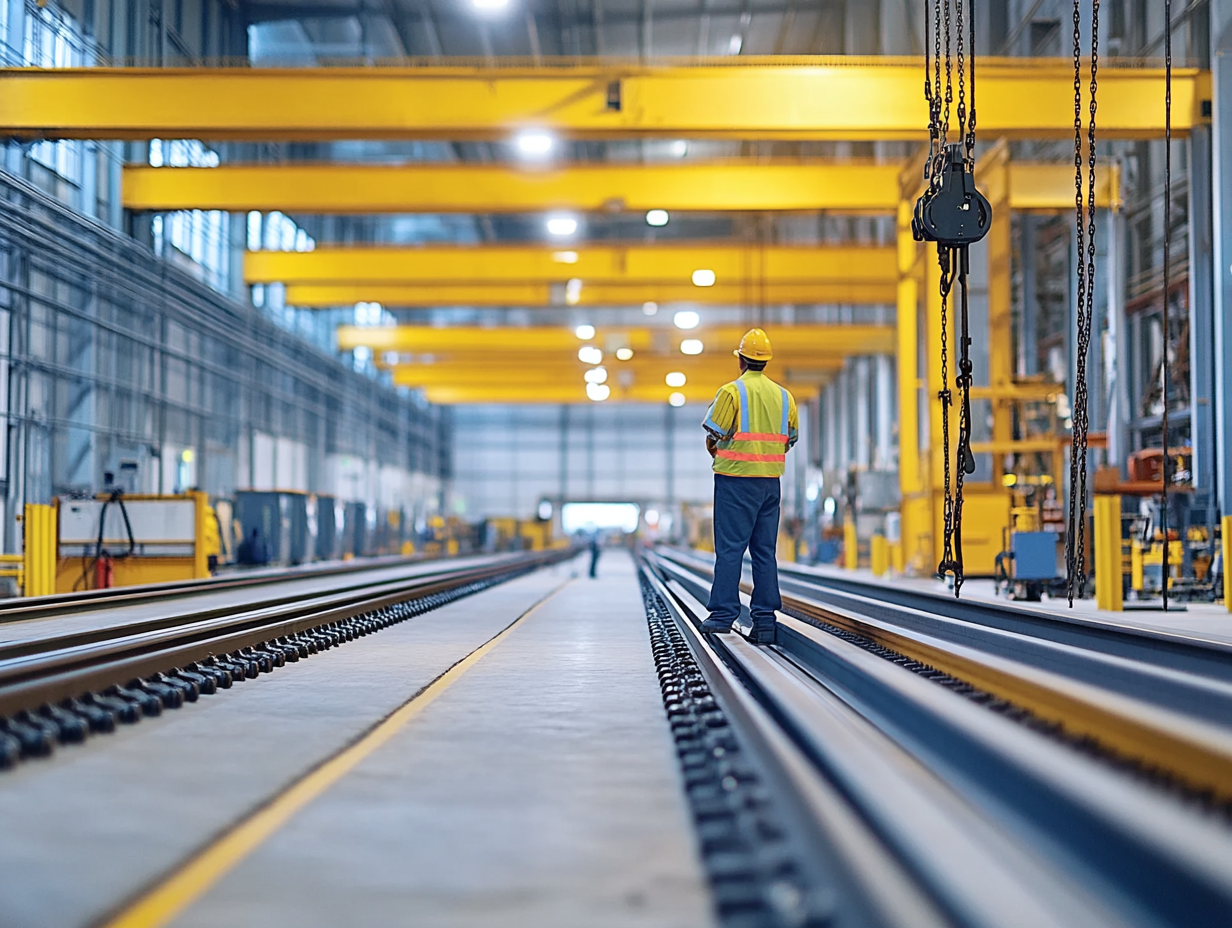

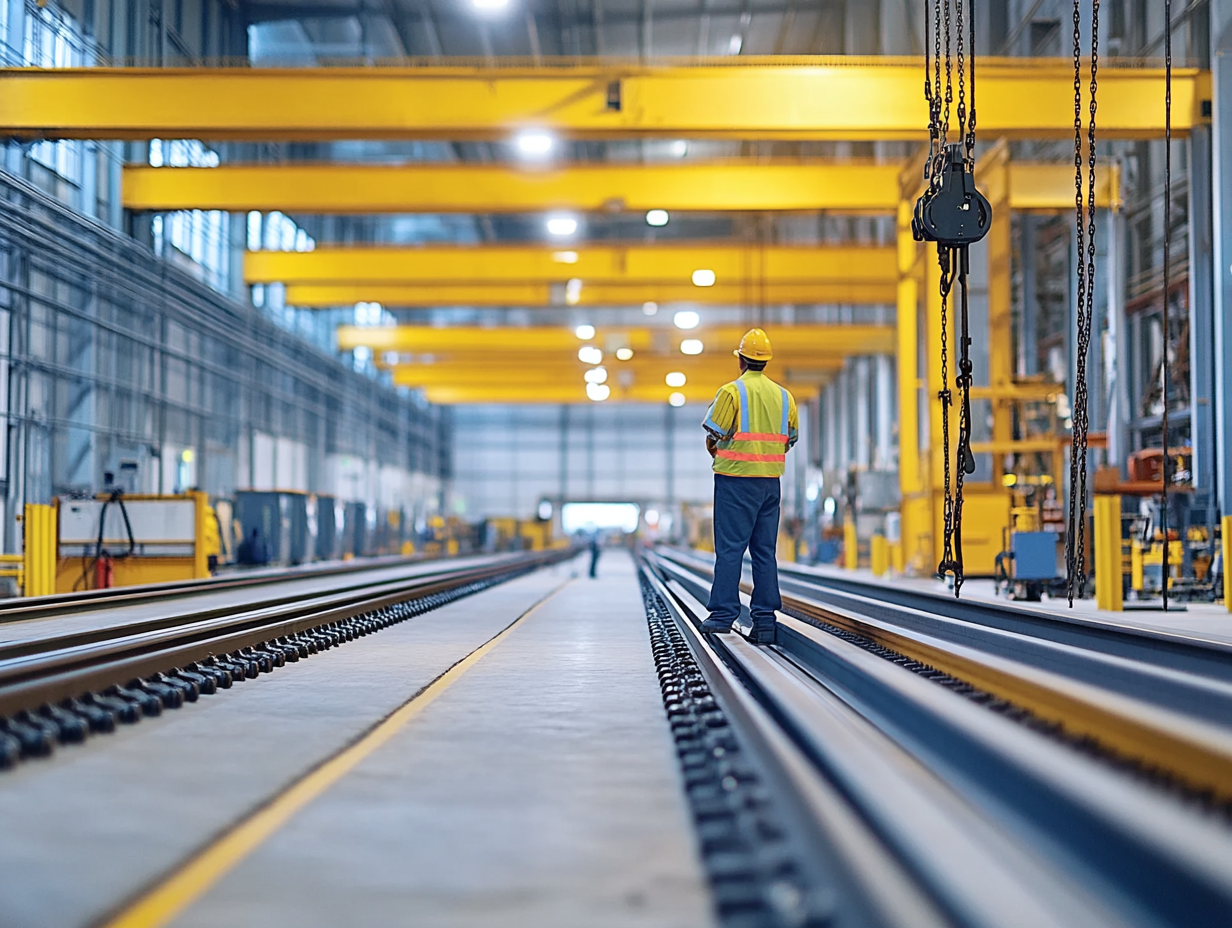

Flat bar crane rails, also known as laminated rails, are a widely used alternative to traditional crane rail profiles. These rails are particularly favored in light to medium-duty applications, offering flexibility and cost-effectiveness. However, they also come with specific limitations that must be considered when designing crane track systems. This blog explores the pros and cons of flat bar crane rails and their ideal applications.

1. Advantages of Flat Bar Crane Rails

✔ Cost-Effective Solution

- Flat bar rails are generally less expensive than standard DIN 536 rails.

- Requires simpler installation, reducing labor and material costs.

✔ Lightweight and Flexible

- Offers easier handling and installation compared to heavier rail profiles.

- Can be custom-cut and adapted to various track layouts.

✔ Smooth Surface for Reduced Wear

- Provides a consistent rolling surface for crane wheels, minimizing localized wear.

- Reduces friction and energy consumption, improving operational efficiency.

✔ Low Profile Design

- Requires less structural height, making it ideal for low-clearance environments.

- Easier to integrate into existing industrial floors and surfaces.

2. Disadvantages of Flat Bar Crane Rails

✖ Limited Load Capacity

- Not suitable for heavy-duty applications like steel mills or container ports.

- May deform under high-impact or repetitive heavy loads.

✖ Less Resistance to Lateral Forces

- More susceptible to side-load impacts, leading to misalignment over time.

- Requires additional bracing or fastening to prevent shifting.

