In modern industrial processes, improving quality, ensuring safety, and reducing costs have become more critical than ever. FMEA (Failure Modes and Effects Analysis) is a powerful tool used to achieve these goals.

FMEA (Failure Modes and Effects Analysis) is a systematic method for identifying and managing risks in complex systems. The effectiveness…

FMEA (Failure Modes and Effects Analysis) is a critical tool in risk assessment. However, its effectiveness relies on meeting specific success criteria.

FMEA (Failure Modes and Effects Analysis) provides a systematic approach to identifying and mitigating risks. The success of this analysis depends on selecting and applying the right methods.

FMEA (Failure Modes and Effects Analysis) is a powerful method for identifying potential failure modes and preventing them systematically. However, its effectiveness depends on the proper implementation steps and a well-structured organizational setup.

FMEA (Failure Modes and Effects Analysis) is a versatile method adaptable to various processes and systems. It is categorized into three main types: System FMEA, Design FMEA, and Process FMEA.

FMEA (Failure Modes and Effects Analysis) is a cornerstone of risk management, analyzing potential failure modes and their effects. However, like any powerful tool, it comes with both advantages and limitations.

In modern manufacturing, preventing errors, enhancing quality, and ensuring customer satisfaction are more critical than ever. FMEA (Failure Modes and Effects Analysis) is a method designed to analyze potential failures and their effects on systems, making it a key tool for optimizing risk management.

In modern manufacturing, well-prepared and standardized documentation plays a critical role in improving efficiency and minimizing errors. Manufacturing documents contain detailed technical drawings and standardized information used throughout the production process.

Risk management is one of the most critical elements in modern industrial processes. Fault Tree Analysis (FTA) is an effective method to identify the root causes of potential failures and their impacts on complex systems. This analysis enables proactive problem-solving and strategic risk mitigation.

Bending is a crucial step in metal forming, but post-bending welding plays an equally vital role in enhancing the durability and functionality of the final product. Proper welding applications ensure the structural integrity of materials while meeting safety and quality standards.

The relationship between material thickness and bending radius is essential for achieving quality and durable production in metalworking. Accurate calculations minimize the risk of cracking while ensuring precision in dimensions.

Hot bending is a vital technique in metal forming, especially for shaping tough and high-strength materials. By heating the material to an optimal temperature, this method enhances elasticity, reduces cracking risks, and enables the creation of complex designs.

Cold bending is a critical process that allows for precise shaping of metals at room temperature. Accurate dimensional calculations ensure the integrity, durability, and functionality of the final product.

In construction projects, properly prepared documents are essential for ensuring success. Construction documents serve as the foundation for guiding the project team from the design phase to production. These documents maintain standards and improve communication across all stages of the project.

In metal forming processes, bending and welding operations play a crucial role in determining the durability, aesthetics, and functionality of a product. Post-bending welding, in particular, helps maintain structural integrity and ensures the design’s functionality. Improper management of these processes can lead to cracks, deformities, and production errors.

In metal forming and sheet processing industries, the relationship between material thickness and bending radius is a cornerstone of production quality. Incorrectly calculated bending radii can lead to material cracking, deformation, or structural failure.

Material thickness and bending radius are critical factors in the manufacturing of durable and high-quality products. Incorrectly calculated bending radii can lead to cracking, deformation, or structural failure, compromising the integrity of the product

ot bending is a critical metalworking technique that allows for the shaping of materials that are difficult to form under normal conditions. By heating metals to a specific temperature, this method enhances their elasticity and prevents issues such as cracking or deformation. Hot bending is widely used in industries that require durable and precisely shaped components, such as aerospace, automotive, and energy.

Cold bending is a crucial process in the manufacturing of metal parts, where materials are bent at room temperature to achieve the desired shape. It is widely used in industries that require high precision and functional designs. Proper dimensional calculations during cold bending are essential to ensure that parts are accurate, safe, and meet design specifications.

Edge bending is an essential process in the production of technical components and everyday items. This technique not only improves the durability of materials but also enhances their aesthetic and ergonomic properties. Whether performed through mechanical methods, casting, or forging, edge bending ensures functionality and safety.

