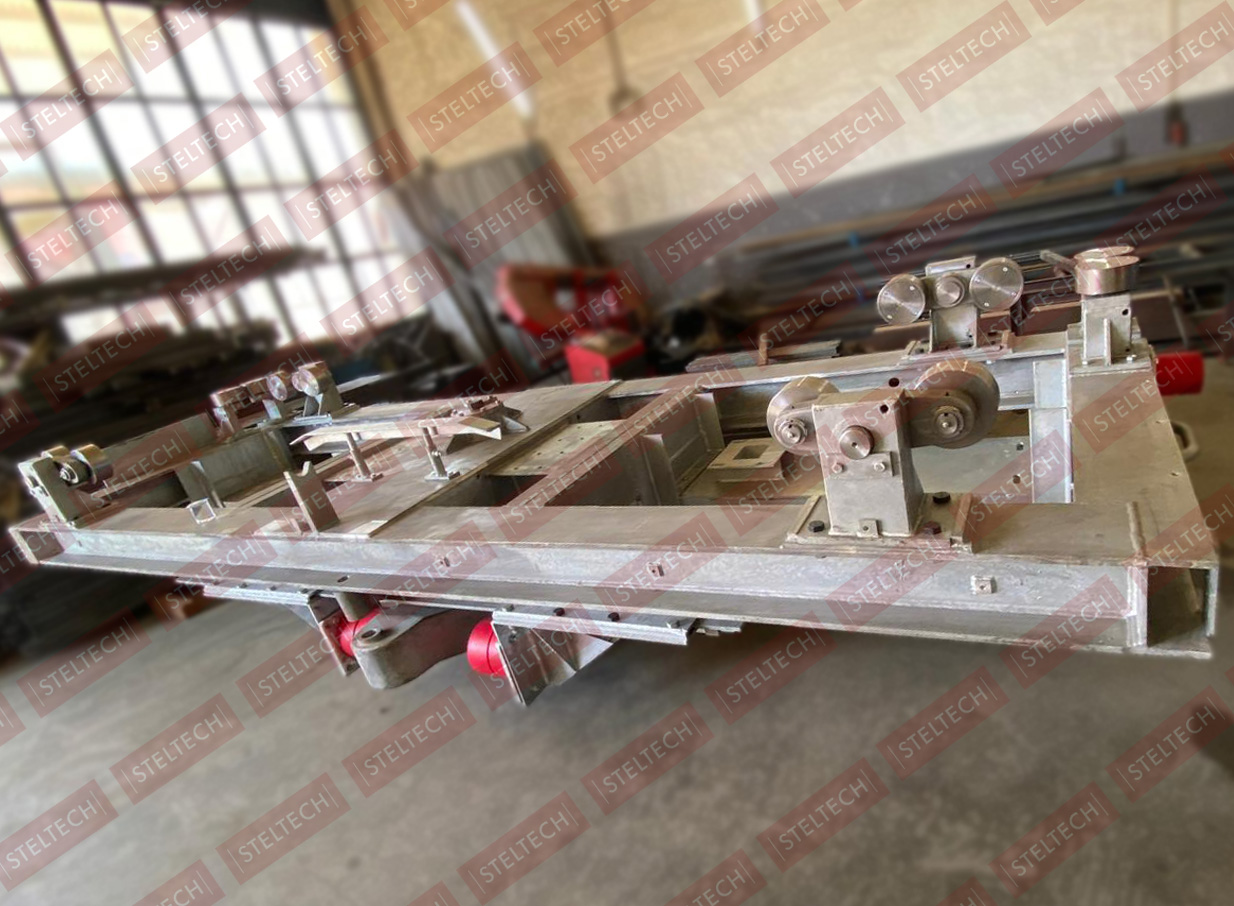

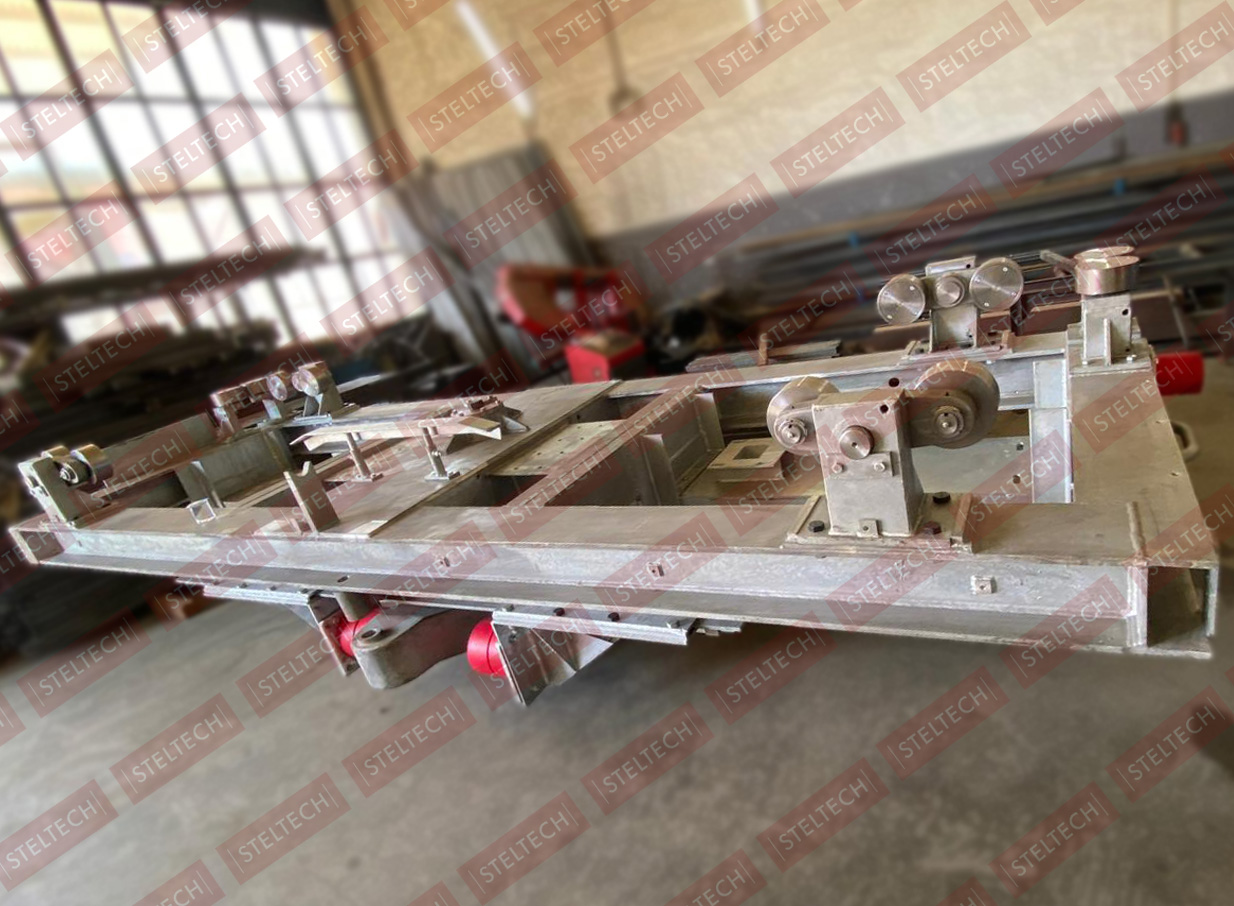

In the heart of every coke production facility lies a series of mechanical systems that ensure efficiency, safety, and continuity. One such critical component is the coal discharge plough, responsible for diverting, guiding, and discharging coal from conveyor systems during the coking process. This specialized equipment, manufactured with high precision by Steltech, plays a vital role in keeping coke plant operations smooth and uninterrupted.

What Is a Coal Discharge Plough?

A coal discharge plough is a mechanical unit installed along a coal conveyor line, designed to push or divert coal off the conveyor at specific unloading points. Unlike traditional chutes or gates, the plough engages with the bulk material dynamically, typically without stopping the belt.

Steltech’s plough is specifically designed for high-temperature, dusty, and high-vibration environments found in coke plants, where abrasion resistance, stability, and low-maintenance operation are essential.

Application in Coke Plants

In coke production, coal is continuously transported from storage to the coke oven charging system. During this process, different coal types may need to be discharged at specific points for blending, storage, or feeding.

Steltech’s discharge plough is used to:

-

Divert coal onto different bunkers or bins

-

Clean the belt by removing residual coal before it returns

-

Allow controlled unloading at critical points