✖ Increased Maintenance Requirements

- Needs more frequent inspections due to higher wear rates in heavy-use areas.

- Welding or bolting techniques must be carefully maintained to prevent loosening.

✖ Shorter Lifespan Compared to Heavy-Duty Rails

- Subject to faster surface wear, especially in high-traffic environments.

- May require replacement sooner than hardened steel rail profiles.

3. Best Applications for Flat Bar Crane Rails

✔ Workshops and Small-Scale Production Facilities

✔ Light-to-Medium Load Warehouses

✔ Indoor Material Handling Systems

✔ Automated Guided Vehicle (AGV) Tracks

✔ Temporary or Low-Cost Crane Installations

4. Comparison: Flat Bar vs. Traditional Crane Rails

| Factor | Flat Bar Crane Rail | Traditional Crane Rail (DIN 536) |

|---|---|---|

| Cost | Lower | Higher |

| Load Capacity | Low to Medium | High |

| Flexibility | High | Limited |

| Lifespan | Shorter | Longer |

| Maintenance Needs | Frequent | Less Frequent |

5. Key Considerations When Choosing Flat Bar Rails

✔ Evaluate Load Requirements → Ensure they meet the system’s operational needs.

✔ Consider Environmental Factors → Avoid use in high-impact or outdoor conditions.

✔ Plan for Maintenance → Regular inspections and realignments may be required.

✔ Use Proper Fastening Techniques → Secure installation prevents misalignment.

- Flat bar crane rails are an excellent choice for light-duty applications, offering cost savings, flexibility, and easy installation. However, for heavy loads and long-term durability, traditional crane rails remain the preferred option. Choosing the right rail depends on operational needs, budget, and expected wear conditions.