What Are Tundish Mechanisms?

Tundish mechanisms are specialized equipment used in the metal casting industry to control and safely transfer molten metal into molds. These mechanisms ensure precision and reliability at every stage of the casting process, thereby enhancing the quality of the final product. Tundish mechanisms play a crucial role, especially in the casting of metals such as steel, aluminum, and copper.

What Are They Used For?

Tundish mechanisms are used to transfer molten metal into molds during casting processes. These mechanisms ensure that the metal flows into the molds in the correct amount and evenly. This ensures the accuracy and consistency of the casting process. These devices are essential for maintaining the quality of the metal and optimizing the casting process.

Why Are They Important?

The importance of tundish mechanisms lies in their ability to enhance the quality and efficiency of the casting process.

- High-Quality Products: Ensuring that molten metal flows into the mold smoothly and in a controlled manner results in homogeneous and high-quality products.

- Waste Reduction: Controlled flow minimizes metal waste and reduces costs.

- Operational Efficiency: Speeding up the production process and reducing errors increases overall efficiency.

- Safety: In high-temperature casting processes, tundish mechanisms enhance safety and prevent workplace accidents.

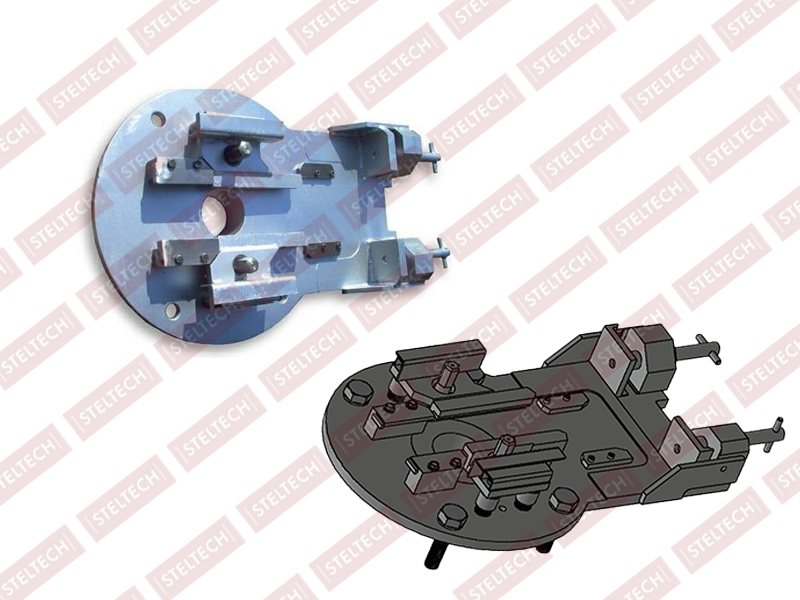

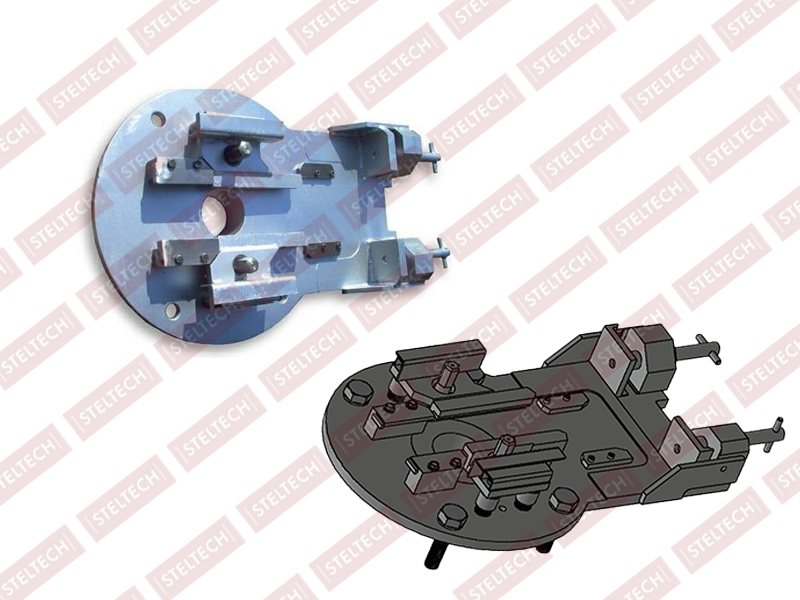

Our Expertise and Professionalism

Our company has years of experience in the design and production of tundish mechanisms, providing solutions that meet the highest engineering standards. The tundish mechanism shown in the image is the result of the dedicated efforts of our engineers and technicians. Every detail has been meticulously designed and manufactured to ensure durability and precision.

Advantages of Our Tundish Mechanisms

- Durability: Long-lasting use with high-quality materials and superior engineering.

- Precision: Ensures that molten metal flows into molds accurately and evenly.

- Ease of Use: Ergonomic design and ease of use provide comfort for operators.

- Low Maintenance: Requires minimal maintenance, reducing operational costs.

Our tundish mechanisms can make a significant difference in your production processes. For more information and to learn about our customized solutions for your business, please contact us. We would be delighted to work with you, drawing on our expertise and professionalism in this field.

CNM tundish mechanisms offer ideal solutions for businesses aiming for excellence in the metal casting industry. Trust us to enhance your business’s efficiency and production quality.