In steel fabrication, one millimeter can be the difference between a perfect fit and a critical failure.At Steltech Makina, precision…

Strength You Can Measure In steel manufacturing, quality isn’t assumed — it’s proven.Every beam, sheet, and rebar that leaves a…

In the world of heavy-duty industrial machinery, the performance of a machine depends heavily on the strength and engineering of…

In industrial environments, a crane is more than a lifting machine—it’s a core component of production continuity. When a crane…

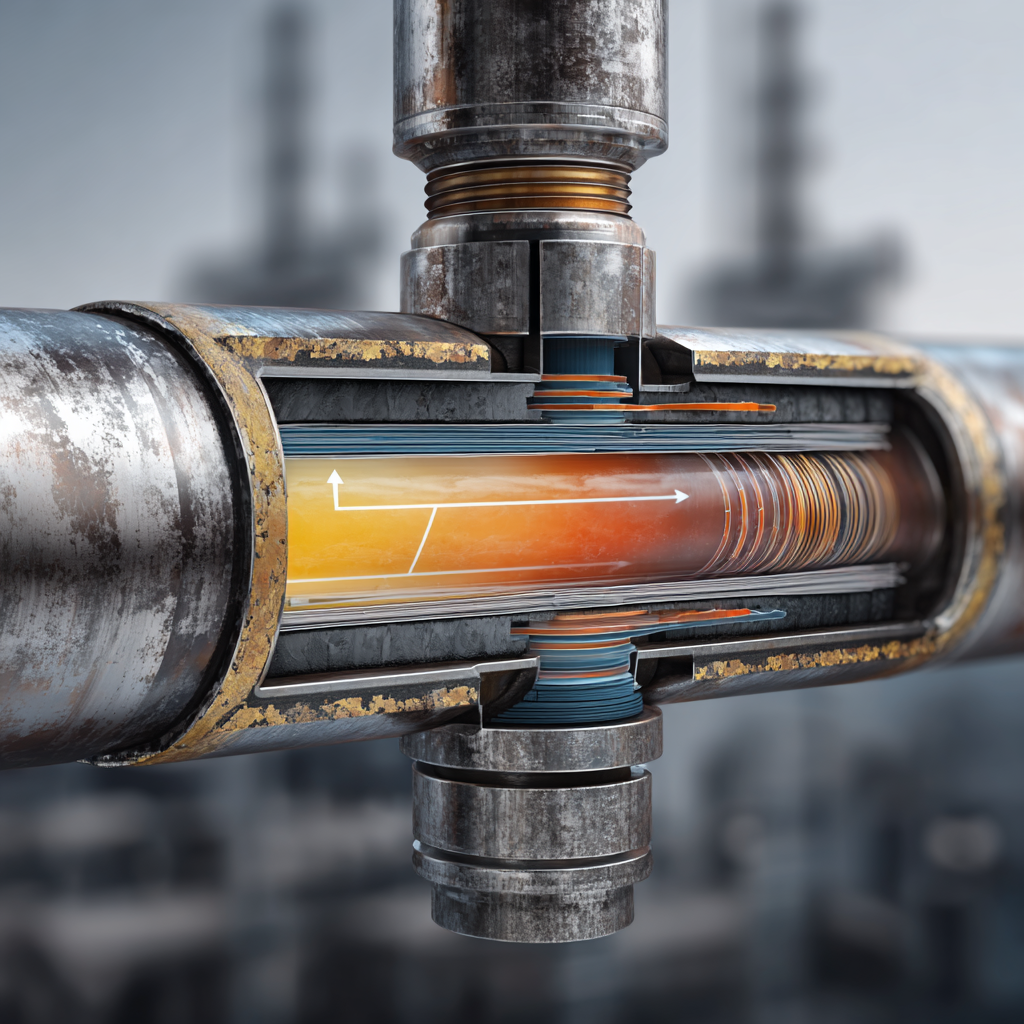

In continuous casting, the tundish is more than a reservoir — it is the first refinery that determines final steel…

