Behind every powerful machine tool lies a simple question: how does the tool connect securely to the machine? This is where standards like DIN 10 and DIN 138 come in. They define the dimensions of shanks and sockets the “handshake” between tools and machines.

DIN 10: The Square End Connection

DIN 10 standardizes the square-shaped ends (Werkzeug-Vierkante) found on hand tools like taps.

-

These square ends ensure the tool fits perfectly into a handle or wrench.

-

They prevent slipping and make manual operations reliable.

💡 Example: The square end of a tap wrench — small, simple, but critical for accuracy.

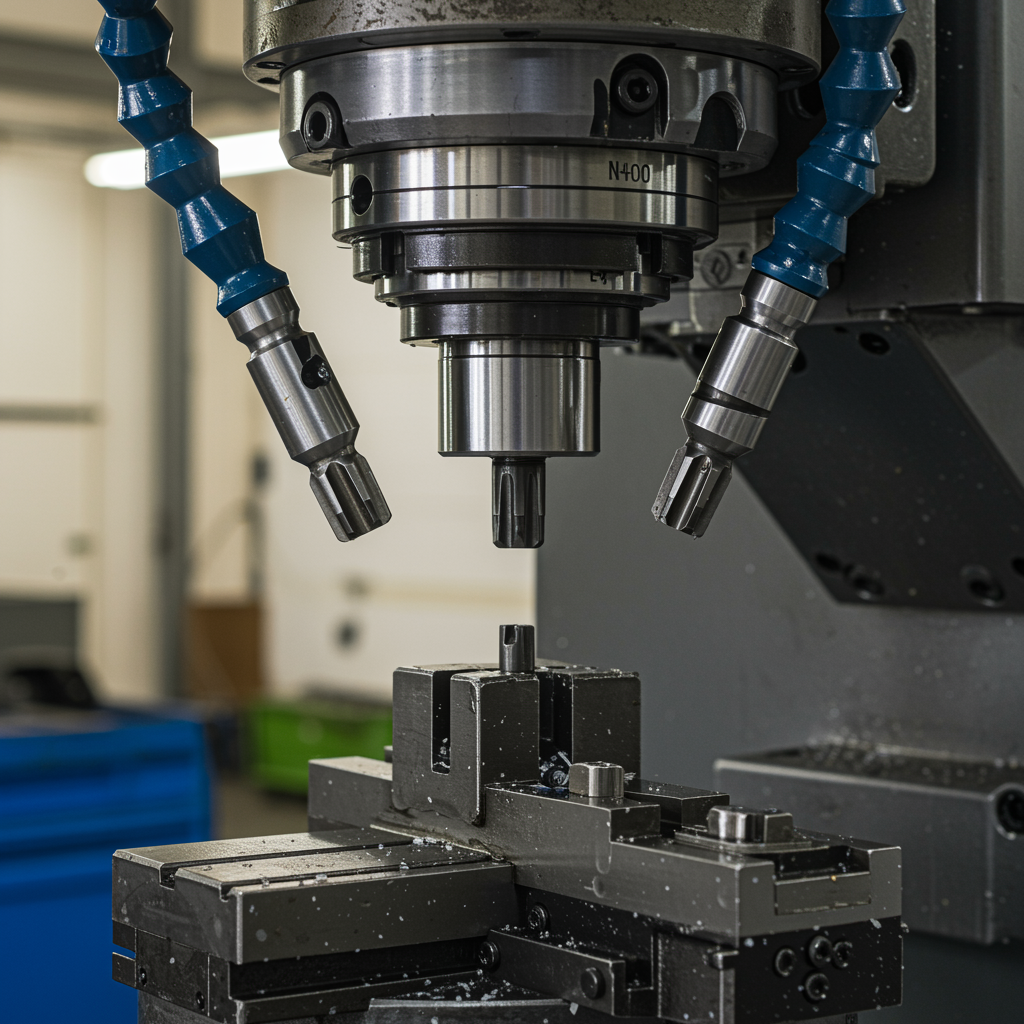

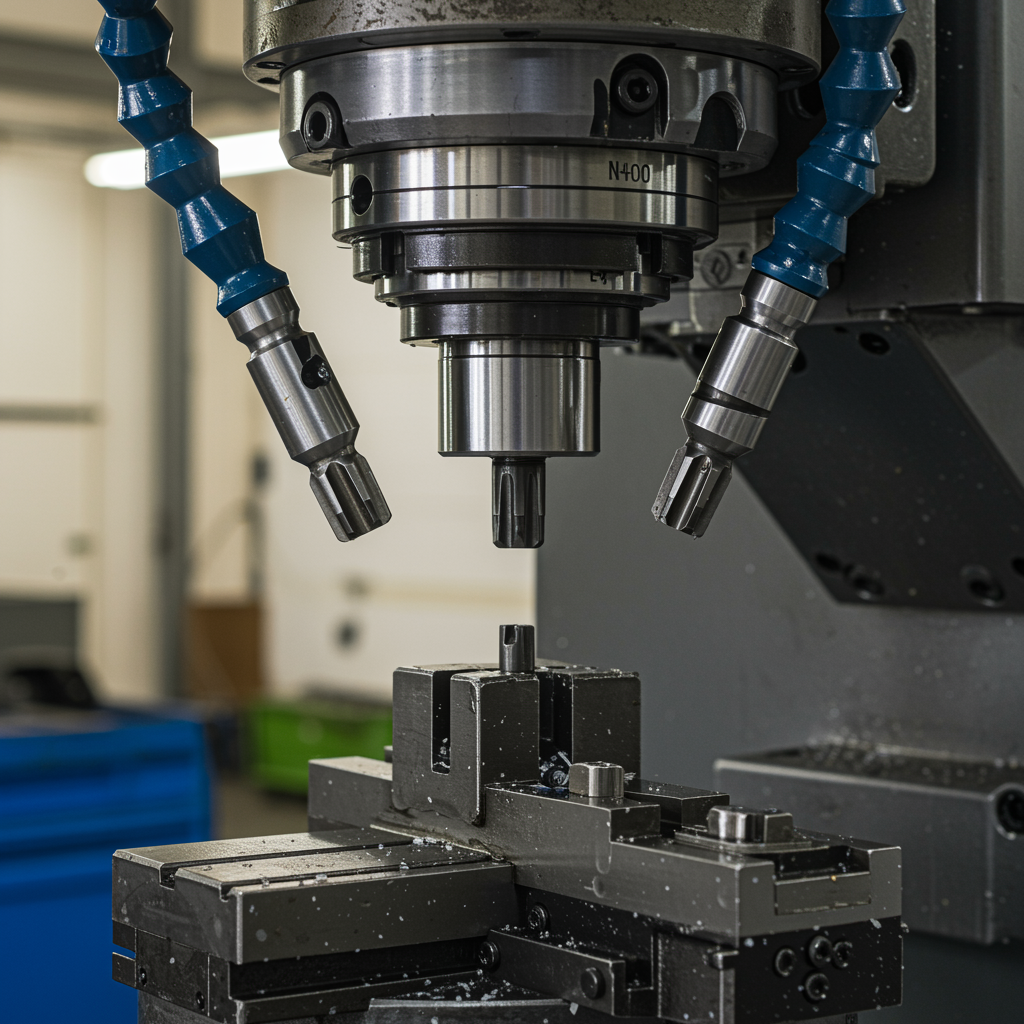

DIN 138: Cylindrical Shanks with Keys

For larger, more powerful tools, DIN 138 defines how cylindrical shanks mount onto a machine’s spindle. A key and keyway prevent the tool from slipping under high torque.

💡 Example: In a milling machine or drill press, the key ensures the tool and spindle rotate together as one solid unit — no room for error.

A Simple Analogy: The Socket Wrench Set

Think of a socket wrench: every socket fits on the same handle because the square drive is standardized. DIN 10 does the same for taps.

For DIN 138, imagine a car wheel bolted to its axle. The bolts ensure the wheel and axle move together without slipping, just like a key and keyway.

Why This Matters in Metalworking

✔️ Prevents tool slippage under load

✔️ Ensures compatibility across manufacturers

✔️ Reduces downtime by making tool changes fast and reliable

In mining and heavy industry, where downtime is costly, these connections guarantee both efficiency and safety.

Shanks and sockets may seem like small details, but they are the foundation of secure tool holding. Thanks to DIN 10 and DIN 138, machinists can trust that tools will connect smoothly and withstand the toughest jobs.