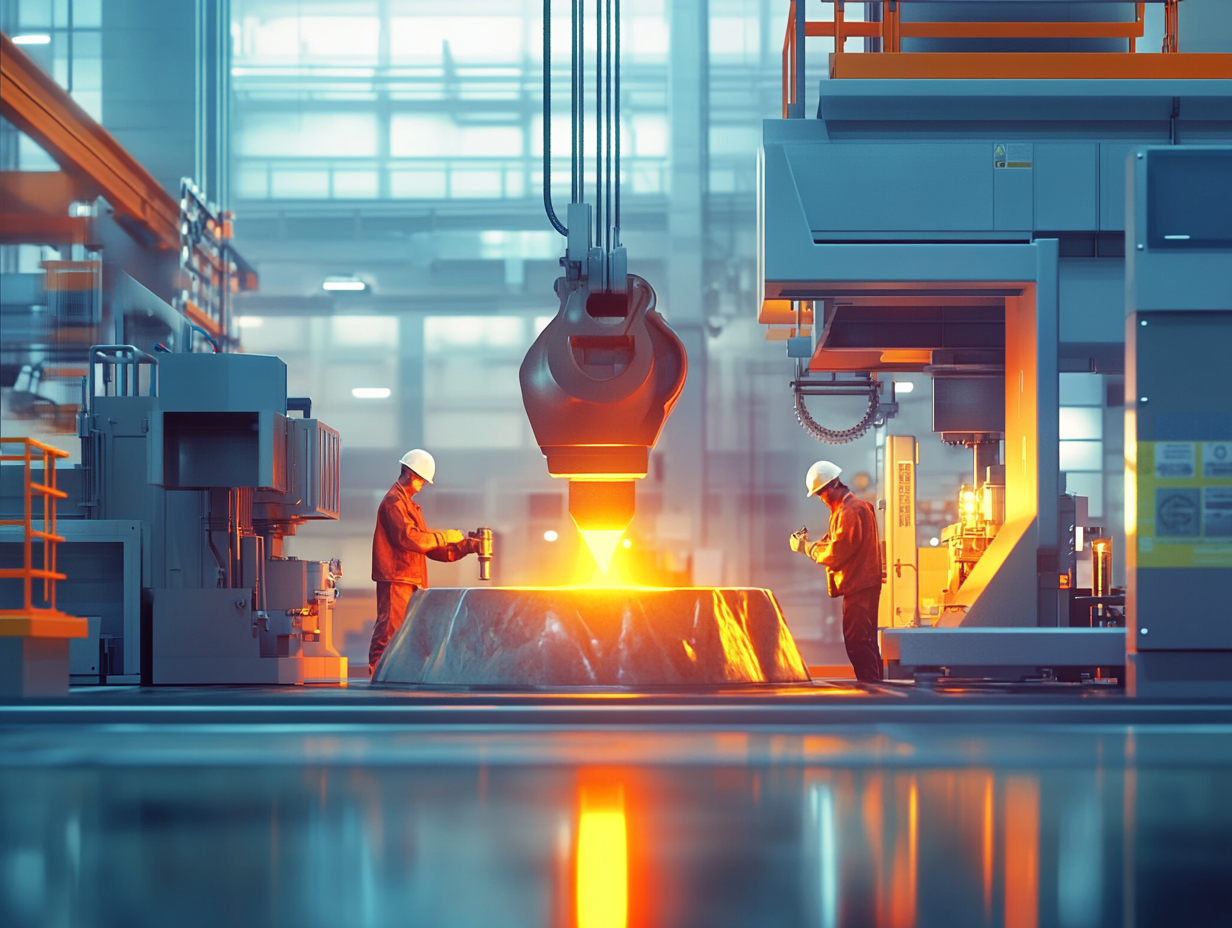

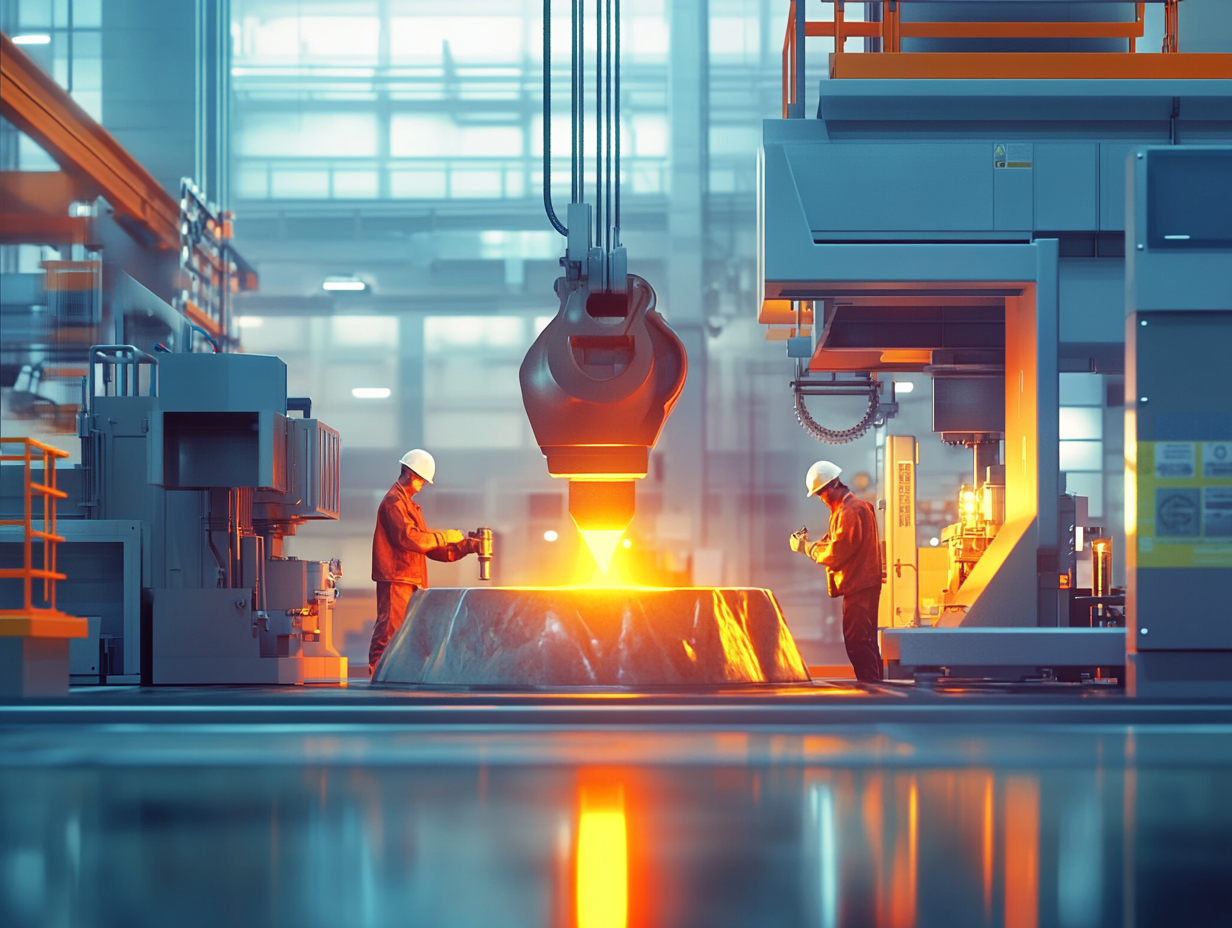

Casting is an essential process in industrial manufacturing, supporting diverse industries such as automotive, construction, heavy machinery, and precision equipment. Producing flawless and cost-effective cast parts depends heavily on the design decisions made at the initial stages. Design not only impacts the durability of the material but also influences production costs and efficiency. Here are the key principles for successful casting design:

1. Adherence to Tolerances

Tolerances define the final dimensions and functionality of cast parts. Adhering to international standards like ISO and DIN ensures minimal deviations during production, resulting in higher precision and cost savings. Tolerance groups such as DTA and DTB are widely used by foundries to maintain production consistency. Accurate tolerances streamline assembly processes and improve customer satisfaction.

2. Material Selection and Wall Thickness

The choice of material directly impacts the strength and manufacturability of cast parts. Proper wall thickness ensures uniform material flow, reduces shrinkage defects, and prevents voids or bubbles. Utilizing techniques like the HEUVER method helps optimize material distribution, minimizing defects and enhancing overall quality.

3. Shaping Techniques and Production Efficiency

Shaping techniques are critical to efficient casting production. Overly complex designs may increase costs and lead to manufacturing errors. Simplified designs with optimized core usage and draft angles reduce production challenges and accelerate lead times. Proper separation of molds and patterns also lowers tooling and production expenses.

4. Cost Optimization and Collaboration

Collaborating with casting experts during the design phase is a strategic way to reduce costs. Key factors like model costs, material usage, and tolerances drive overall expenses. While manual molding is suitable for small batches, automated molding techniques provide cost-effective solutions for large-scale production.

Conclusion

Casting design is more than an engineering task; it’s a strategic approach to improving production efficiency and reducing costs. By focusing on tolerances, material selection, shaping techniques, and cost optimization, businesses can achieve flawless and cost-effective cast parts. These principles not only enhance quality but also provide a sustainable competitive edge in the market.