Modern steelmaking is no longer powered by heat alone — it’s powered by data.At Steltech Makina, furnace operations have entered…

In steel production, safety is not a department — it’s a culture. During commissioning, when new systems and equipment are…

At Steltech Makina, we know that bringing a steel furnace to life isn’t just about switching it on — it’s…

The Beating Heart of Every Steel Plant In every integrated steel plant, the blast furnace stands as the beating heart …

Climbing the Ladder of Strength Not all steel is created equal — and in the world of reinforcement, grades define…

The Hidden Strength Beneath Every Structure Every skyscraper, bridge, and tunnel stands on one unsung hero — reinforcing steel bars,…

Safety by Design In steel plants, safety isn’t just a priority — it’s a requirement for survival.High-voltage systems power massive…

The Power Behind Progress At Steltech Makina, we know that steel production runs on power — both literally and figuratively.A…

When it comes to precision, consistency, and trust in engineering, few names carry as much weight as DIN — Deutsches…

Every great creation starts with a recipe and steel is no exception.From bridges and skyscrapers to cars and cargo ships,…

Steel is the silent strength behind our modern world. From the fork you use at breakfast to the bridges that…

Bringing a steel furnace to life is as fascinating as it is demanding. Unlike flipping a switch, reaching full production…

In the heart of every steel plant, immense forces collide — heat, energy, and motion. These environments, while essential for…

Cold commissioning is the essential first step in bringing a steel plant to life. At Steltech Makina, we ensure every system is tested safely and systematically, reducing risks, saving time, and guaranteeing peak performance before production begins.

The ISRI Scrap Specifications Circular sets global recycling standards for metals, plastics, paper, and more. At Steltech Makina, our shredders, balers, and separators are engineered to meet these specs, ensuring efficiency, purity, and sustainability in every recycling process.

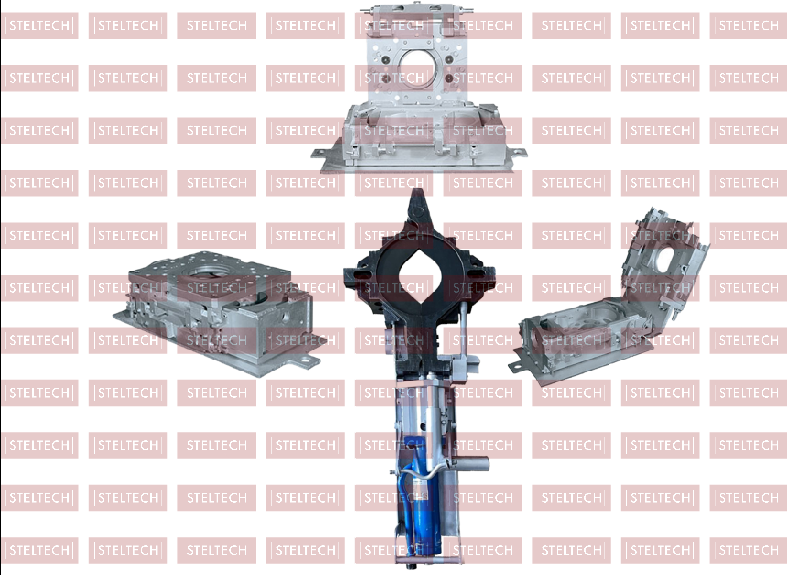

In the fast-paced world of steel production, where precision and time are critical, ultra-fast nozzle changers are transforming continuous casting….