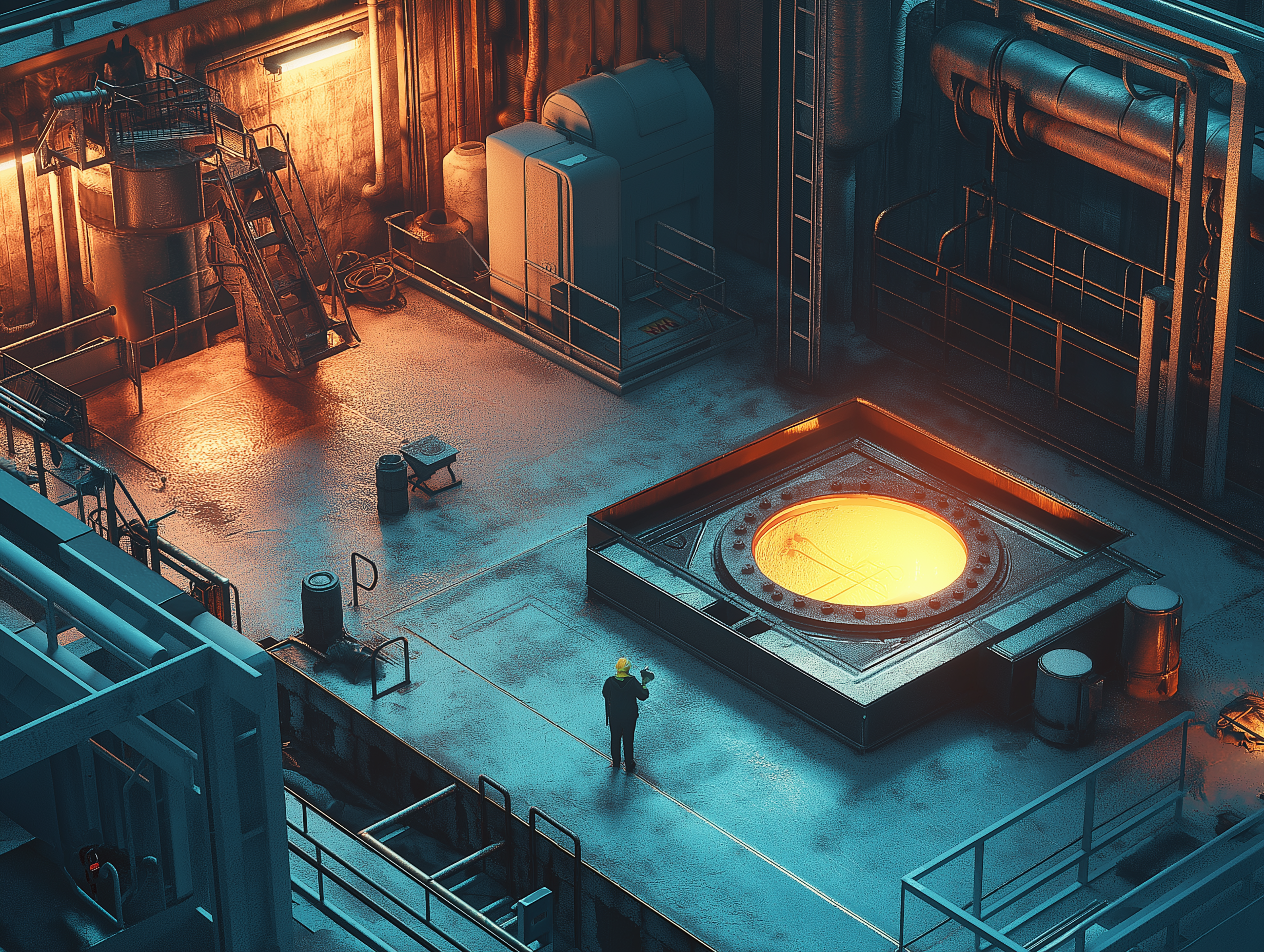

In casting production, achieving high-quality results goes beyond design and manufacturing. Testing and inspection processes are essential for ensuring the durability, performance, and compliance of cast parts with international standards. These processes help identify flaws early and enhance the final product.

Corrosion prevention is vital to extend the lifespan of cast parts and improve their resistance to environmental factors. Parts exposed to outdoor conditions or chemicals can deteriorate quickly without proper protection.

In casting production, achieving a high-quality final product is not solely dependent on proper design and manufacturing processes. Testing and inspection are crucial for ensuring the performance and durability of cast parts. These processes detect production flaws and enhance product quality.

