Casting processes are integral to modern manufacturing, offering tailored techniques for various applications. Selecting the right casting method is crucial for reducing costs, accelerating production, and achieving high-quality outcomes. Here are the most common casting techniques and their applications:

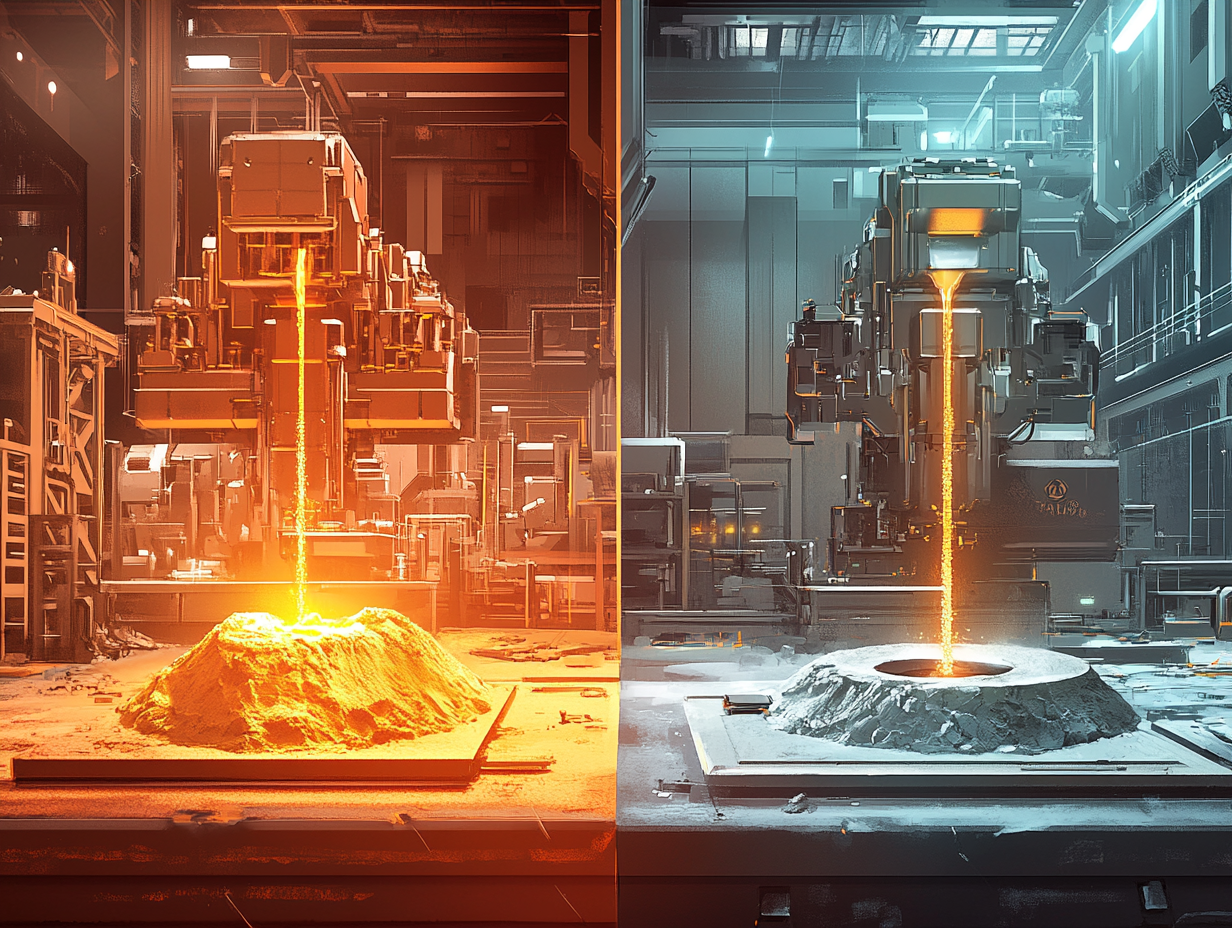

1. Manual Molding: Traditional and Flexible

Manual molding is ideal for small-scale production. Using sand or synthetic sand, this technique allows the creation of intricate and detailed parts, making it perfect for prototyping and low-volume orders.

- Advantages: Flexible design, low initial costs.

- Disadvantages: Slower production times.

