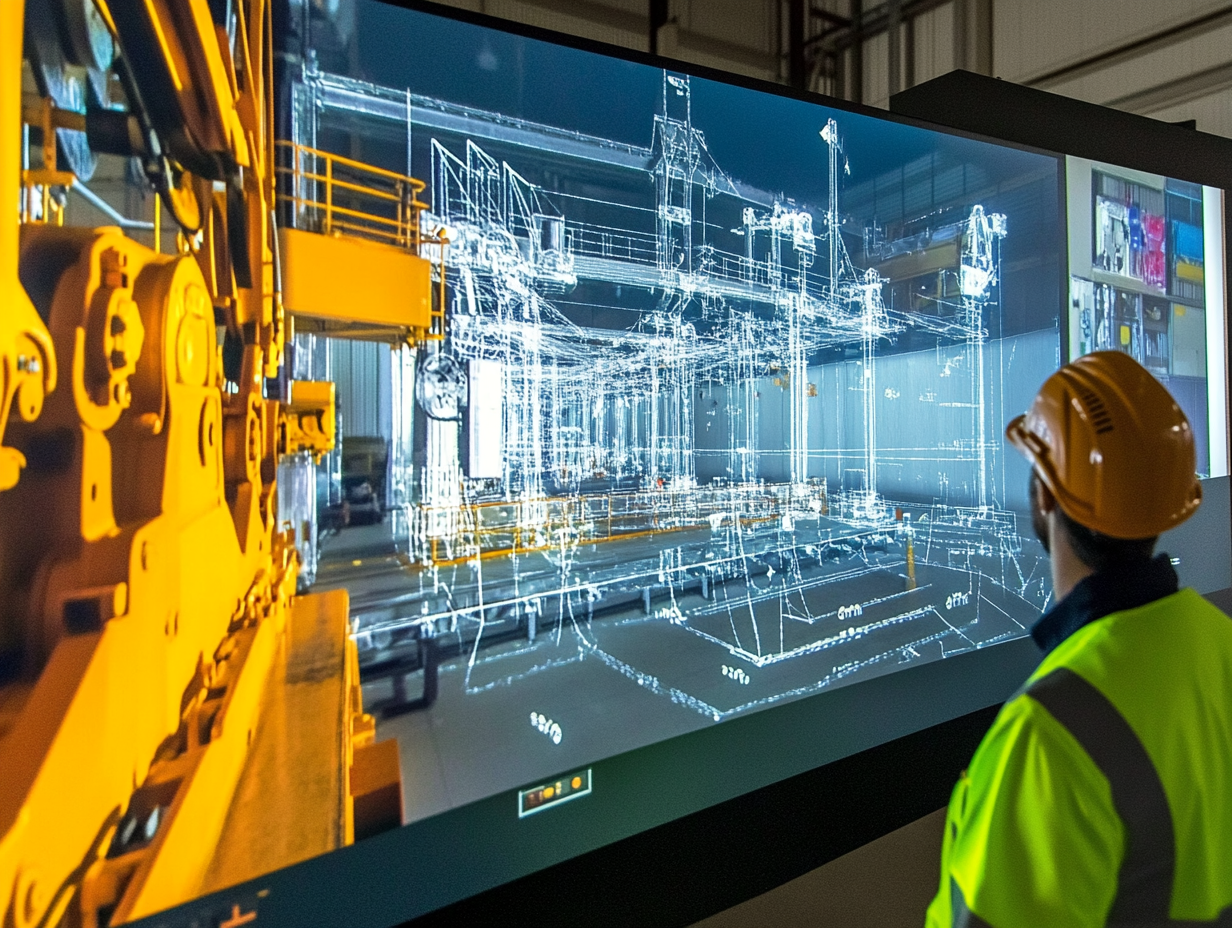

Selecting the correct crane for a mining or industrial project isn’t just about lifting capacity — it’s about matching the machine to the expected usage intensity. This is where the concepts of load groups (B classes) and duty classes (H classes) come into play. These classifications help engineers and decision-makers choose cranes that won’t just work — they’ll last.

In the mining and heavy machinery industries, safety isn’t optional — it’s engineered into every bolt, beam, and weld. One of the most critical concepts in structural crane design is the use of safety factors. These mathematical buffers ensure that structures withstand not only known loads but also unexpected forces, imperfections, and usage variations. In essence, safety factors protect lives and investments.

