In rotating machinery from mining conveyors to crushers and ventilation fans shafts must operate well below their critical speed to avoid destructive vibrations.

Critical speed is the rotational speed at which a shaft’s natural frequency matches its rotation frequency, leading to resonance.

This article explains how to calculate the critical speed of shafts, why it matters in mining equipment, and how to design for safe operation.

1. What Is Critical Speed?

Critical speed occurs when the centrifugal force from a rotating shaft equals the restoring force due to its stiffness.

At this speed:

-

Vibrations increase drastically

-

Noise rises

-

Shaft deflection becomes excessive

-

Components may fail from fatigue or bearing overload

2. Basic Critical Speed Formula

For a simply supported shaft with a central mass:

Nc=12πgδN_c = \frac{1}{2\pi} \sqrt{\frac{g}{\delta}}

Where:

-

NcN_c = Critical speed (rev/s)

-

gg = 9.81 m/s² (gravity)

-

δ\delta = Static deflection (m)

Static deflection δ\delta depends on shaft stiffness, which is influenced by material modulus EE, diameter, and span.

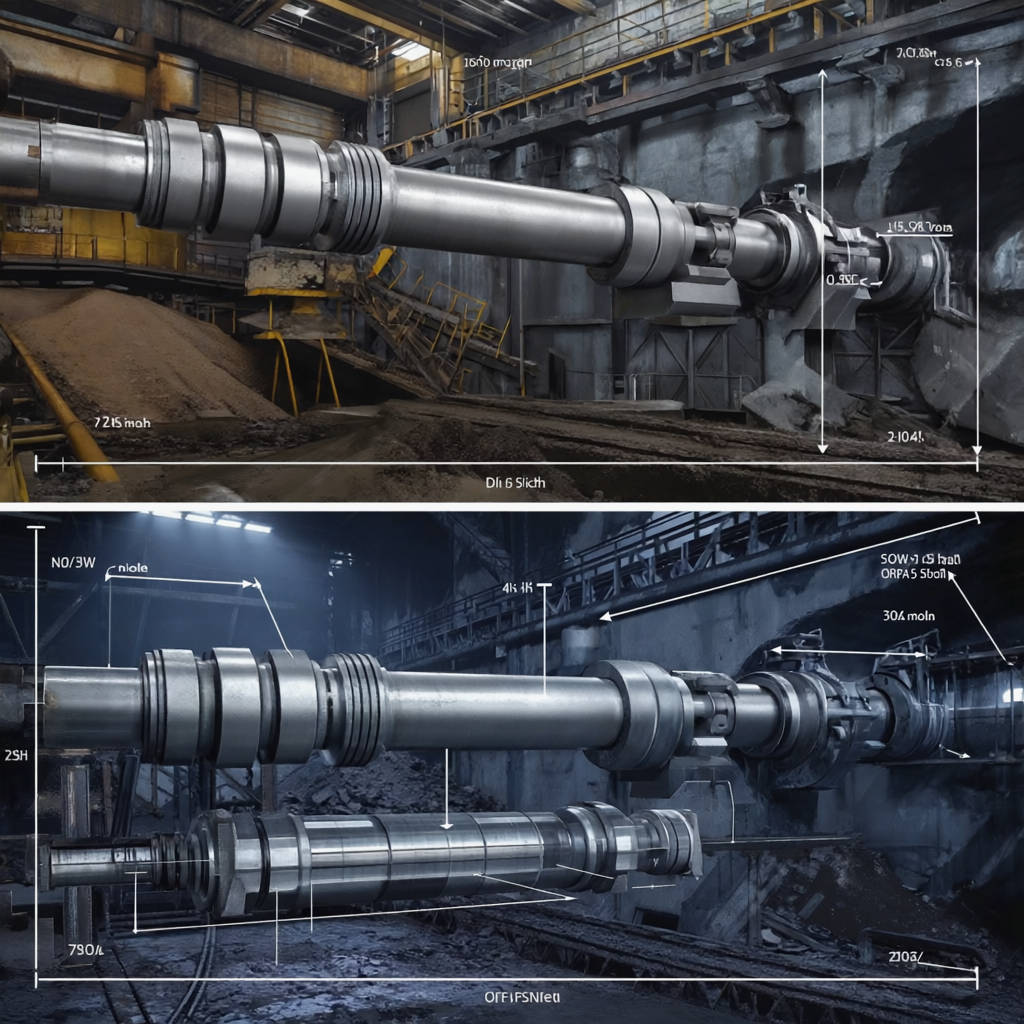

3. Example: Conveyor Drive Shaft

-

Span L=1.8 mL = 1.8 \, \text{m}

-

Diameter d=60 mmd = 60 \, \text{mm}

-

Load = Pulley + belt tension = 1200 N

-

Material: Steel (E=210 GPaE = 210 \, \text{GPa})

Calculate deflection under load, then determine NcN_c.

