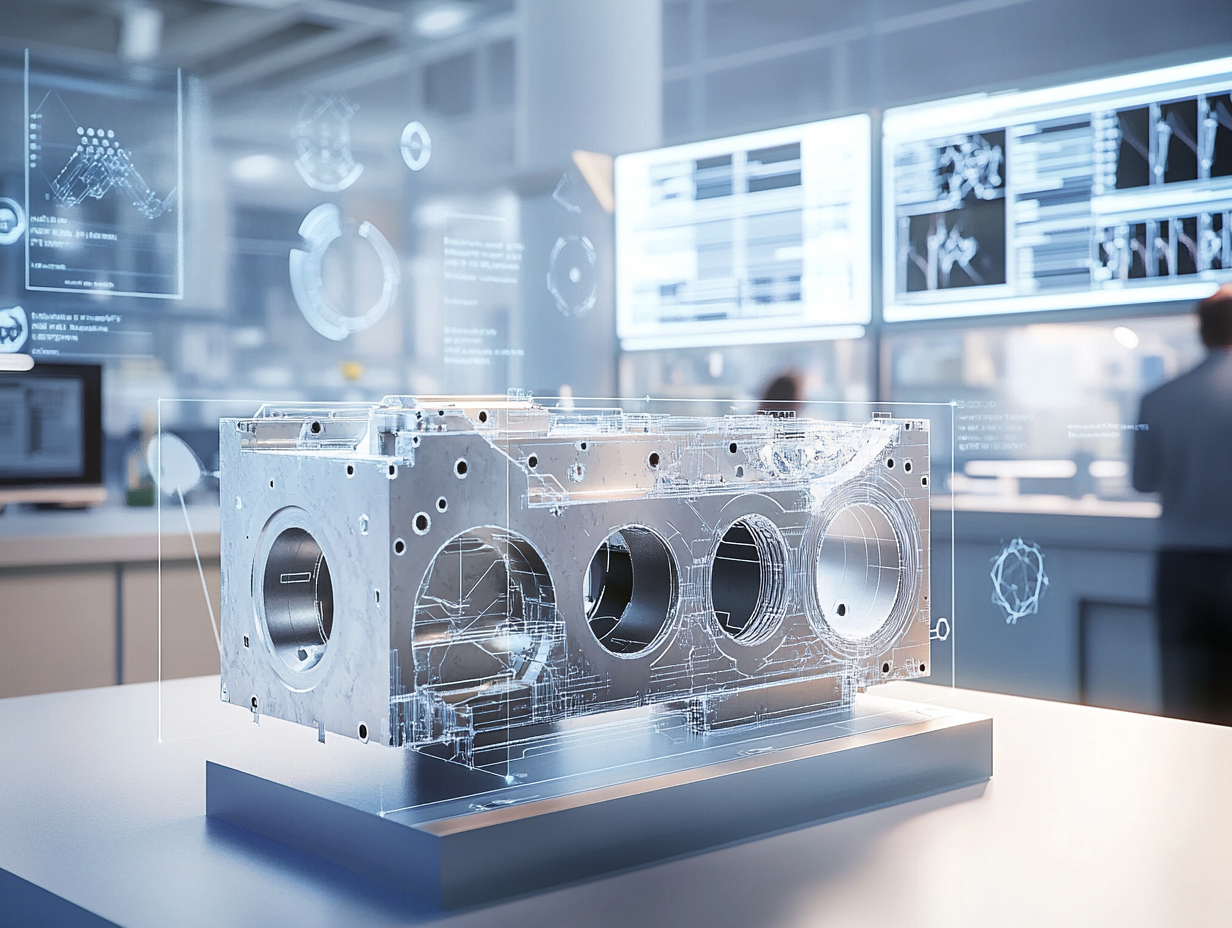

In industrial manufacturing, every millimeter counts. Particularly in casting processes, tolerances and shrinkage calculations play a pivotal role in determining the quality and functionality of the final product. These technical details not only optimize production costs but also ensure a flawless product that meets customer expectations.

The Importance of Tolerances

Casting tolerances define how closely a part’s actual dimensions align with the design specifications. These tolerances fall into two main categories: DTA (High Precision Tolerances) and DTB (Standard Tolerances).

- DTA: Ideal for high-tech applications that require minimal deviations.

- DTB: A more commonly used, cost-effective tolerance group for practical purposes.

Choosing the right tolerance group reduces error rates in production and achieves higher quality at lower costs.