In crane design — especially in heavy industries like mining and infrastructure — selecting the right steel is crucial. Two of the most commonly used structural steels are St37-2 and St52-3. Each has unique mechanical properties that make it suitable for different applications, environments, and load conditions. Understanding their differences is essential for engineers, designers, and project managers aiming to build safe, durable, and cost-effective cranes.

Understanding crane load conditions is essential in designing safe and reliable lifting systems — especially in demanding fields like mining, construction, and logistics. These classifications (H, HZ, and HS) define the environmental and operational stresses a crane is expected to handle. Selecting the correct condition is key to ensuring structural integrity and operational longevity.

Steel construction plays a fundamental role in ensuring the structural integrity, operational efficiency, and safety of cranes used in various industries, from mining to logistics. As one of the most critical engineering aspects of lifting systems, a solid grasp of steel construction principles can significantly influence design decisions and long-term performance.

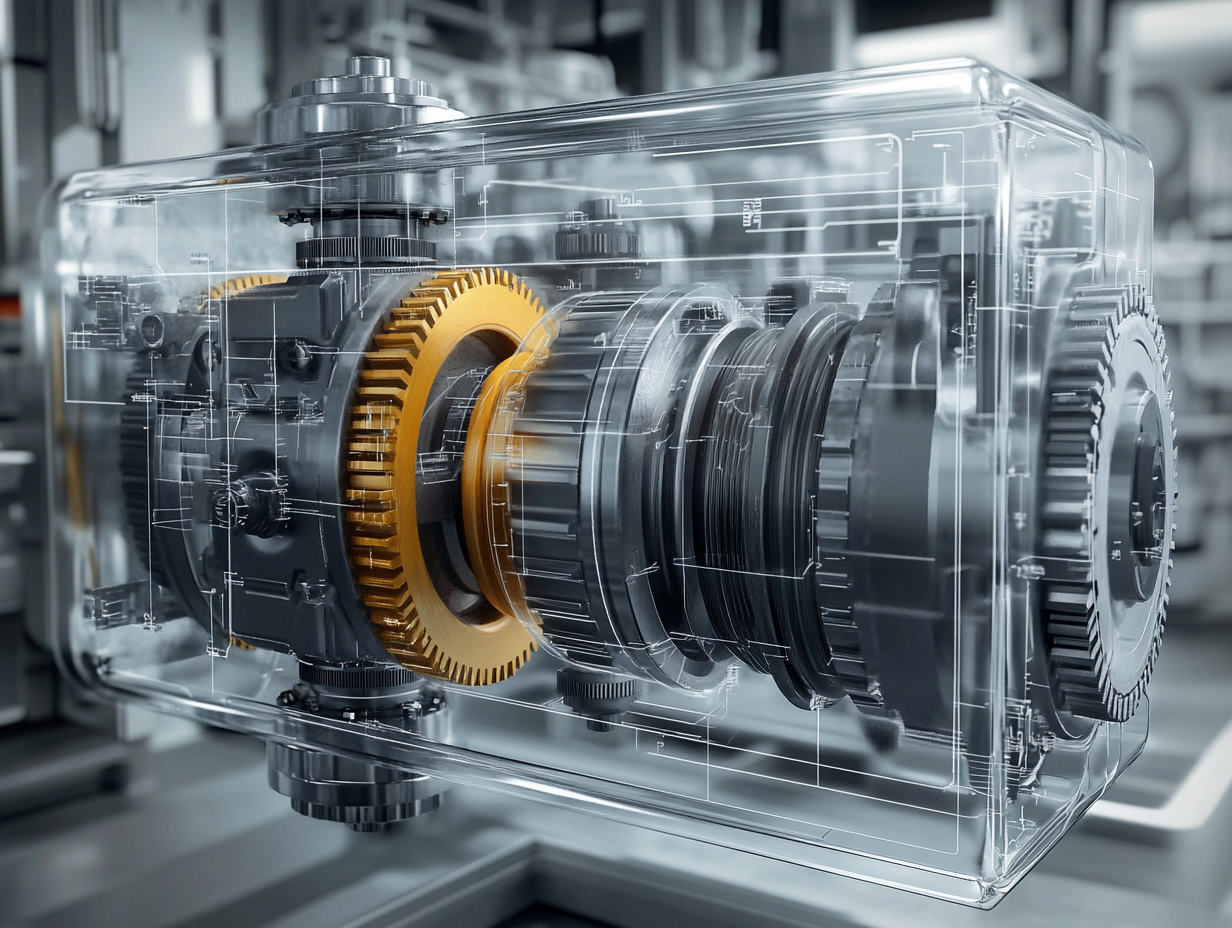

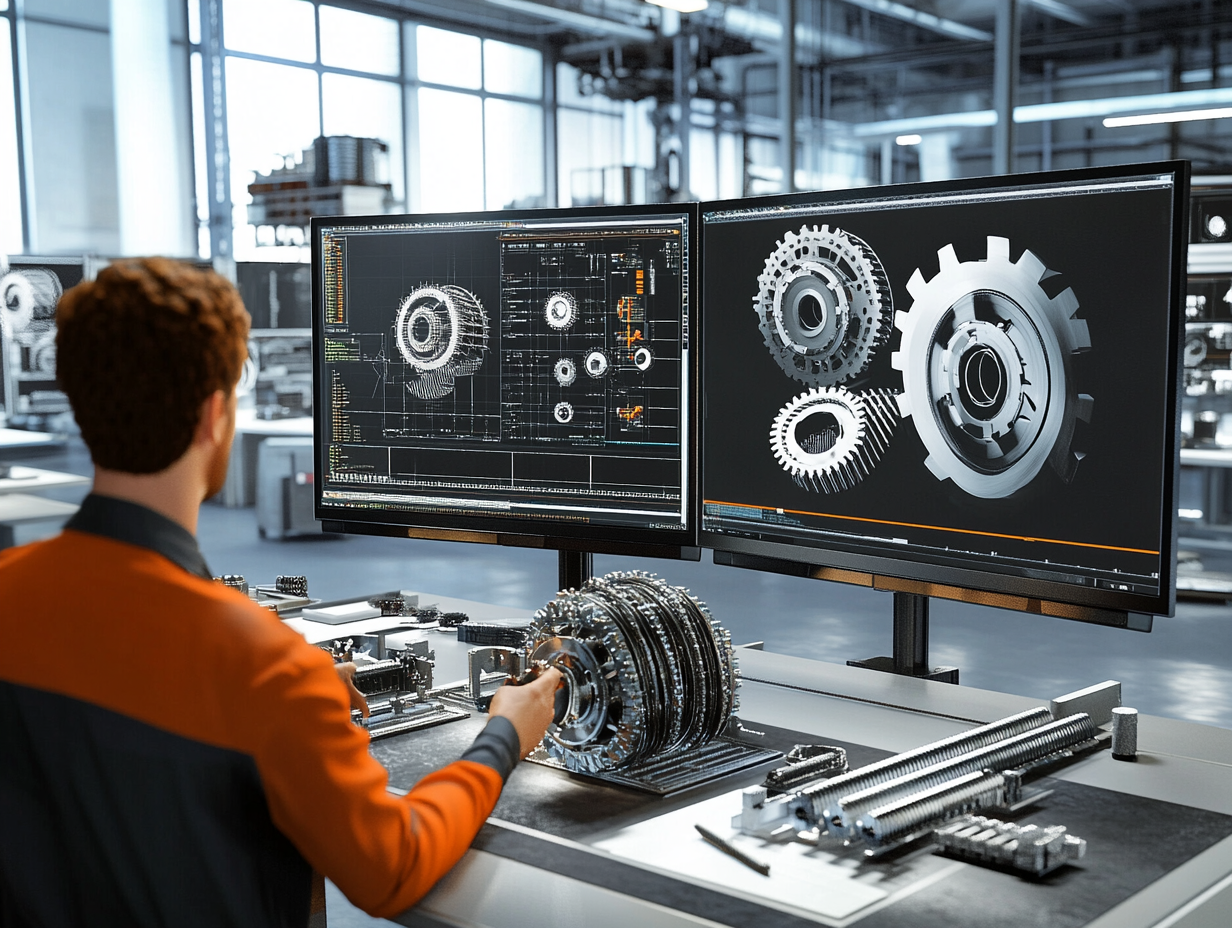

Gear pumps are widely used in hydraulic systems, offering reliability and simplicity in fluid transfer. In marine gearbox systems, gear pumps play a critical role in circulating oil under pressure. This blog explores the design and flow performance of gear pumps using CAD-based modeling, particularly focusing on how gear width and profile selection impact volumetric flow.