If operational speed is too close to NcN_c, redesign is needed — either by increasing shaft stiffness or changing load distribution.

4. Why It Matters in Mining Operations

Mining equipment often runs continuously at high speeds. A shaft operating near critical speed can cause:

-

Bearing failures

-

Misalignment of couplings

-

Reduced production due to downtime

✅ Keeping operating speed at 75% or less of NcN_c is a common engineering safety practice.

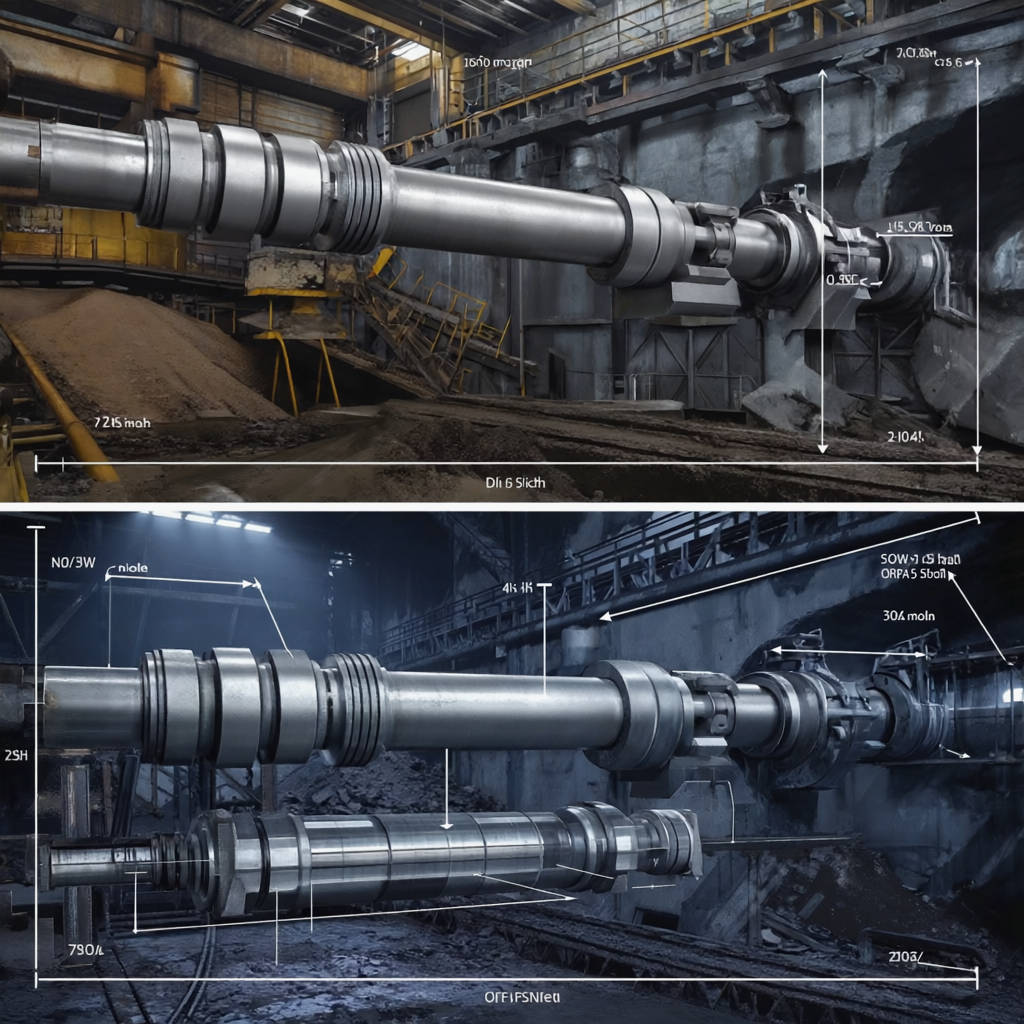

5. Design Strategies to Avoid Critical Speed Issues

✔️ Increase shaft diameter to raise stiffness

✔️ Reduce span length or add intermediate supports

✔️ Use lighter rotating parts to reduce load

✔️ Perform modal analysis for complex machinery

Understanding and calculating the critical speed of shafts is essential for safe, efficient mining operations. By staying well below resonance, engineers can protect equipment, avoid downtime, and extend component life.