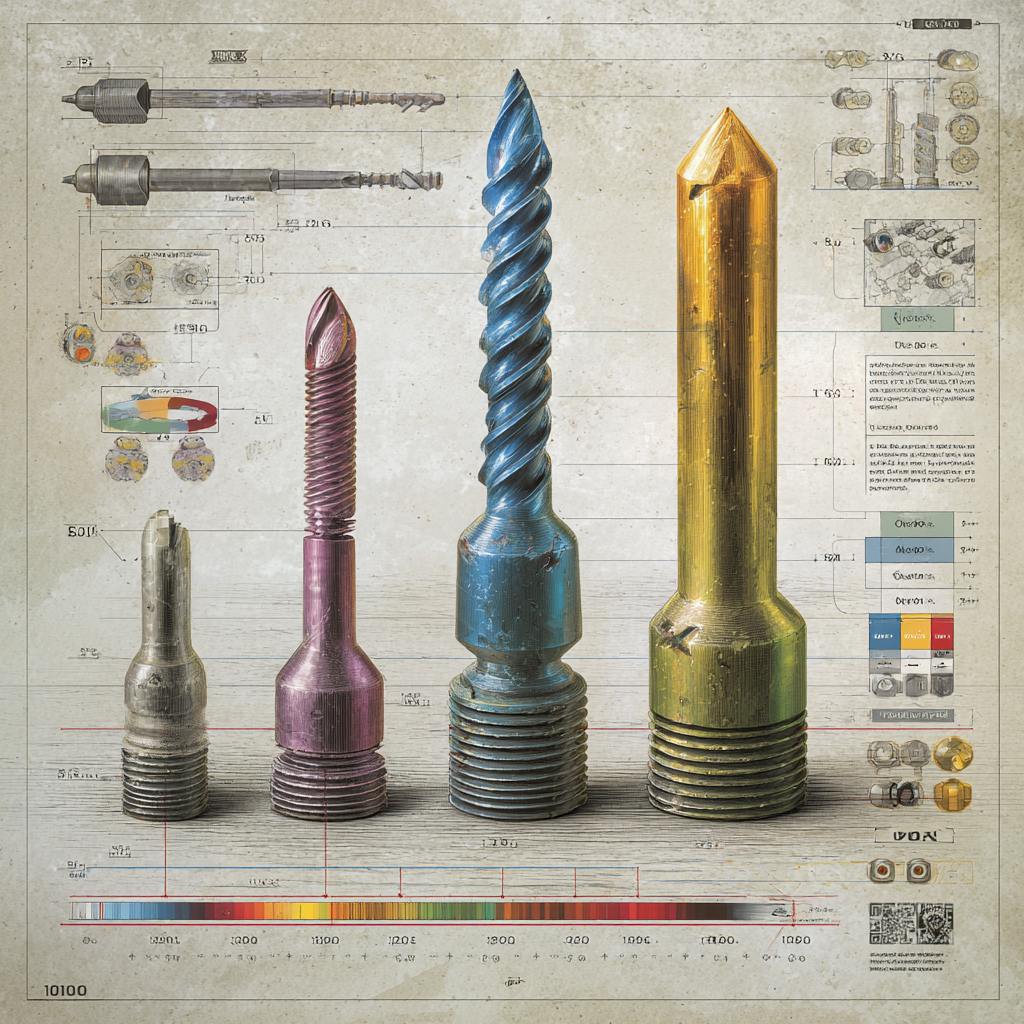

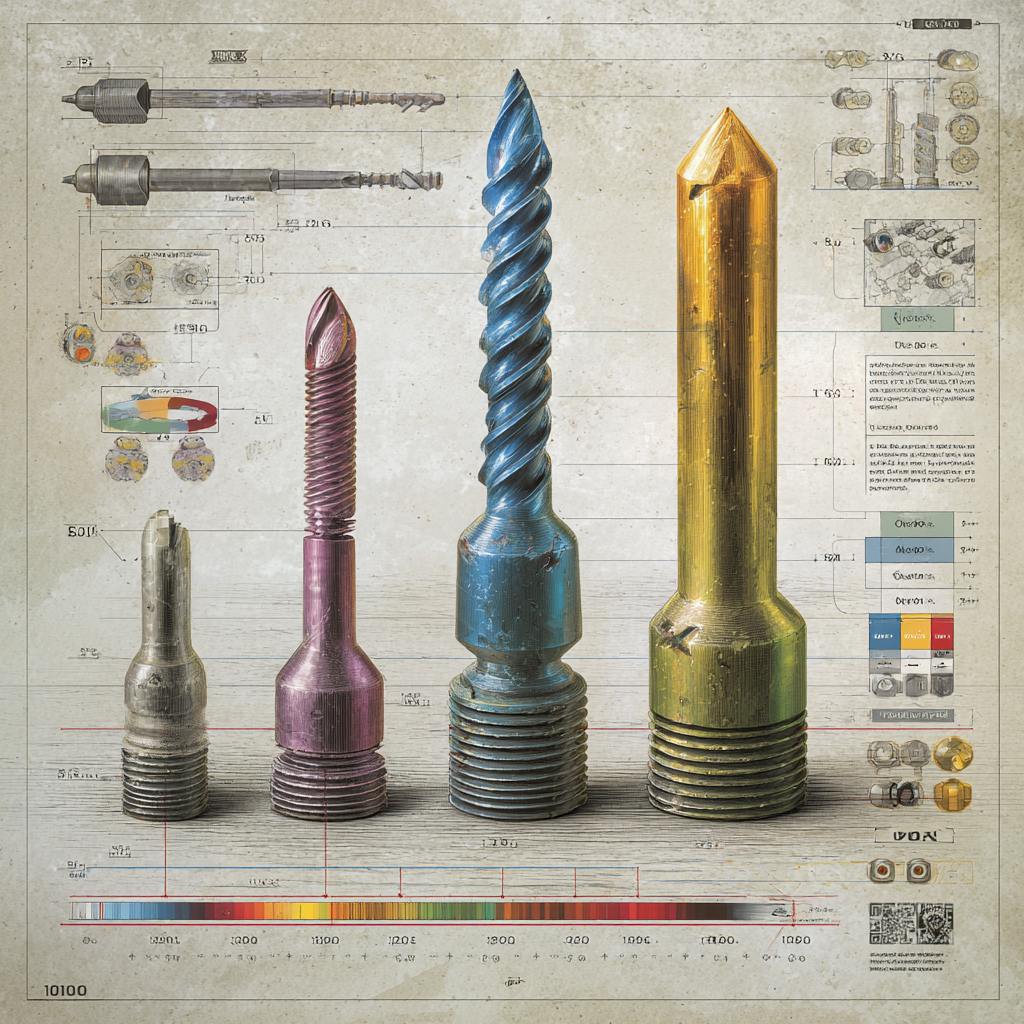

Drills may create holes, but for true precision and durability, countersinks and center drills take the stage. These tools refine, guide, and prepare holes so that fasteners fit perfectly and machining remains accurate.

Countersinks (DIN 334, 335, 347)

A countersink creates a conical recess at the top of a hole. This allows a flat-head screw to sit flush with the surface. DIN standards define different angles — 60°, 90°, 120° — depending on the screw type.

💡 Analogy: Like carving a little seat for the screw head to rest in. Without this, the screw would stick out and create uneven surfaces.

Industrial Use:

-

Flush screw installation in machine housings

-

Chamfering edges for safety and smoother assembly

Center Drills (DIN 333)

Center drills are short, strong tools that guide other drills. They create a small starting point to prevent long drills from “wandering.”

💡 Analogy: Like a pioneer marking the land before the settlers arrive. The center drill makes sure the main drill follows the right path.

Industrial Use:

-

Starting holes for lathes

-

Precision positioning in machining

-

Reducing tool breakage in deep drilling

Stub and Jobber Drills (DIN 1897, 338)

While countersinks and center drills prepare the hole, stub and jobber drills carry out most of the work.

-

Stub drills (DIN 1897): Short and rigid for accuracy.

-

Jobber drills (DIN 338): Standard all-purpose drills used in almost every shop.

Why They Matter

✔️ Ensure screws sit flush and safe

✔️ Prevent drill wander for accurate machining

✔️ Improve durability of holes and tools

✔️ Essential in both everyday DIY and heavy industry

Countersinks and center drills may seem minor, but they are key to precision and safety in machining. Backed by DIN standards, they ensure every hole starts and finishes exactly as intended.