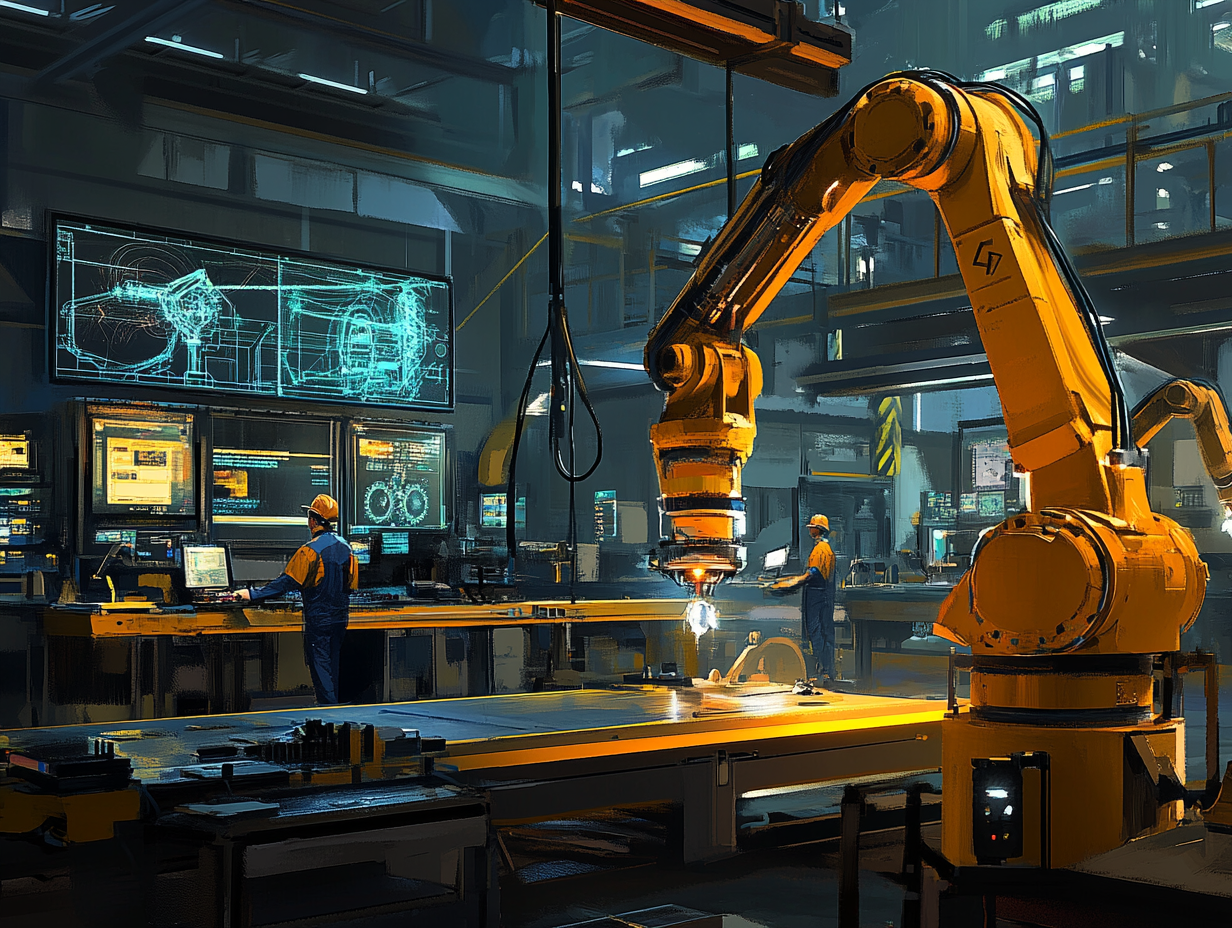

Bending is a crucial step in metal forming, but post-bending welding plays an equally vital role in enhancing the durability and functionality of the final product. Proper welding applications ensure the structural integrity of materials while meeting safety and quality standards. This blog explores post-bending welding techniques, key considerations, and applications in various industries.

1. Importance of Post-Bending Welding

During bending, the inner and outer surfaces of metal experience different stress levels. Welding balances these stresses, ensuring long-lasting performance.

- Stress Reduction:

- Reinforcing bent areas with welding minimizes the risk of cracking.

- Structural Integrity:

- Proper welding enhances material strength and prepares it for extended use.

2. Welding Types and Their Applications

a) MIG/MAG Welding:

- Advantages:

- Fast and efficient for thin metals.

- Applications:

- Automotive chassis parts and sheet metals.

b) TIG Welding:

- Advantages:

- Provides aesthetic and precise welds.

- Ideal for stainless steel and aluminum.

- Applications:

- Aerospace components with intricate details.

c) Arc Welding:

- Advantages:

- Suitable for thick materials and cost-effective.

- Applications:

- Construction beams and pipelines.

