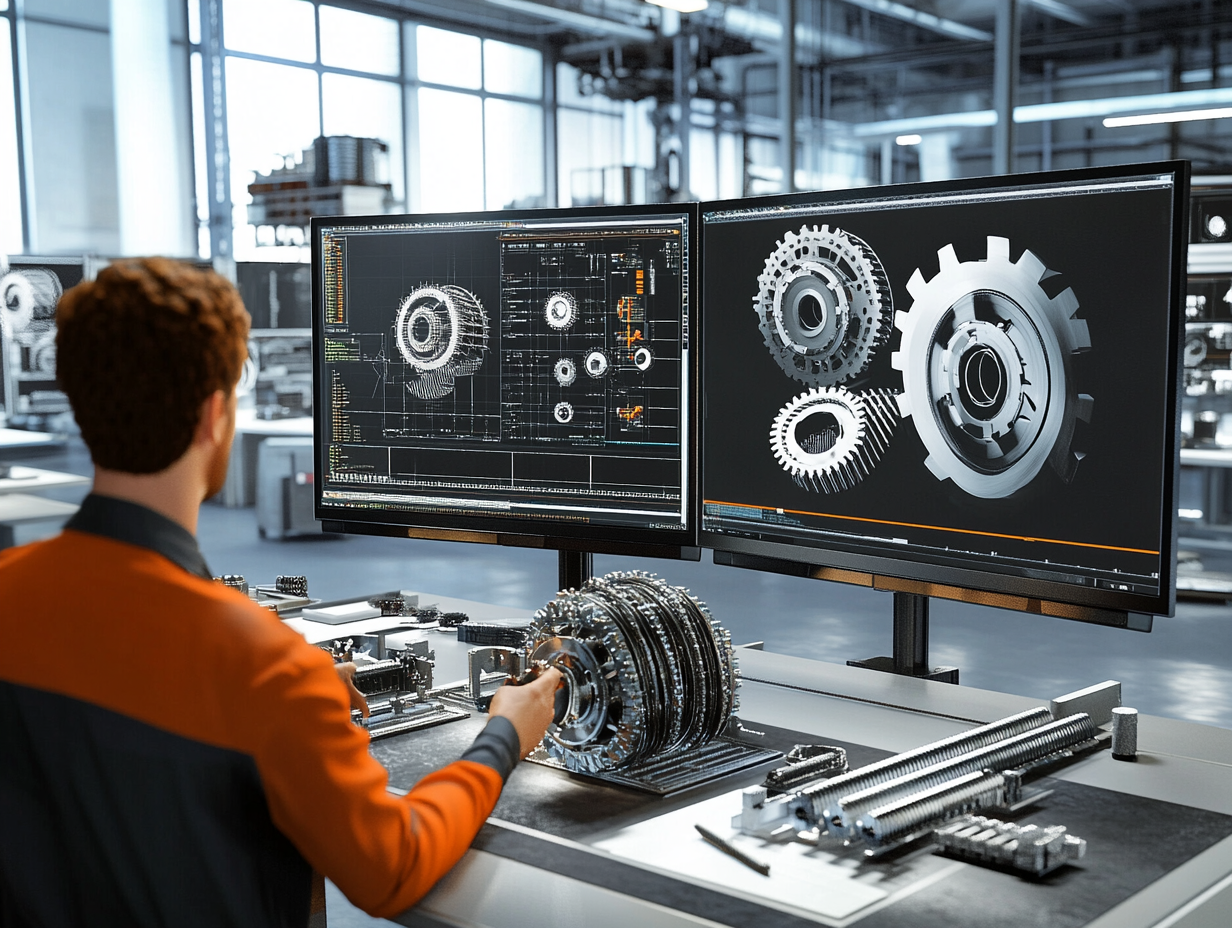

Before delving into gear design, it is essential to understand the fundamental terminology. This article covers the most important concepts in gear terminology.