-

Prevent spillage and ensure environmental safety

The plough must engage quickly, apply uniform force, and retract smoothly — often under automated PLC control.

Engineering Features of Steltech’s Coal Plough

Steltech’s design integrates:

-

High-strength galvanized steel chassis for corrosion resistance

-

Precision-machined pulley and roller assemblies for smooth lateral motion

-

Industrial-grade mechanical linkages to withstand repetitive loading

-

Heavy-duty locking mechanisms to keep the plough in exact position

-

Modular mounting for easy field service and replacement

Thanks to its robust welded frame and premium materials, this unit delivers long operational life even under harsh industrial stress conditions.

Advantages for Coke Plants

-

Minimized Downtime: Quick activation and deactivation reduce operational interruptions.

-

Improved Safety: Prevents belt overflows and structural coal buildup.

-

Lower Maintenance: Heavy-duty rollers and housing reduce wear.

-

High Adaptability: Suitable for integration with most conveyor systems.

-

Precision Discharge: Ensures consistent distribution of material to target bunkers.

Coal discharge ploughs may seem like a small part of the overall coke production process, but their reliability and precision directly impact plant efficiency. Steltech’s engineering expertise has delivered a rugged, refined solution tailored for coke plant environments — where uptime, safety, and performance are non-negotiable.