In the world of mining machinery and structural engineering, components rarely face a single type of stress. Instead, they often experience combined stresses a mix of bending, torsion, shear, and axial loads. To ensure these parts don’t fail under complex loading, engineers use the Von Mises Criterion to evaluate overall material strength.

This article walks through how to apply the Von Mises stress equation for real-world mining components and why it’s essential for modern design verification.

1. What Are Combined Stresses?

Combined stresses occur when multiple types of loading act on a component simultaneously. Common examples in mining include:

-

Bending + torsion (in shafts)

-

Axial load + shear (in support columns)

-

Internal pressure + bending (in pipes or hollow arms)

Without evaluating their combined effect, design risks increase — leading to fatigue, cracking, or sudden failure.

2. The Von Mises Stress Formula

The Von Mises Criterion transforms multiple stress components into an equivalent uniaxial stress, which can be compared directly to the material’s yield strength.

For combined bending and torsion:

σeq=σb2+3τ2σ_{eq} = \sqrt{σ_b^2 + 3τ^2}

Where:

-

σbσ_b = Bending stress

-

ττ = Shear stress from torsion

✅ If σeq<σyieldσ_{eq} < σ_{yield}, the design is considered safe under static conditions.

3. Why Use Von Mises in Mining Design?

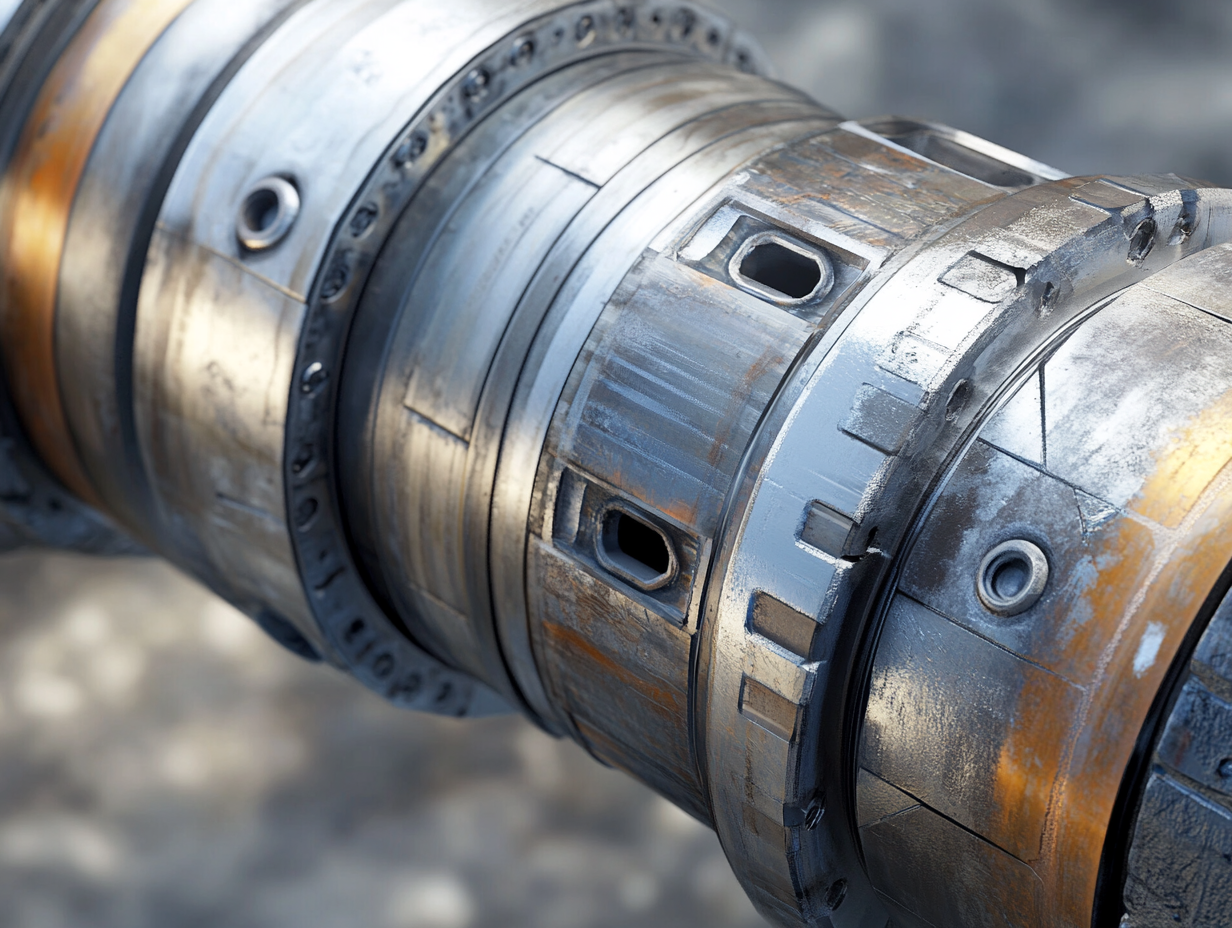

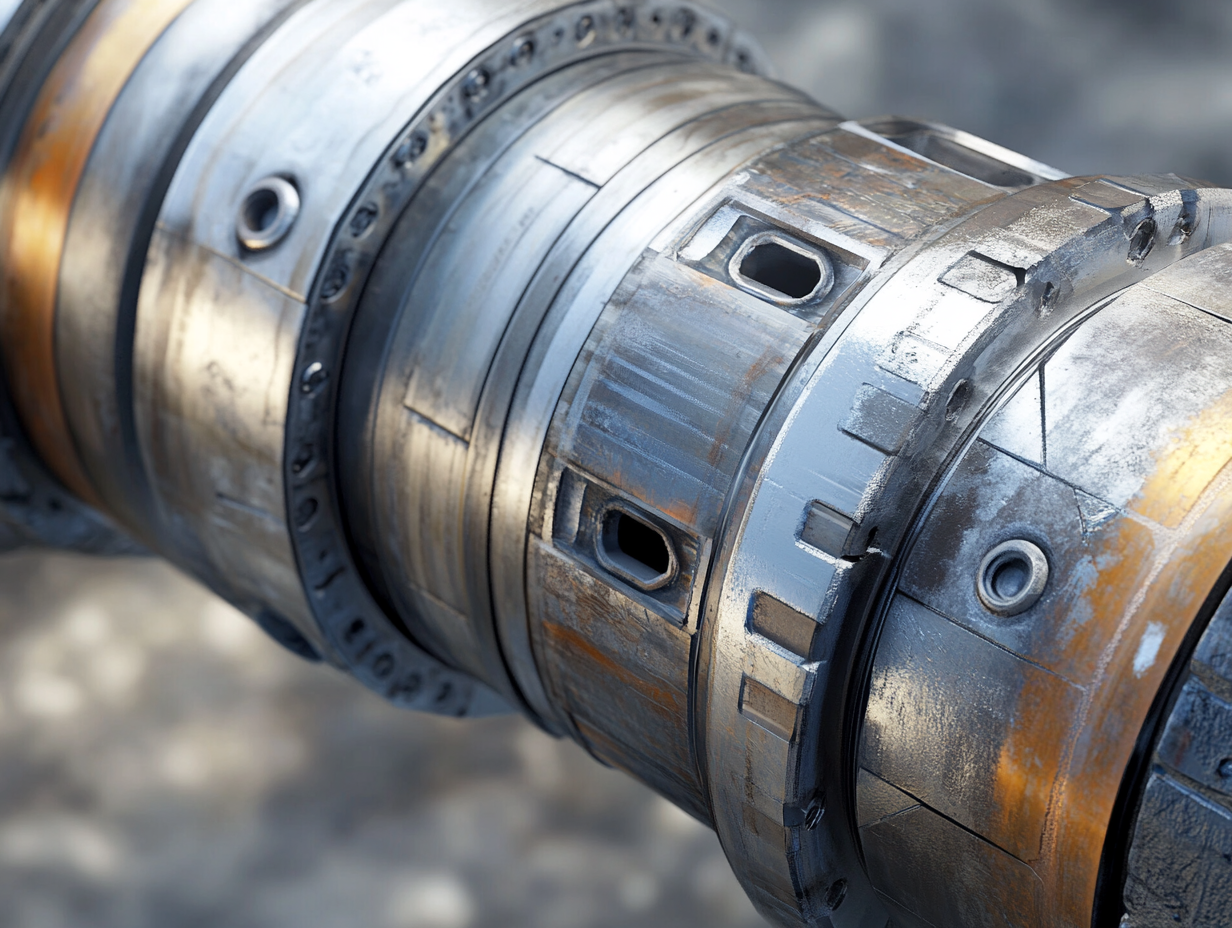

Mining machinery like drive shafts, boom arms, crushers, and pulleys are under constant multiaxial loading:

-

Variable torque from motors