Non-preloaded bolted connections are widely used in steel structures, particularly in applications where high-strength clamping forces are not required. These connections rely on bearing resistance and shear capacity, making them suitable for low to moderate load conditions. In this blog, we explore the mechanical behavior, strength calculations, and best practices for designing non-preloaded bolted connections.

Bolts are a critical component in steel construction, used for securing connections, distributing loads, and maintaining structural integrity. Choosing the right bolt type ensures safety, durability, and performance in bridges, buildings, industrial plants, and machinery. This blog explores the different types of bolts, their characteristics, and applications in steel structures.

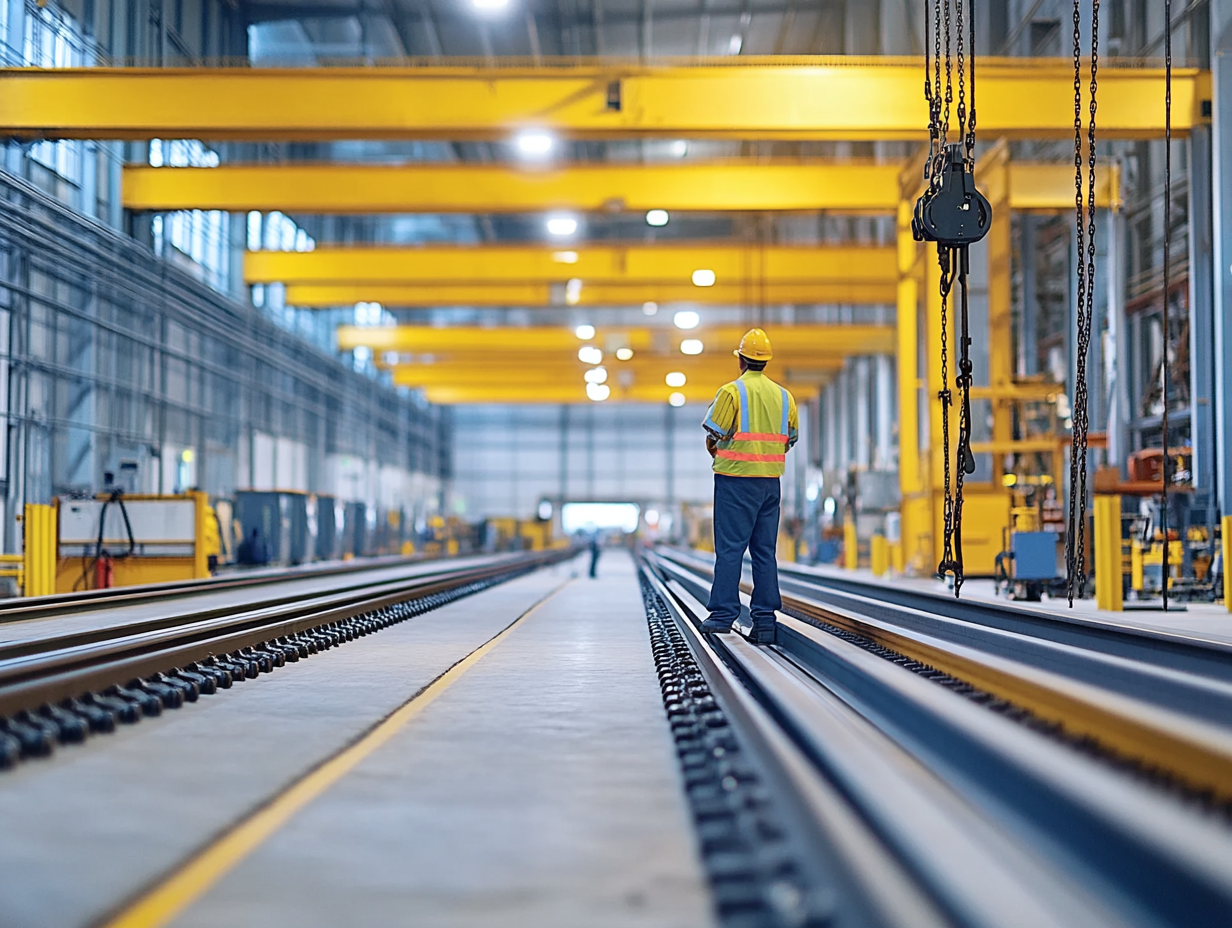

The choice of rail profile significantly affects crane movement, load distribution, and long-term operational efficiency. Selecting the wrong profile can result in excessive wear, misalignment, and high maintenance costs. This blog explores how different rail profiles influence crane performance and what factors to consider for optimal selection.