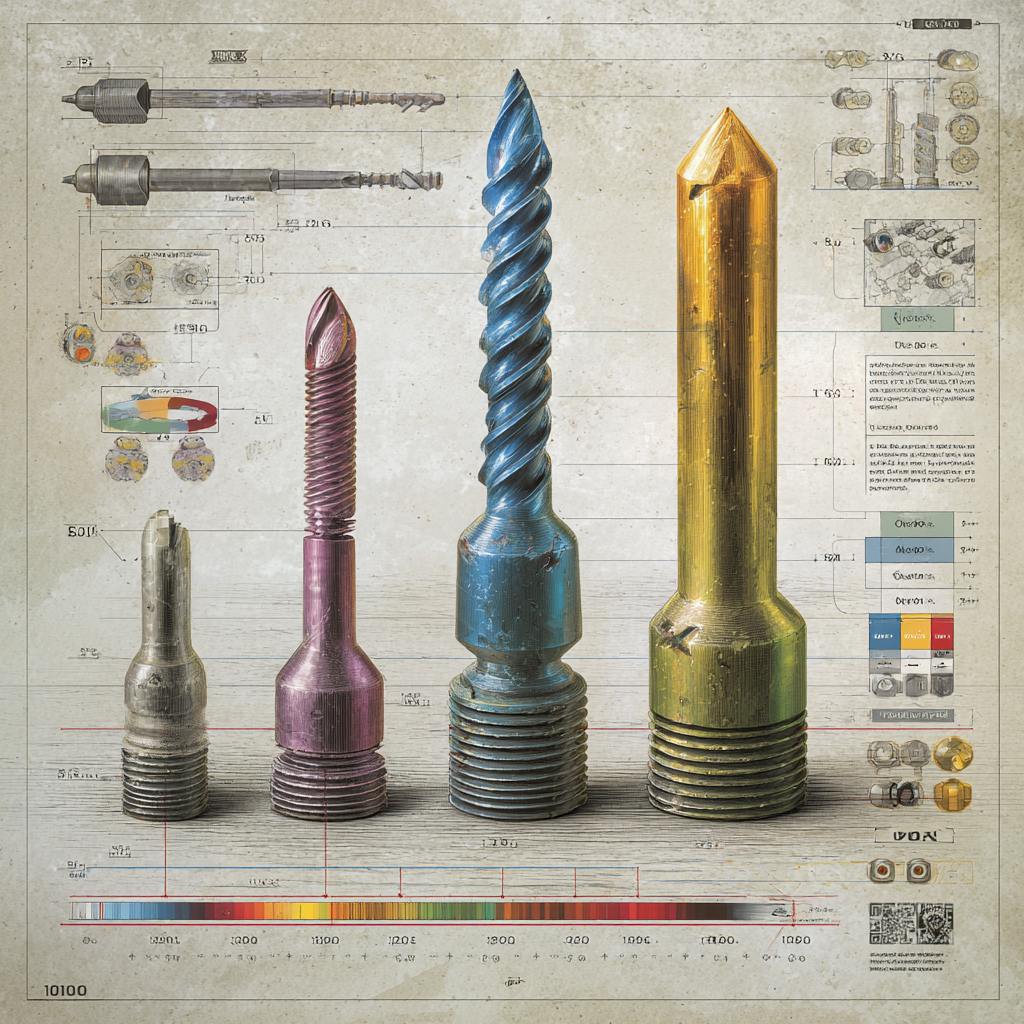

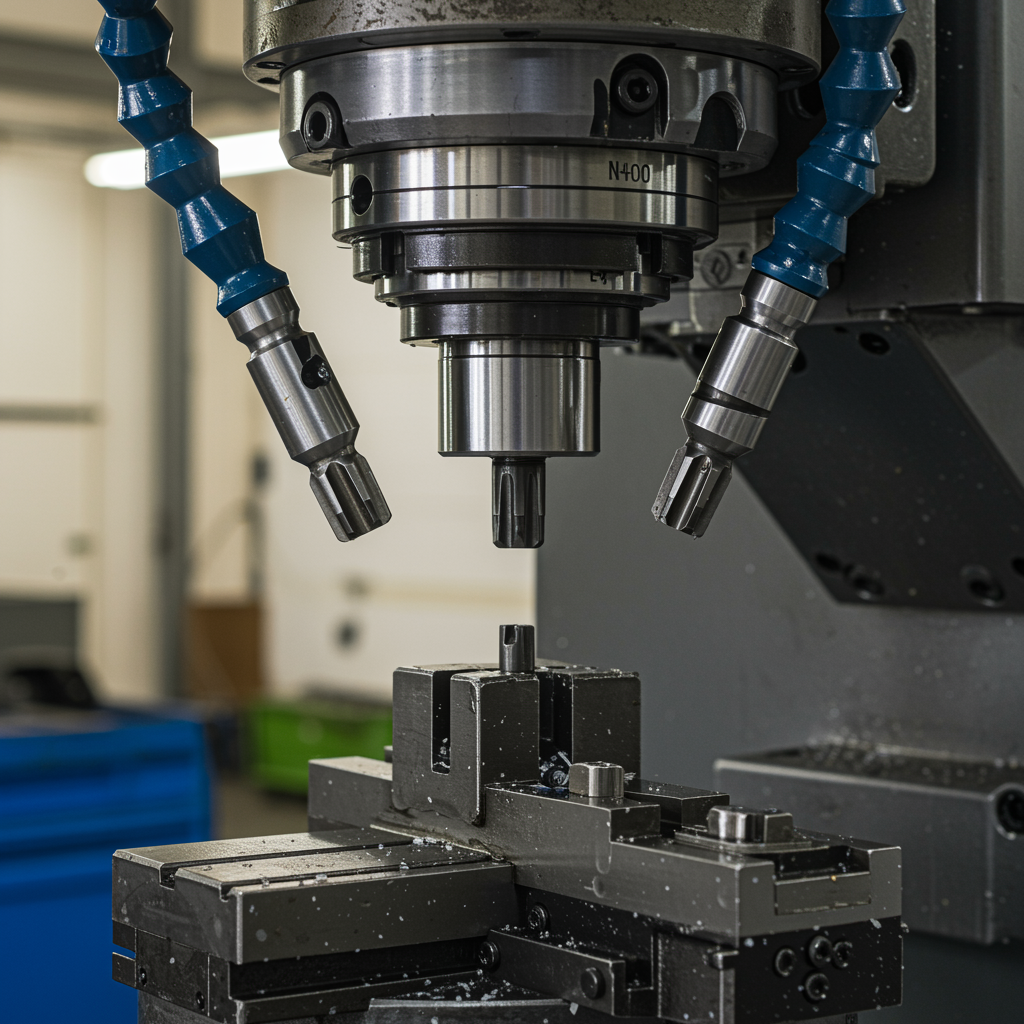

While standard drills and countersinks handle most machining tasks, specialized hole tools take precision and efficiency to the next level….

Taps and dies are the unsung heroes of engineering. They cut the precise threads that make bolts, screws, and nuts interchangeable worldwide — keeping mining machines, cars, and factories running smoothly.

Drills may create holes, but for true precision and durability, countersinks and center drills take the stage. These tools refine, guide, and prepare holes so that fasteners fit perfectly and machining remains accurate.

If dies create the external threads on bolts and rods, then taps are their natural counterpart cutting the internal threads…

Threads are everywhere from the screws in your phone to the massive bolts holding mining equipment together. But how are these precise spiral grooves created? The answer lies in taps and dies, guided by DIN standards.