Evolving technology has paved the way for innovative casting techniques that allow more complex designs, higher quality, and cost advantages in production. These advanced methods are essential in industries like aerospace, medical, and automotive.

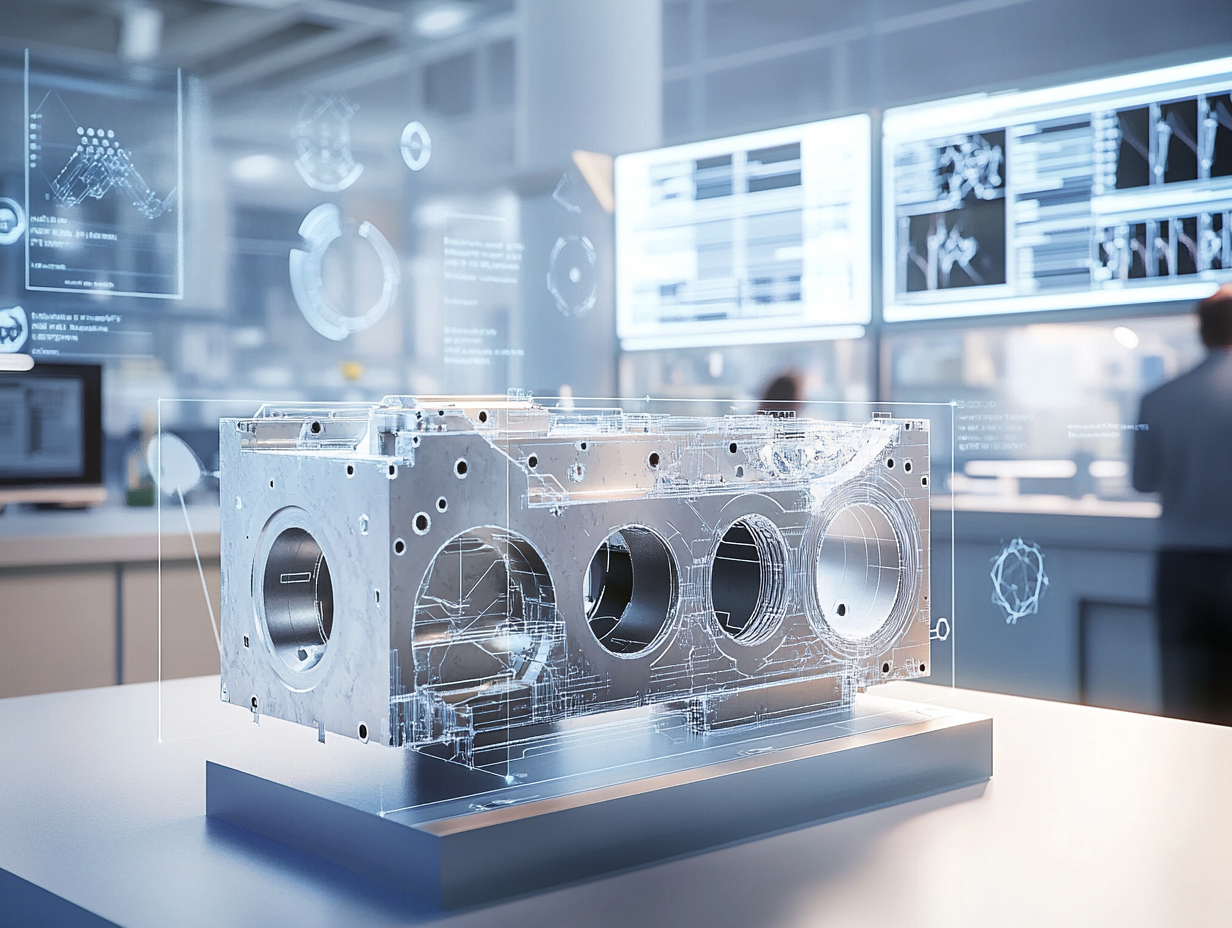

In casting production, technical drawings and checklists play a vital role in ensuring product quality and manufacturing efficiency. A well-prepared technical drawing not only conveys the product design but also helps identify potential issues in advance. Checklists, on the other hand, maintain standards throughout the production process.