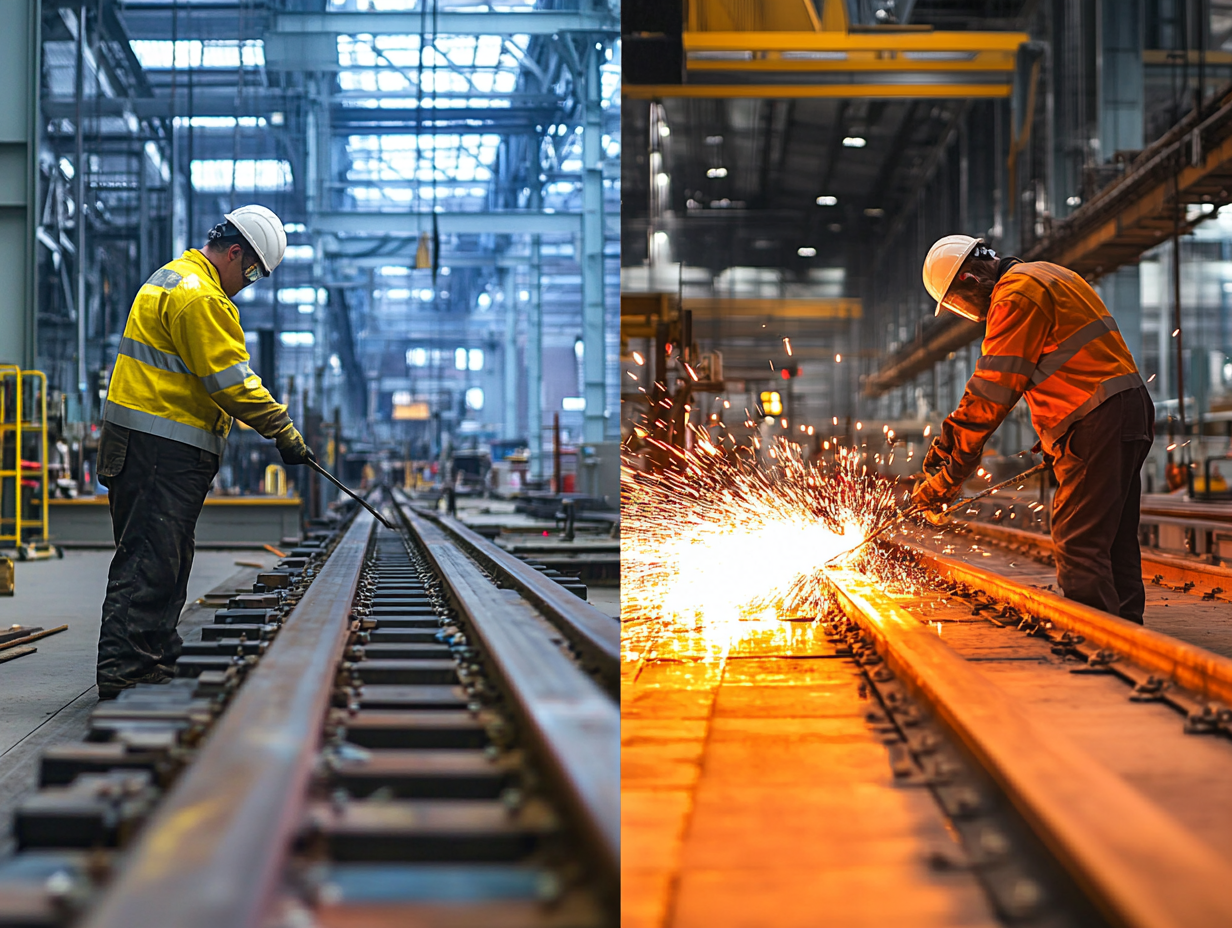

Crane rail maintenance is essential for ensuring safety, efficiency, and long-term durability. Companies often choose between preventive maintenance, which focuses on scheduled inspections and early issue detection, and reactive maintenance, which addresses failures as they occur. This blog explores the advantages and risks of both approaches, helping you implement an optimal rail maintenance strategy.