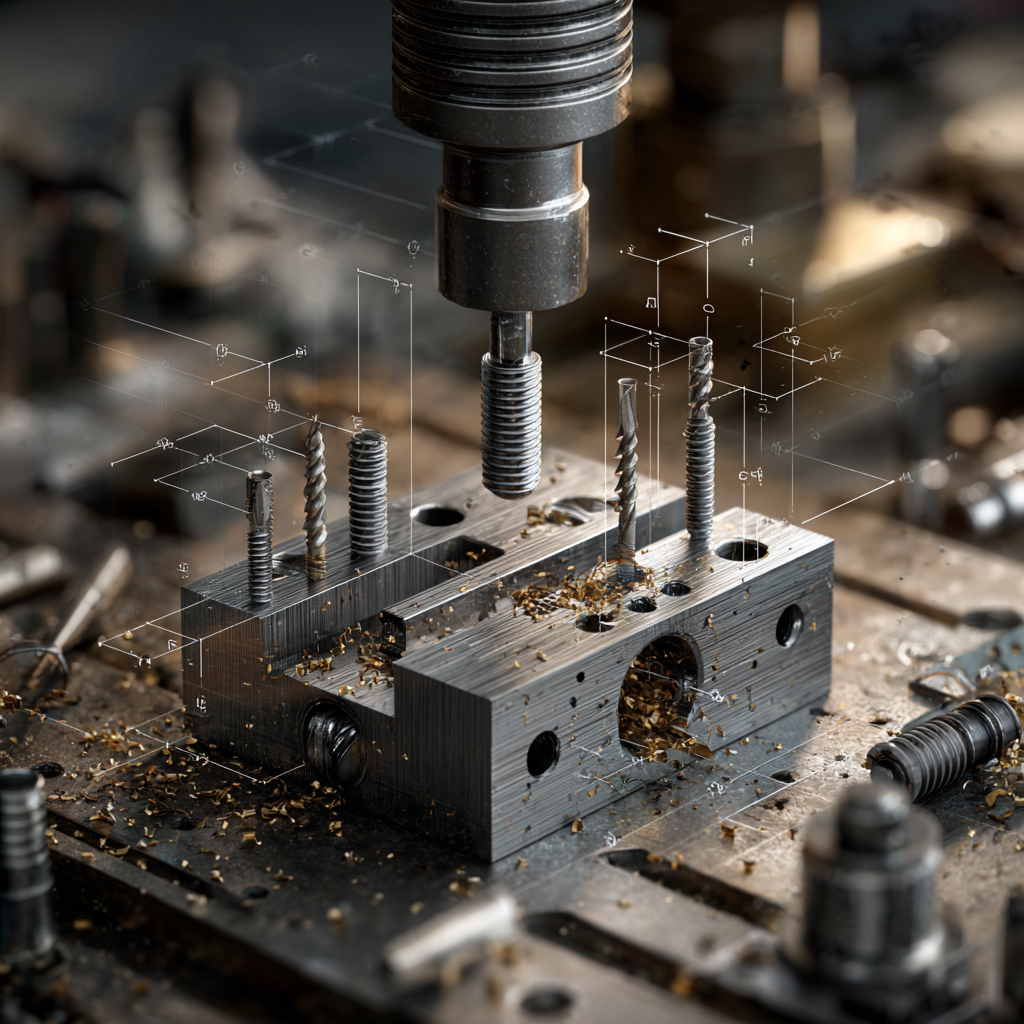

When it comes to machining steel, one of the most common tasks is creating precise holes. From simple fasteners to complex machine assemblies, holes must be accurate, smooth, and reliable. This is where drills and reamers — guided by DIN standards — play a central role.

Behind every powerful machine tool lies a simple question: how does the tool connect securely to the machine? This is where standards like DIN 10 and DIN 138 come in. They define the dimensions of shanks and sockets the “handshake” between tools and machines.

When it comes to shaping and machining steel, precision is everything. A drill bit labeled “5mm” must always measure 5mm, no matter who manufactured it. This is where DIN standards (Deutsches Institut für Normung) come into play. Established in Germany, DIN ensures that tools and components are consistent, reliable, and interchangeable.

Many rotating shafts in mining and industrial equipment run on journal bearings also known as plain bearings. Unlike ball bearings, which use rolling elements, journal bearings rely on sliding contact between the shaft and bearing surface.They are strong, simple, and cost-effective, but they face two constant challenges: friction and wear.