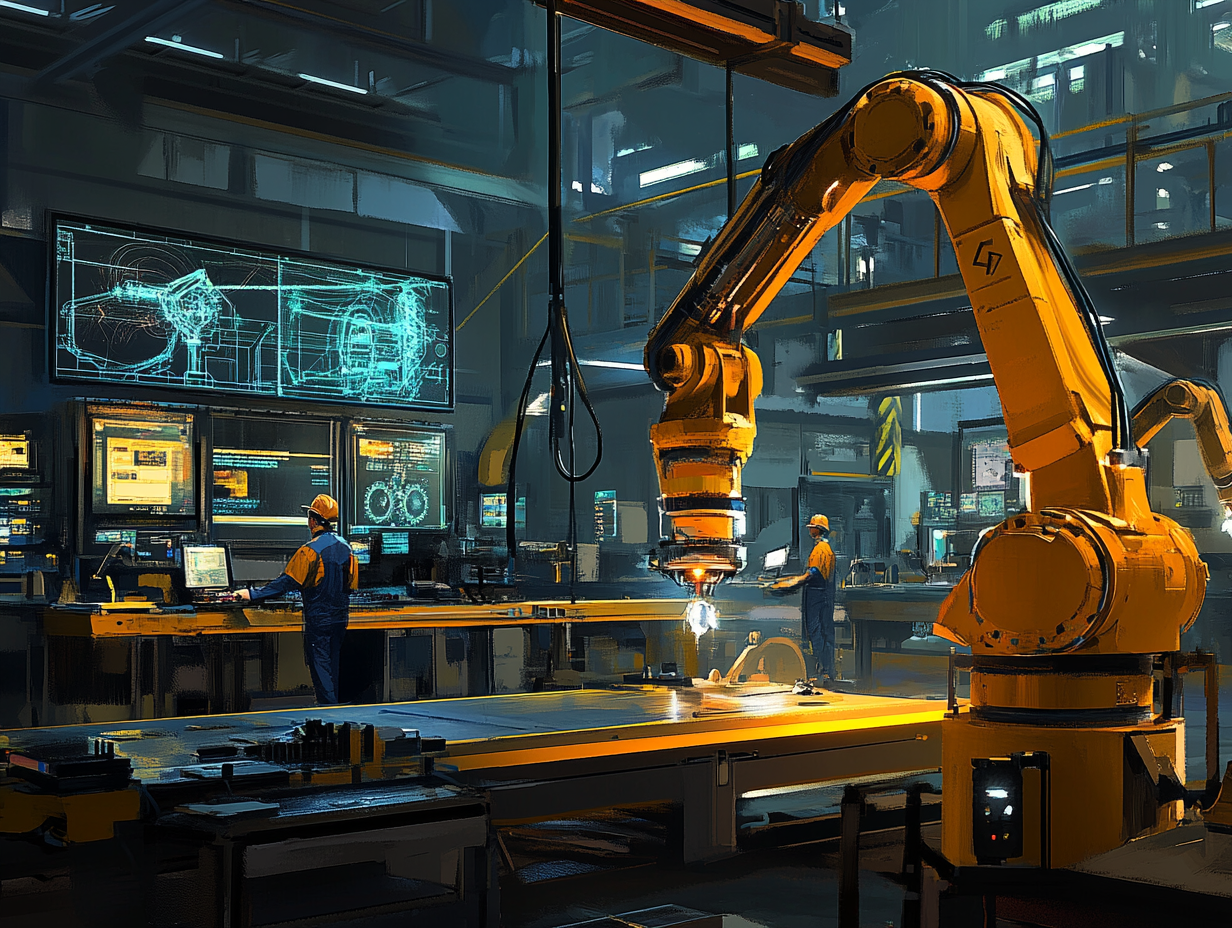

3. Key Considerations in Post-Bending Welding

- Surface Preparation:

- Ensure welding surfaces are clean and smooth.

- Remove oil, rust, and contaminants to maintain weld quality.

- Choosing the Right Method:

- Select the welding technique based on material type and thickness.

- Using Appropriate Equipment:

- Opt for low-amperage machines for precise welds on thin materials.

4. Post-Welding Inspection and Testing

a) Visual Inspection:

- Check weld seams for smoothness and aesthetic quality.

b) Non-Destructive Testing:

- Ultrasonic Testing: Detects internal cracks.

- Magnetic Particle Testing: Identifies surface defects.

c) Mechanical Testing:

- Tensile Test: Measures the strength of the weld.

- Impact Test: Evaluates resistance to sudden loads.

5. Applications Across Industries

Automotive:

- Welding chassis components.

- Ensuring exhaust system seals.

Aerospace:

- Joining lightweight and durable fuselage components.

- High-temperature engine parts.

Construction:

- Reinforcing steel structures.

- Securing pipelines for safe transport.

- Post-bending welding enhances the durability and safety of metal components. With proper methods and careful execution, manufacturers can reduce costs while achieving high-quality standards.