In mining machinery, shafts transmit enormous amounts of torque — from conveyor drives to crusher rotors. But when torque varies dynamically, shafts are exposed to torsional vibrations, which can be just as dangerous as bending oscillations. If these vibrations align with the shaft’s critical angular speed, catastrophic failures may occur.

This blog explains how torsional vibrations work, why critical angular speed matters, and how engineers ensure safety in mining applications.

1. What Are Torsional Vibrations?

Torsional vibration is the oscillation of a shaft in its rotational direction caused by fluctuating torque.

Common causes include:

-

Sudden load changes in crushers or mills

-

Motor torque pulsations

-

Gear meshing irregularities

-

Shaft misalignment

Left unchecked, torsional oscillations can lead to cracks, fatigue, and coupling damage.

2. Critical Angular Speed

Critical angular speed (or natural torsional frequency) is the speed at which a shaft’s torsional natural frequency matches the frequency of excitation torque.

Formula for natural frequency (simplified for single mass system):

ωn=KtJ\omega_n = \sqrt{\frac{K_t}{J}}

Where:

-

ωn\omega_n = natural angular frequency (rad/s)

-

KtK_t = torsional stiffness of shaft

-

JJ = polar moment of inertia of rotating mass

✅ When operating speed approaches ωn\omega_n, resonance amplifies torsional oscillations.