-

Dynamic bending from moving loads

-

Vibration-induced shear stress

Using Von Mises ensures safety even when forces are unpredictable and directions shift frequently.

4. Real-World Example: Mining Conveyor Shaft

-

Shaft sees:

-

M=1200 NmM = 1200 \, \text{Nm}

-

T=800 NmT = 800 \, \text{Nm}

-

Diameter d=60 mmd = 60 \, \text{mm}

-

Calculate bending and torsional stress:

σb=32Mπd3,τ=16Tπd3σ_b = \frac{32M}{πd^3}, \quad τ = \frac{16T}{πd^3}

Then, calculate:

σeq=σb2+3τ2σ_{eq} = \sqrt{σ_b^2 + 3τ^2}

Compare σeqσ_{eq} to yield strength of material (e.g., 355 MPa for S355 steel). If within safe limits, proceed. If not, increase diameter or change material.

5. When to Use Full 3D Stress Form

For complex 3D stress states (e.g., FEM analysis):

σvm=12[(σ1−σ2)2+(σ2−σ3)2+(σ3−σ1)2]σ_{vm} = \sqrt{\frac{1}{2}[(σ_1 – σ_2)^2 + (σ_2 – σ_3)^2 + (σ_3 – σ_1)^2]}

But for cylindrical and symmetrical shafts, the simpler version is typically sufficient for field calculations.

6. Design Tips Using Von Mises

✔️ Always evaluate critical zones where multiple forces act

✔️ Use FEM tools for complex geometries

✔️ Monitor components under fatigue with safety factors of 2.0+

✔️ Perform Von Mises check in both static and dynamic loading scenarios

The Von Mises Criterion is a fundamental tool in mining equipment design, allowing engineers to confidently verify whether components can withstand the complexity of real-world stress combinations. By incorporating it early in the design stage, you protect not only your equipment — but also your team, your timelines, and your bottom line.