Basic Gear Terms

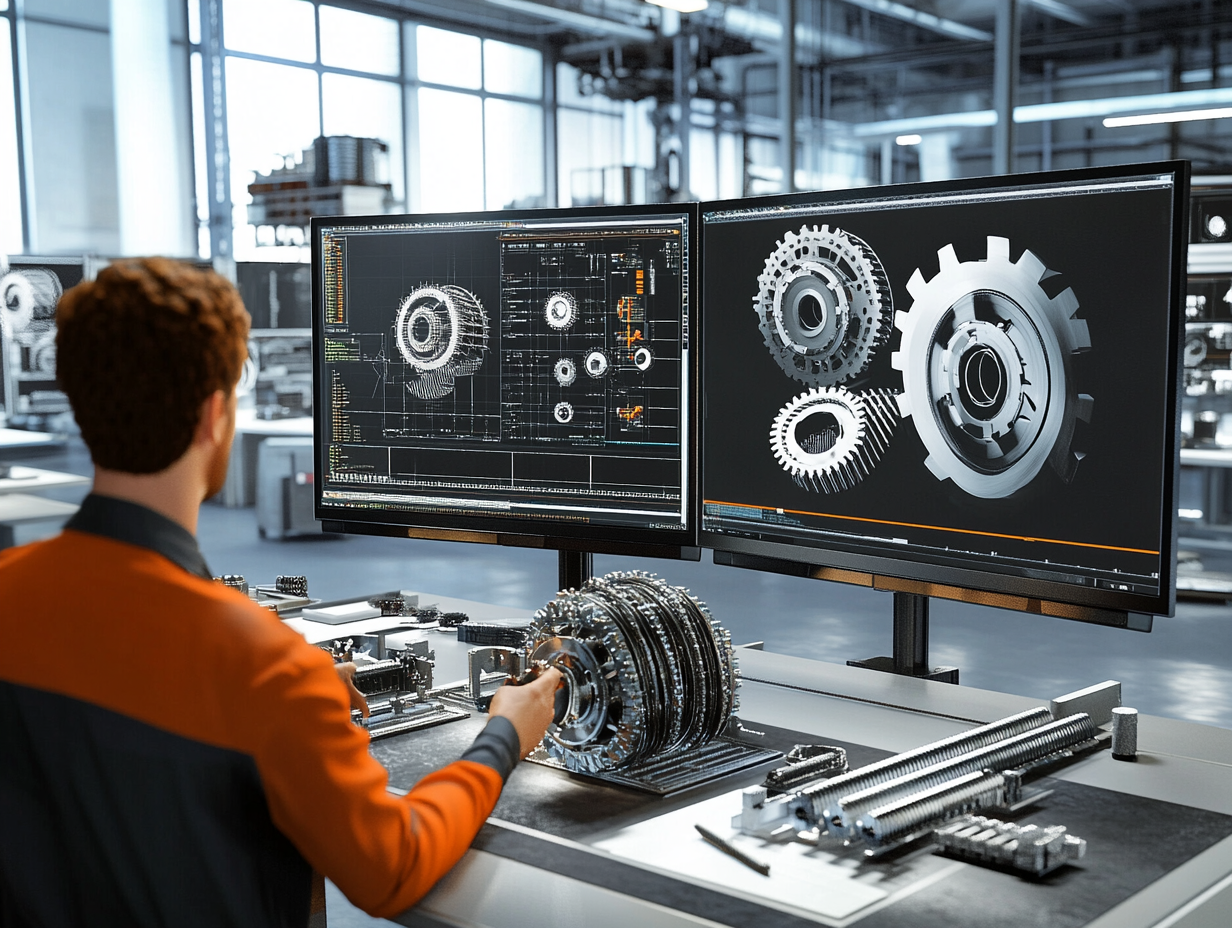

- Main Gear: In a gear pair, the gear with more teeth.

- Pinion Gear: In a gear pair, the gear with fewer teeth.

- Pitch Circle Diameter (PCD): The circle where the gear pair transmits force and motion.

- Number of Teeth on Main Gear (ZG): The number of teeth must be an integer.

- Number of Teeth on Pinion Gear (ZP): If the number of teeth falls below a certain level, interference increases.

- Center Distance (C): The distance between the centers of the main gear and the pinion gear.

Gear Profile and Dimension Terms

- Base Circle: The circle from which the involute curve starts.

- Involute: The curve that forms the gear profile.

- Root Circle: The circle that passes through the gear root.

- Addendum (a): The radial distance from the pitch circle to the top of the tooth.

- Dedendum (d): The radial distance from the pitch circle to the bottom of the tooth.

- Tooth Height: The sum of addendum and dedendum.

- Working Height: The sum of the addendums of two meshing gears.

- Clearance (c): The gap between the top of one gear tooth and the root of the mating gear tooth.

- Backlash: The space left between meshing teeth when one gear is engaged.

Module and Gear Standardization

- Module (M): The pitch circle diameter divided by the number of teeth, measured in mm.

- Diametral Pitch (DP): A value used in AGMA standards instead of module.

- Pressure Angle (Φ): The angle between the line of action and the tangent to the pitch circle.

- Understanding gear terminology correctly ensures precision in design and manufacturing while guaranteeing optimal gear performance. These terms are essential for anyone working with gears.