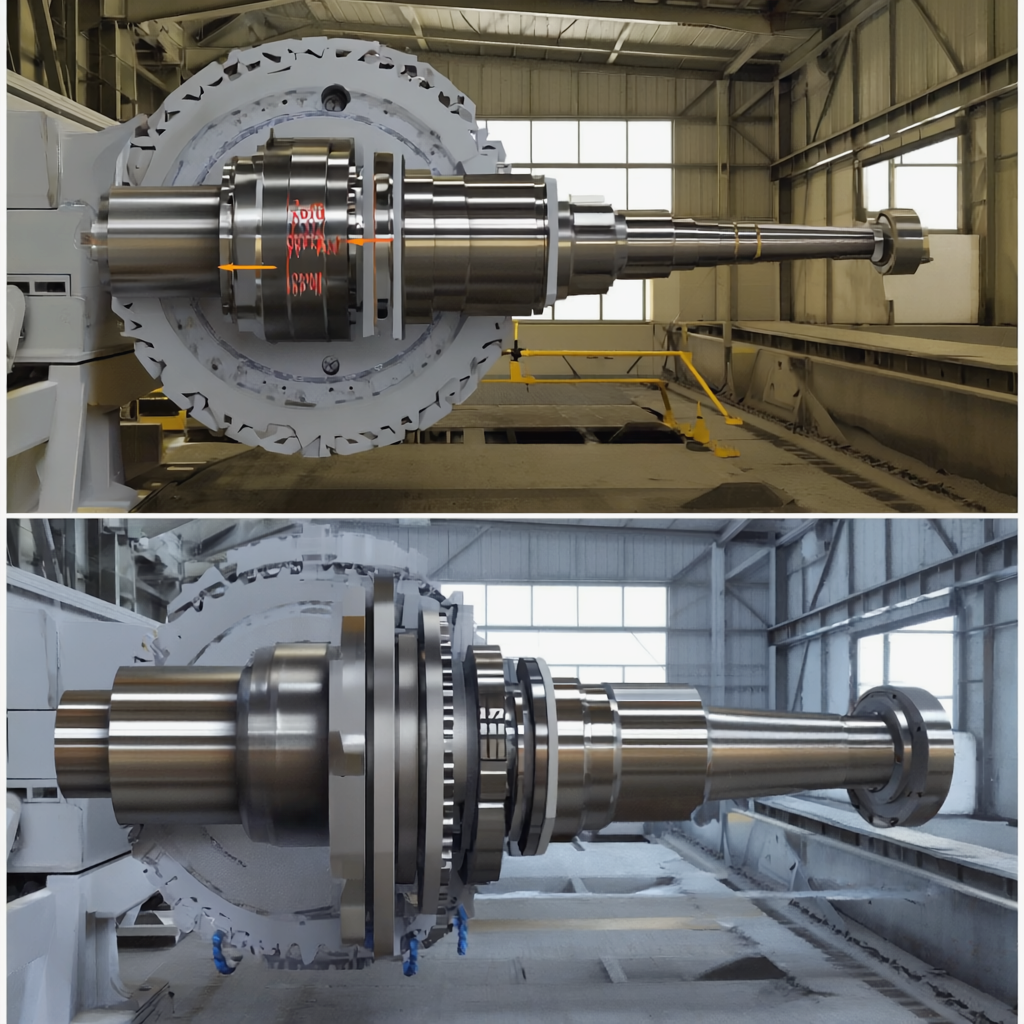

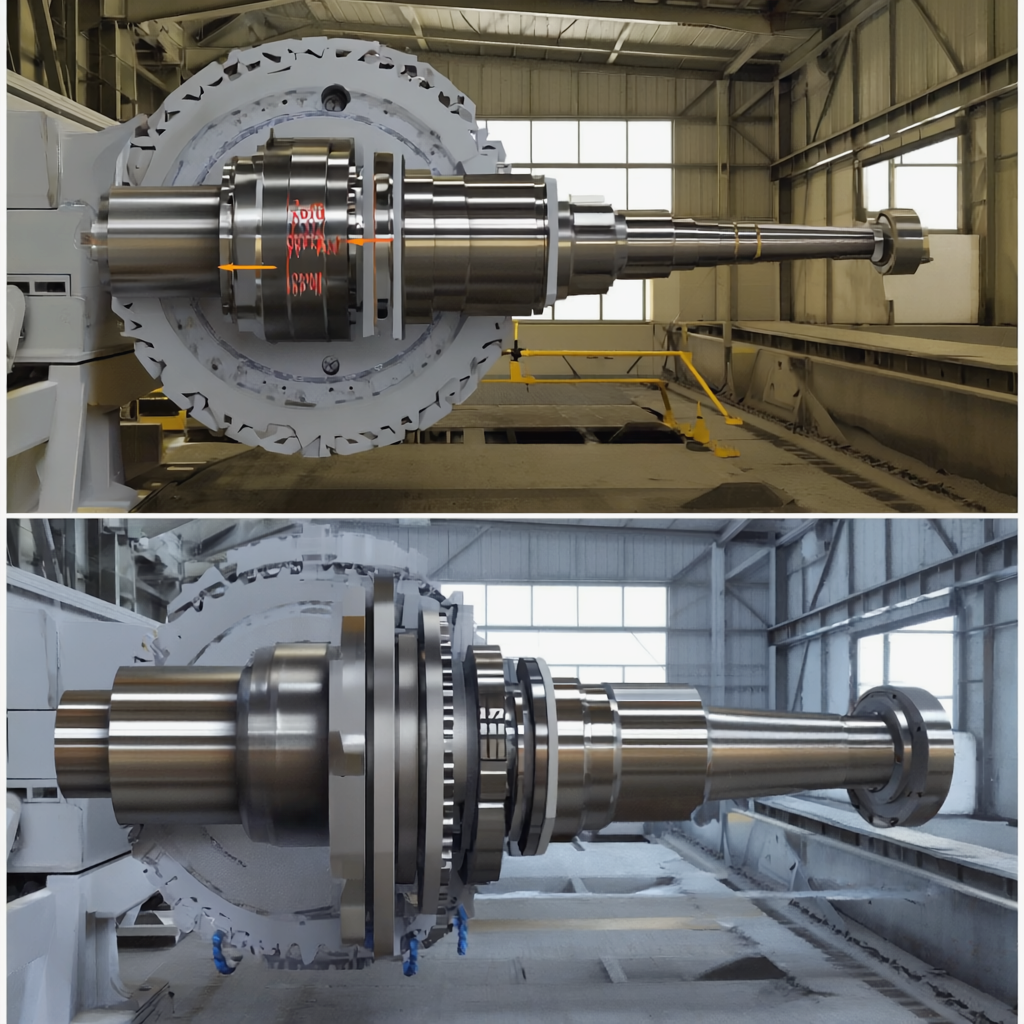

3. Real-World Example: Crusher Drive Shaft

-

Torque fluctuation from the crusher motor excites torsional vibrations

-

If shaft stiffness and inertia align at the wrong frequency, resonance can cause severe angular displacement

-

Solution: redesign shaft dimensions, use flexible couplings, or dampers

4. Engineering Strategies to Control Torsional Vibrations

✔️ Increase shaft stiffness to shift natural frequency

✔️ Use torsional dampers or flexible couplings to absorb energy

✔️ Perform finite element analysis (FEA) for complex, multi-mass systems

✔️ Ensure operational speeds stay well below or above the critical angular speed

5. Importance in Mining

Mining equipment often operates under cyclic and heavy torque variations. A shaft designed without considering torsional resonance risks:

-

Unexpected downtime

-

Costly component replacements

-

Safety hazards for operators

Torsional vibrations are an invisible but significant threat in rotating mining equipment. By calculating and controlling the critical angular speed, engineers can safeguard machinery, ensure smooth operation, and extend service life.