Crane systems require a strategic balance between cost efficiency and long-term durability. Overdesigning leads to unnecessary expenses, while underdesigning results in premature failures and high maintenance costs. This blog explores economic design principles that ensure optimal performance, longevity, and cost-effectiveness in crane systems.

Crane tracks are subject to complex forces, including torsional stress, lateral loads, and dynamic weight shifts. Poor design can lead to uneven load distribution, track misalignment, and premature wear. This blog explores torsion effects, force distribution challenges, and best design practices to enhance stability and operational efficiency.

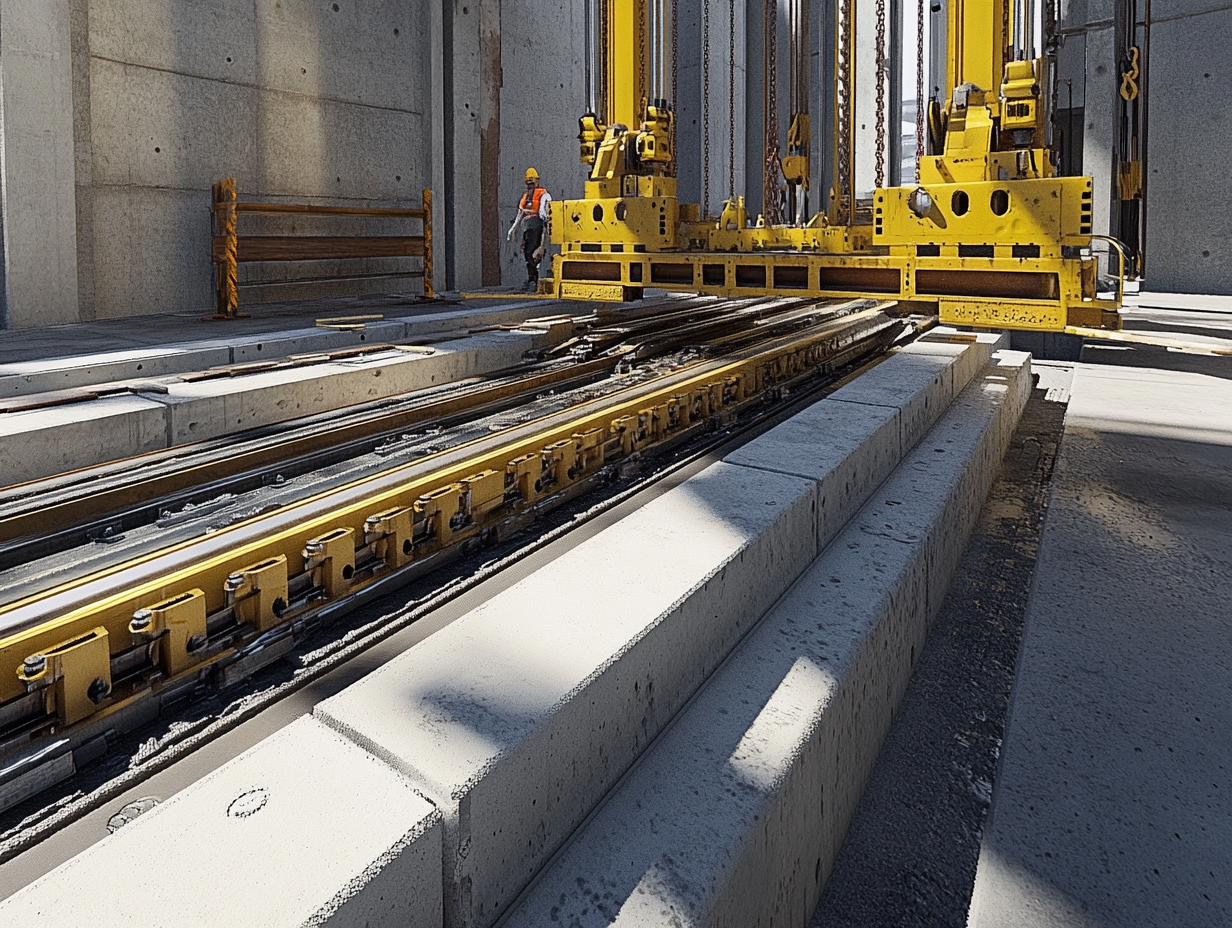

Proper installation of crane track rails is essential for ensuring alignment, structural integrity, and long-term durability. Poorly installed rails can lead to misalignment, excessive wear, and increased maintenance costs. This blog explores the best installation techniques, welding methods, and industry standards to follow for optimal crane track performance.

