In the real world, components rarely experience a single, clean load. Instead, they’re often subjected to multiple forces acting in different directions. When it comes to shafts, axles, beams, and structural frames in mining and heavy industry, this results in combined bending moments, which must be carefully calculated for safe and efficient design.

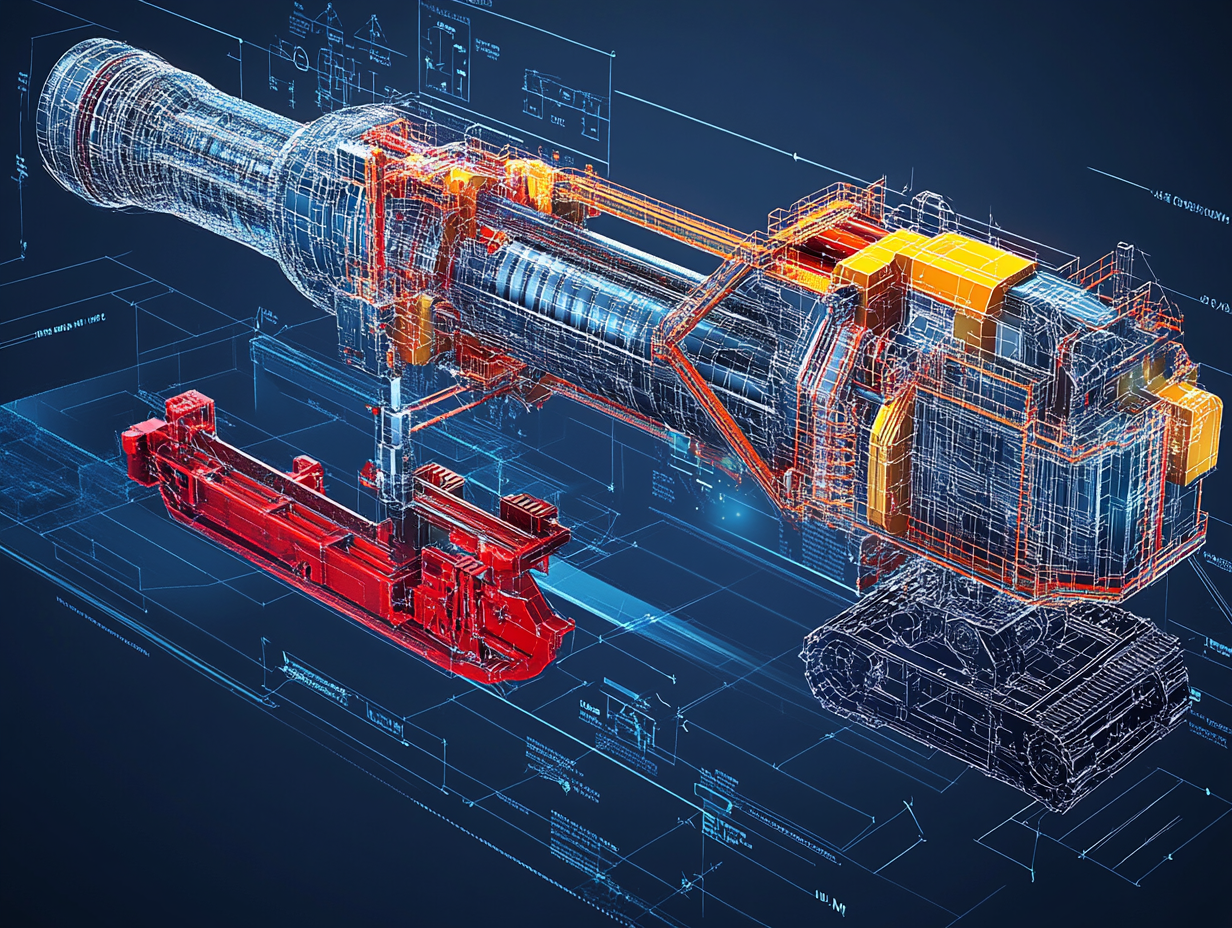

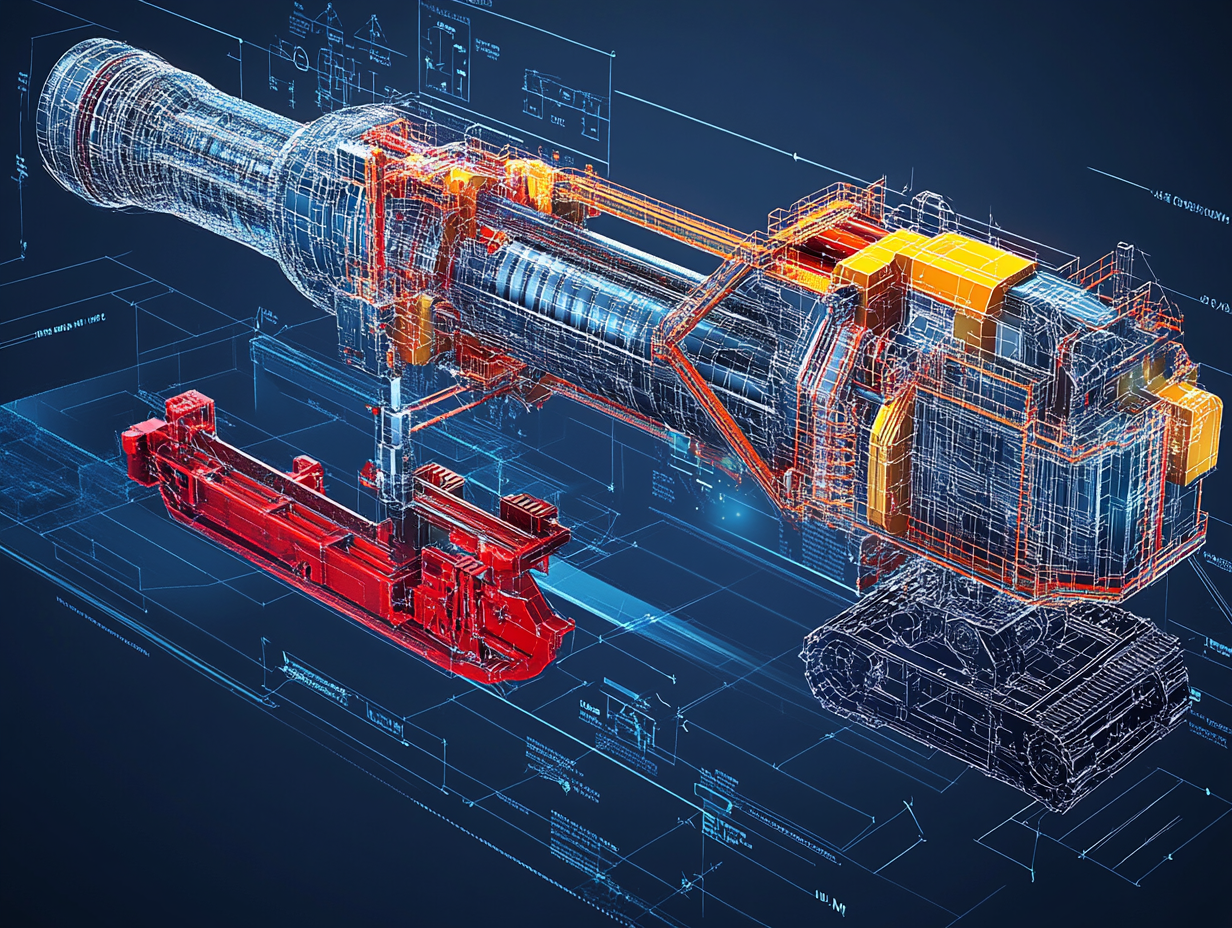

Understanding combined or biaxial bending is essential when designing parts that encounter off-center loads, uneven torque paths, or multi-axial stress — typical in cranes, drilling rigs, and support structures.

1. What Is a Combined Bending Moment?

A combined bending moment occurs when a structural member is subjected to bending about two perpendicular axes simultaneously, such as:

-

Vertical bending (M<sub>y</sub>)

-

Horizontal bending (M<sub>x</sub>)

Instead of analyzing them separately, engineers use vector addition to find the resultant moment.

2. Formula for Resultant Bending Moment

Mr=Mx2+My2M_r = \sqrt{M_x^2 + M_y^2}

Where:

-

MxM_x = Bending moment about x-axis (horizontal plane)

-

MyM_y = Bending moment about y-axis (vertical plane)

-

MrM_r = Resultant bending moment

✅ This value is used in stress calculations to evaluate material safety under complex loads.

3. Application in Mining and Industrial Structures

🛠️ Common examples:

-

Portal crane legs resisting wind + vertical load

-

Overhead beam structures with eccentric loading

-

Boom arms of excavators bending under angle

-

Rotating shafts with pulley and gear loads in different planes

4. Calculating Bending Stress from Combined Moment

Once the resultant moment is found, the bending stress is:

σb=Mr⋅yIσ_b = \frac{M_r \cdot y}{I}

Where:

-

yy = Distance from neutral axis

-

II = Moment of inertia

The material must withstand this maximum stress without yielding, even under dynamic or fluctuating loads.

5. Combined Stress Check With Other Loads

In many mining components, combined bending happens alongside:

-

Shear (from direct forces)

-

Torsion (from motor drive)

-

Axial loads (e.g., compression from vertical structure)

Engineers should apply Von Mises or Maximum Principal Stress Theory to validate full safety:

σeq=σb2+3τ2σ_{eq} = \sqrt{σ_b^2 + 3τ^2}

6. Real-World Example: Crane Boom Arm

Let’s say a crane boom sees:

-

M<sub>x</sub> = 1200 Nm

-

M<sub>y</sub> = 1600 Nm

Then:

Mr=12002+16002=1440000+2560000≈2000 NmM_r = \sqrt{1200^2 + 1600^2} = \sqrt{1440000 + 2560000} ≈ 2000 \, \text{Nm}

This resultant moment is used in dimensioning the beam’s cross-section, choosing material, and determining allowable deflection.

7. FEM Tools and Safety Factors

For irregular or asymmetric cross-sections (like I-beams, H-columns, or lattice structures), use Finite Element Analysis (FEA) to:

-

Visualize multi-directional stress flow

-

Locate peak stress areas

-

Optimize geometry

Always apply appropriate safety factors (1.5–2.5) in mining applications, especially where fatigue or shock loads are present.

Combined bending moments aren’t just theoretical — they’re everywhere in industrial machinery. Ignoring them leads to unsafe designs, while applying them ensures reliable, efficient, and long-lasting equipment. In the complex world of mining engineering, mastering these calculations separates average systems from truly robust solutions.