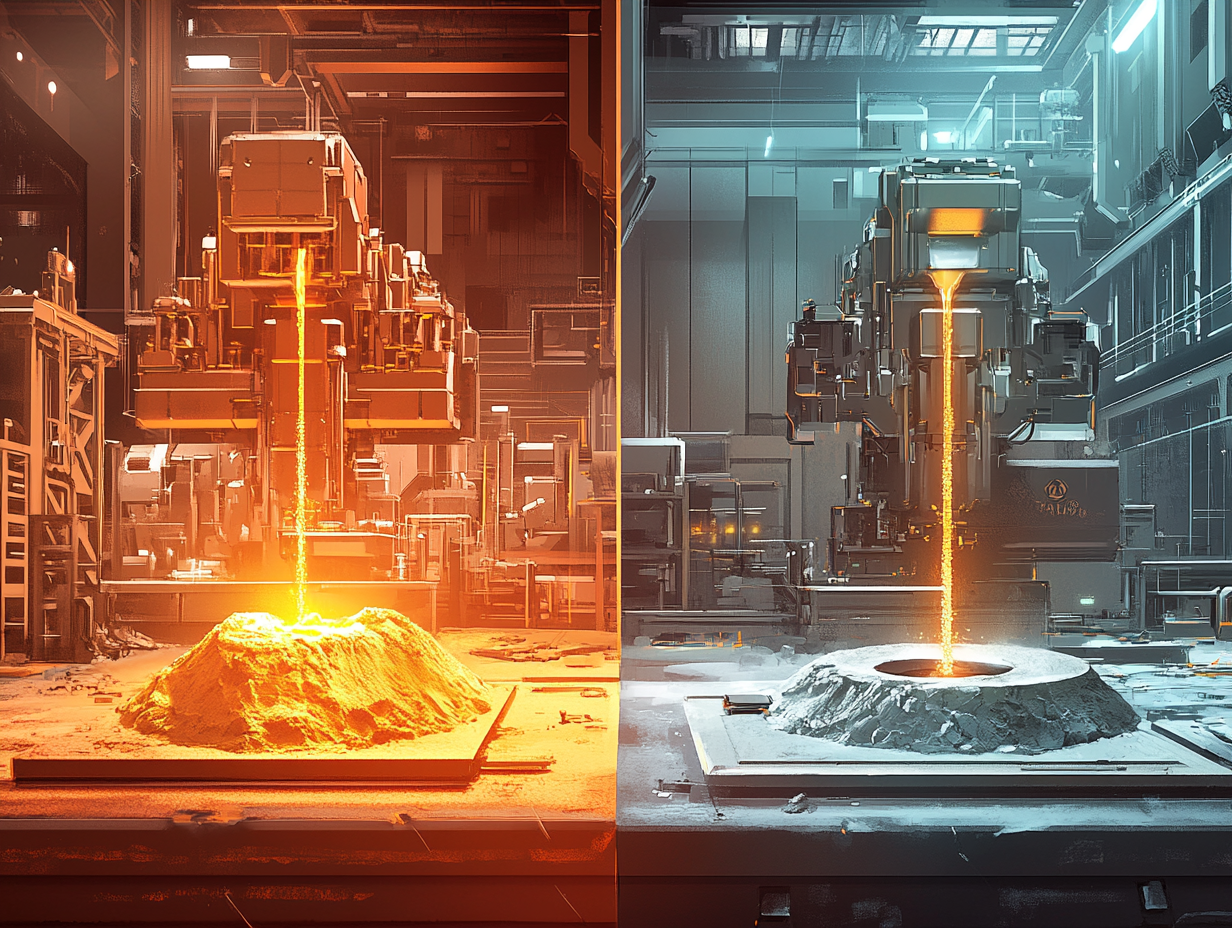

Materials used in casting significantly influence the durability, performance, and cost-effectiveness of the final product. Choosing the right material not only enhances quality but also improves production efficiency.

Casting processes are integral to modern manufacturing, offering tailored techniques for various applications. Selecting the right casting method is crucial for reducing costs, accelerating production, and achieving high-quality outcomes.

In casting processes, material utilization is a critical factor that directly impacts product quality and cost efficiency. Optimizing material usage not only streamlines production but also minimizes waste, leading to significant cost savings. Additionally, identifying and addressing potential defects early in the process enhances the durability and functionality of the final product.

n industrial manufacturing, every millimeter counts. Particularly in casting processes, tolerances and shrinkage calculations play a pivotal role in determining the quality and functionality of the final product. These technical details not only optimize production costs but also ensure a flawless product that meets customer expectations.