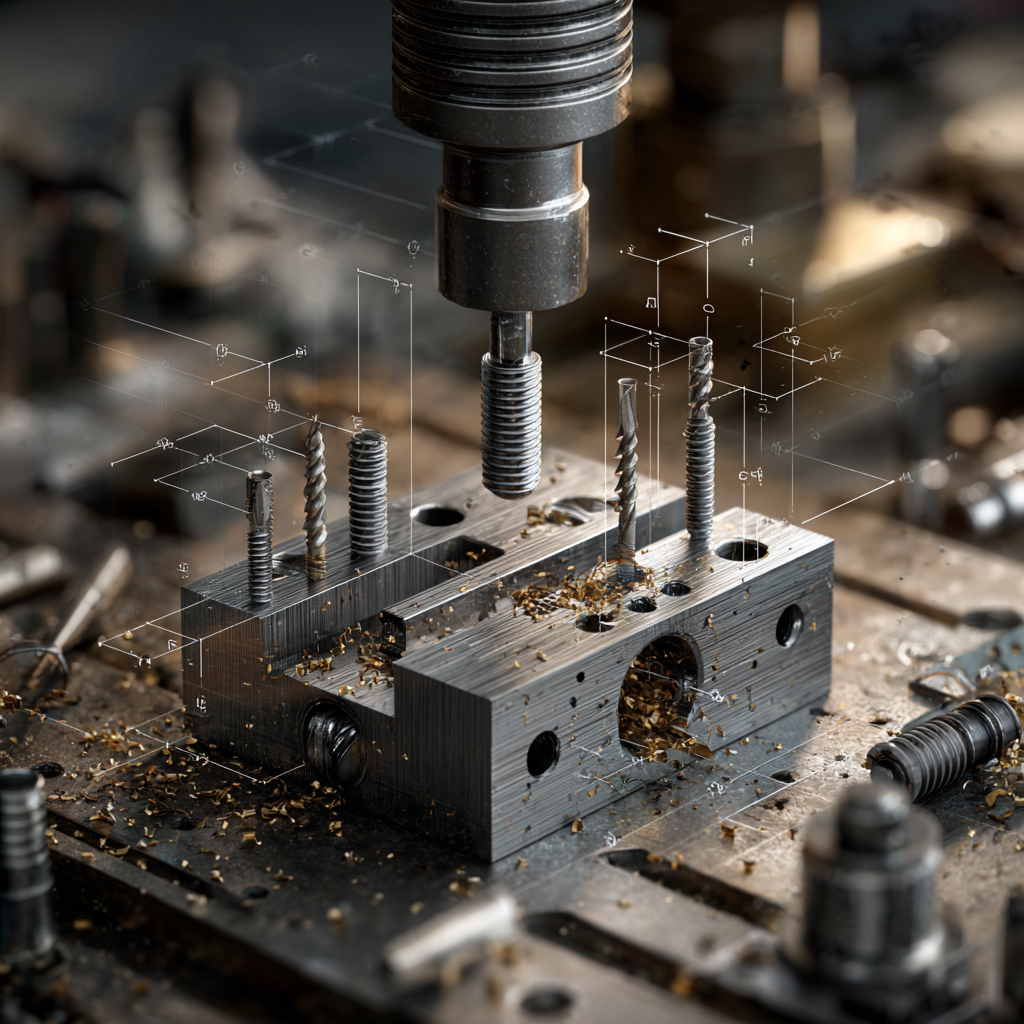

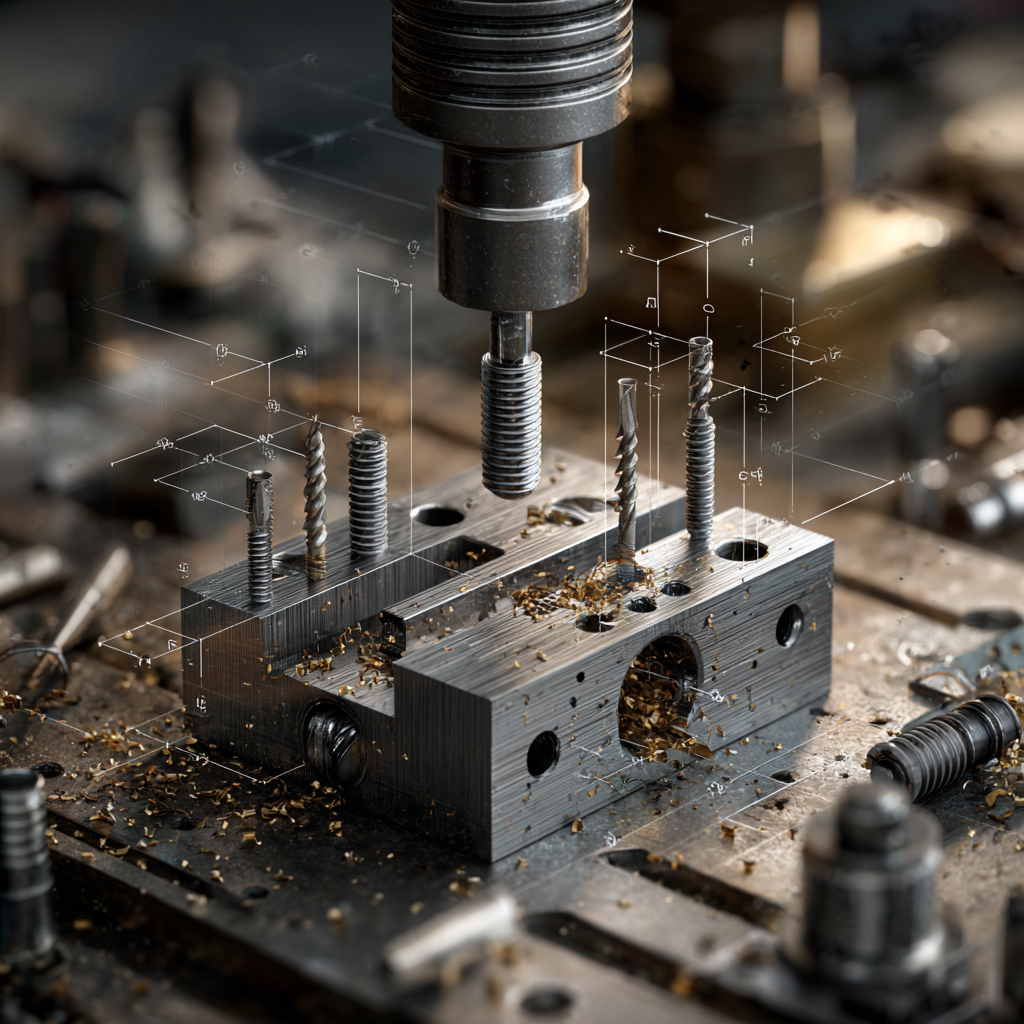

If dies create the external threads on bolts and rods, then taps are their natural counterpart cutting the internal threads that transform plain holes into functional nuts. Guided by DIN standards, taps ensure that every threaded connection is accurate, durable, and compatible worldwide.

DIN 352: Hand Taps

Hand taps are typically sold in a set of three:

-

Taper Tap – starts the threading process smoothly.

-

Plug/Intermediate Tap – cuts deeper into the hole.

-

Bottoming Tap – finishes the thread all the way to the bottom (useful for blind holes).

💡 Analogy: Like using progressively finer carving tools — each pass refines the groove until it becomes a perfect screw thread.

DIN 371 & 376: Machine Taps

Unlike hand taps, machine taps are designed for speed and consistency.

-

DIN 371: Standard shank machine taps for smaller sizes.

-

DIN 376: Longer, more robust machine taps for larger or deeper threads.

💡 Analogy: Imagine carving a groove in one single, precise motion instead of three careful passes. That’s the efficiency of a machine tap.

Why Taps Matter in Industry

✔️ Every threaded hole in engines, machinery, and mining equipment is cut with taps.

✔️ Enable secure fastening where bolts must hold under heavy loads.

✔️ Provide interchangeability — a screw made anywhere fits into a DIN-standard tapped hole.

From the smallest electronics to massive excavators, taps ensure connections you can trust.

Taps are simple-looking tools with a critical role: creating precise internal threads that hold the industrial world together. Backed by DIN standards, they guarantee global compatibility and reliability in every threaded joint.