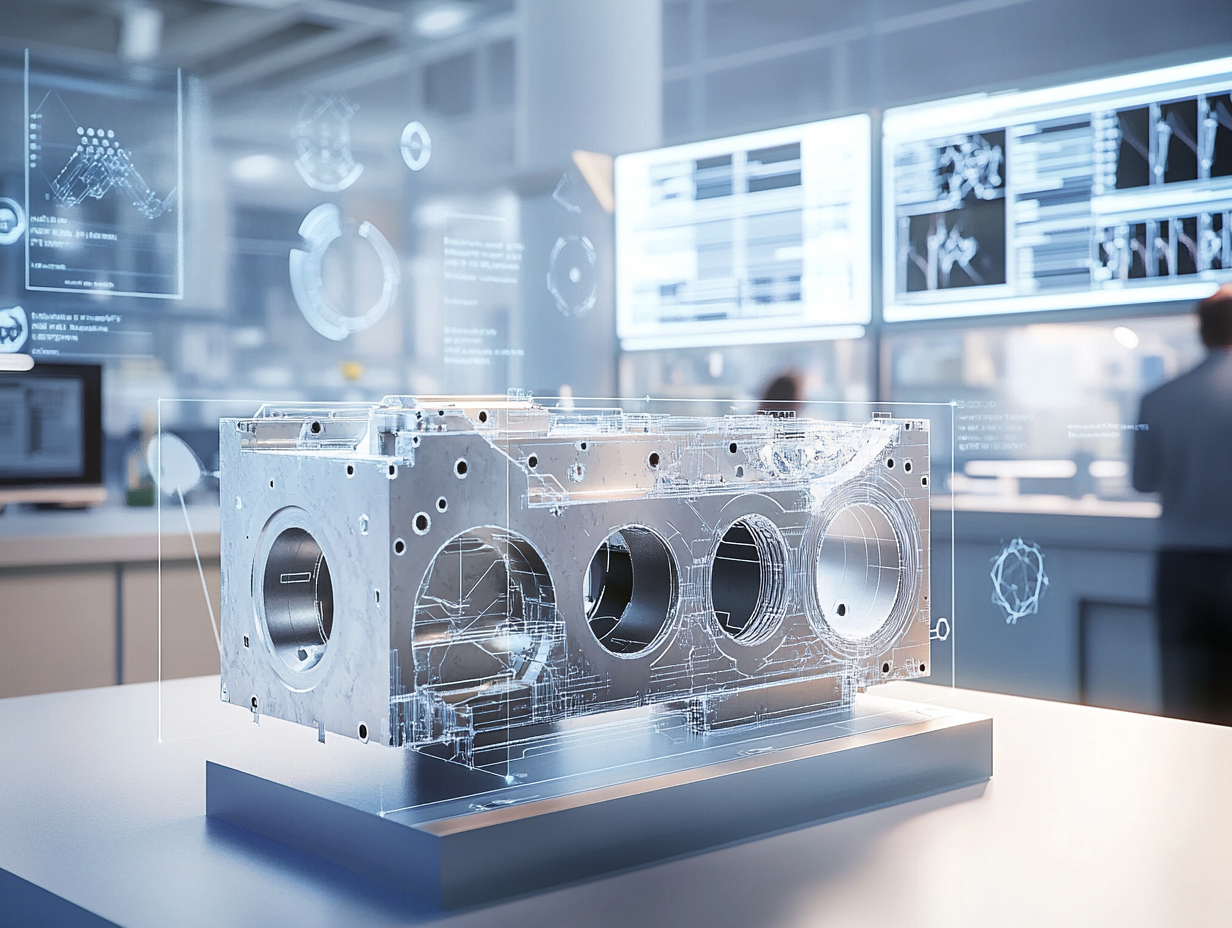

The Role of Shrinkage Calculations

During the casting process, material loses some volume as it transitions from liquid to solid state. This phenomenon, known as casting shrinkage, can cause deformations and dimensional inaccuracies if not properly accounted for.

- Liquid Shrinkage: Occurs when the material is in its molten state and is balanced through feeder systems.

- Solid Shrinkage: Happens during solidification and is mitigated by designing oversized patterns.

Collaborating with casting experts is essential to accurately calculate shrinkage rates and minimize material waste.

Standards and Global Compatibility

Standards like ISO, DIN, and TS ensure that tolerance and shrinkage calculations are globally consistent. Non-compliance with these standards can result in customer dissatisfaction and increased costs due to rework.

Conclusion

Casting tolerances and shrinkage calculations ensure precision and quality in industrial manufacturing. By implementing accurate calculations and adhering to international standards, companies can enhance their competitive edge and build lasting customer trust.