Crane rails are subjected to continuous mechanical stress, heavy loads, and environmental factors, which can cause wear and deformation over time. Without proper management, these issues can lead to misalignment, increased maintenance costs, and safety risks. This blog explores the causes of rail wear, strategies to minimize deformation, and best practices for extending rail lifespan.

Crane tracks used in open yard environments face unique challenges, including weather exposure, temperature fluctuations, and increased lateral forces. Unlike indoor installations, these tracks must be engineered for durability, stability, and resistance to environmental conditions. This blog explores the key factors in designing crane rail systems for open yards and best practices for ensuring long-term performance.

Ensuring stability and fatigue resistance in crane tracks is essential for maintaining safety, longevity, and operational efficiency. Over time, repeated loading and environmental factors can cause material fatigue, misalignment, and structural degradation. This blog explores the critical factors affecting stability, common fatigue issues, and best practices for preventing premature failures.

Selecting the right crane rail profile is essential for ensuring stability, load-bearing capacity, and durability in industrial operations. While DIN 536 A, DIN 536 F, and standard railway rails are commonly used, each has distinct design characteristics and applications. This blog explores their differences, advantages, and ideal use cases.

Flat bar crane rails, also known as laminated rails, are a widely used alternative to traditional crane rail profiles. These rails are particularly favored in light to medium-duty applications, offering flexibility and cost-effectiveness. However, they also come with specific limitations that must be considered when designing crane track systems. This blog explores the pros and cons of flat bar crane rails and their ideal applications.

Crane rail selection is a critical decision that directly impacts safety, efficiency, and long-term durability in industrial operations. Choosing the wrong rail can lead to premature wear, misalignment, and costly maintenance. This blog explores the essential factors to consider when selecting the right crane rail for your system.

Proper crane rail installation and bedding systems are essential for ensuring stability, durability, and reduced maintenance costs. Incorrect installation or improper bedding can lead to wear, deformation, and misalignment. This blog explores crane rail installation techniques, bedding systems, and key considerations for optimal performance.

Crane tracks must handle not only vertical loads but also lateral forces and torsion (twisting effects). Insufficient torsional resistance or uncontrolled lateral forces can cause rail deformations, crane instability, and serious operational issues. This blog explores how torsion is managed in crane tracks and the methods used to control lateral forces for optimal stability.

Crane tracks are subjected to heavy loads daily, making stability and fatigue analysis essential. Poorly designed crane tracks can lead to deformation, system failures, and costly downtime. This blog explores best practices for ensuring track stability and fatigue resistance.

Crane tracks are critical for moving heavy loads in industrial facilities. Their design varies based on crane type and operational requirements. Generally, single-span and multi-span crane track systems are used. In this blog, we compare these two systems, exploring their advantages, disadvantages, and best-use cases.

For crane tracks to operate safely and efficiently, they must meet specific tolerance standards. Misaligned rails can cause excessive wear on crane wheels, rail bending, and system failures.

The safety and efficiency of crane tracks depend on the accuracy of the structural construction. The quality of steel structures, connection details, and design tolerances ensure long-lasting and trouble-free operation.

Before delving into gear design, it is essential to understand the fundamental terminology. This article covers the most important concepts in gear terminology.

Crane rails are designed to suit various industrial applications, and their proper selection directly impacts the performance, safety, and longevity of crane systems.

Crane tracks are engineering marvels designed to safely transport heavy loads. However, the reliability and durability of these systems depend heavily on the materials used and the design choices made.

Crane tracks are essential components of industrial systems, enabling the safe and efficient movement of heavy loads. The proper selection and standard-compliant design of crane rails are crucial for both performance and safety.

The successful implementation of FMEA (Failure Modes and Effects Analysis) requires well-structured templates and adherence to standards. These tools enhance consistency, facilitate collaboration across teams, and standardize processes.