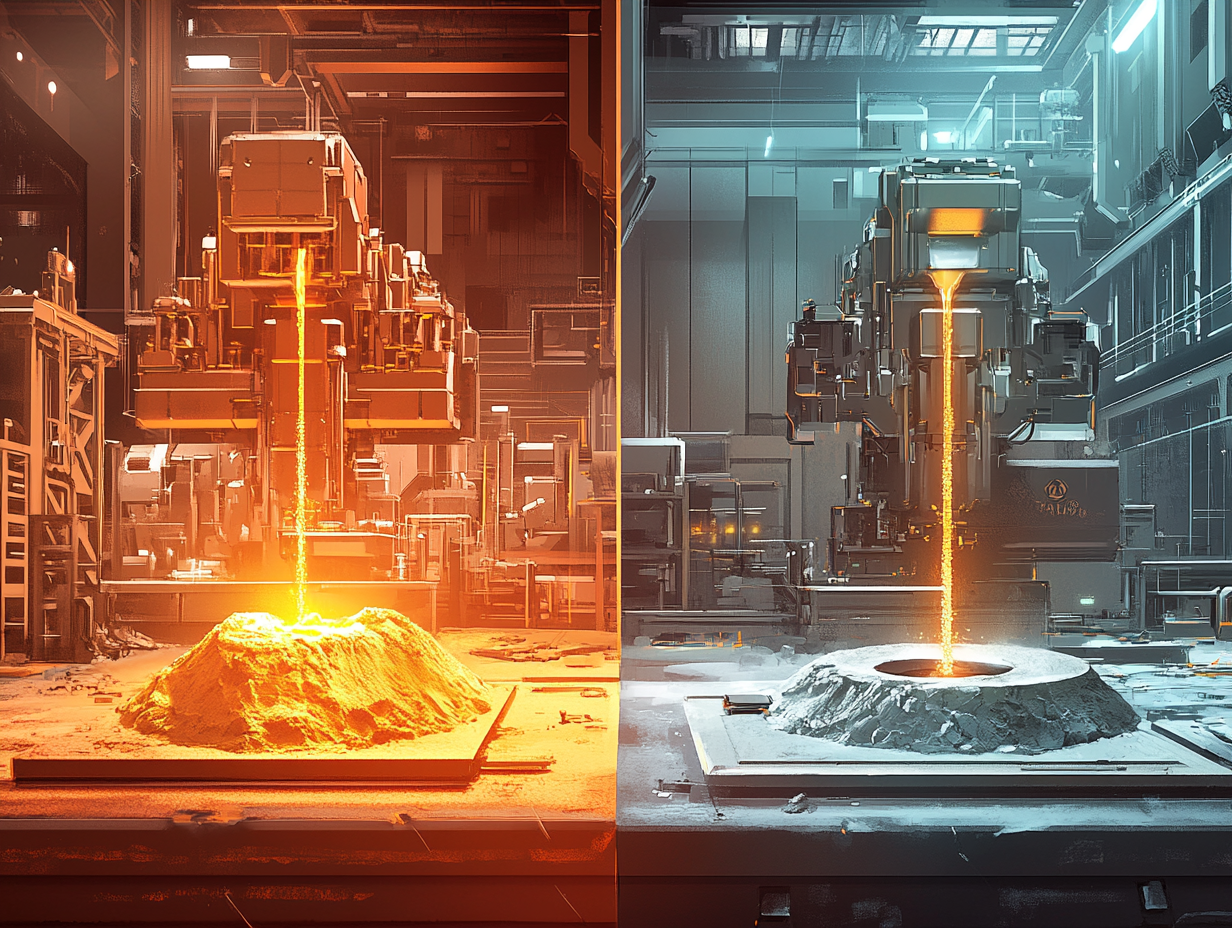

2. Machine Molding: Perfect for Mass Production

Machine molding suits high-volume manufacturing needs. Semi-automatic or fully automatic machines are used to produce parts requiring precise tolerances.

- Advantages: Fast production, low defect rates.

- Disadvantages: High initial investment.

3. Precision Casting: For Intricate and Detailed Parts

Precision casting is used when fine details and complex designs are required. It is common in industries such as jewelry, aerospace, and medical equipment.

- Advantages: High surface quality, minimal finishing required.

- Disadvantages: Higher costs.

4. High-Pressure Die Casting: Speed and Strength

This method is typically used for lightweight metals like aluminum and magnesium. Parts are cast under high pressure, making it ideal for industries like automotive, where durability and speed are paramount.

- Advantages: Suitable for mass production, high strength.

- Disadvantages: Limited material options.

Choosing the right casting technique optimizes production costs while enhancing product quality. Each method provides unique solutions tailored to different needs and production volumes. A project-specific analysis ensures businesses select the most efficient and effective approach.