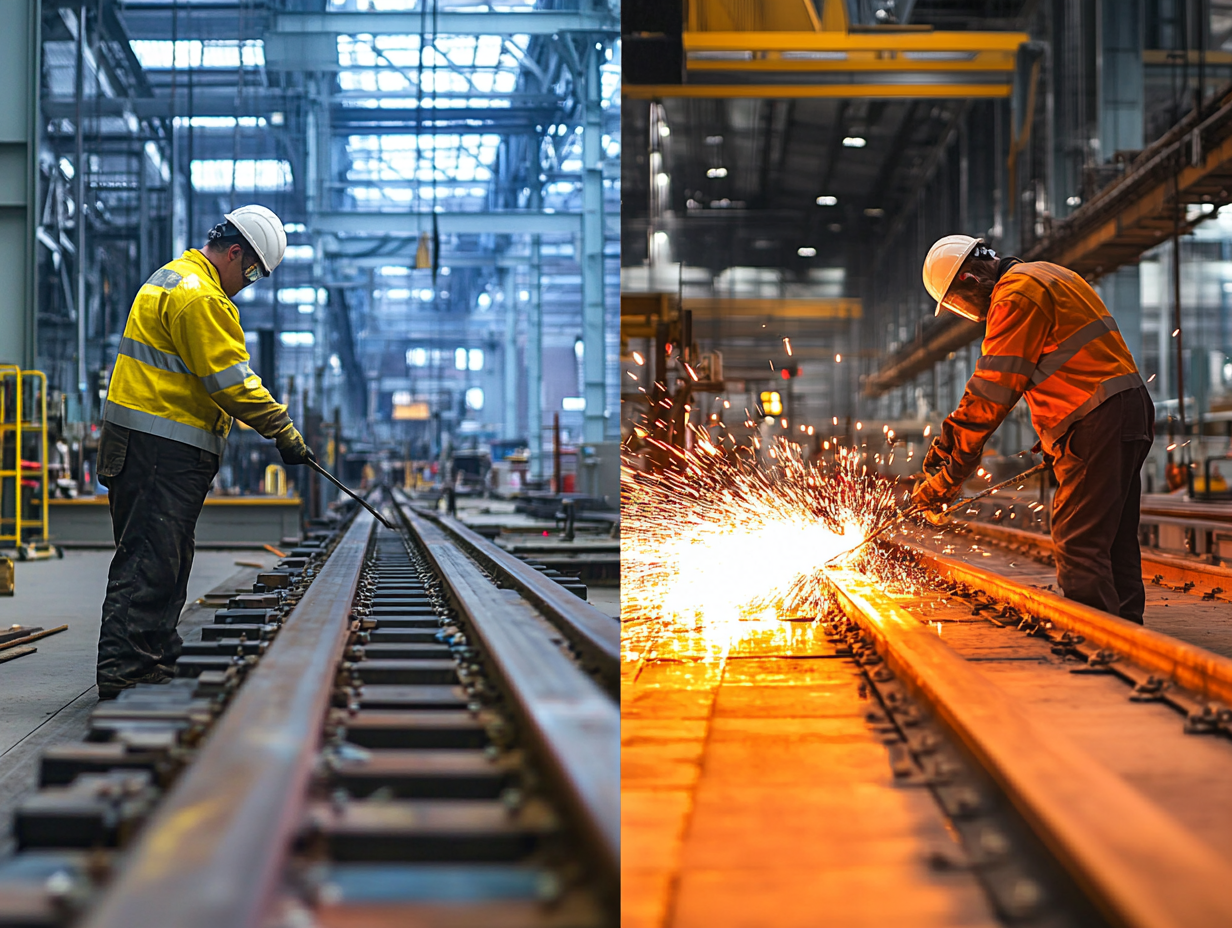

✔ Preventive Maintenance – Regular inspections and early interventions to prevent failures before they happen.

✔ Reactive Maintenance – Repairs and replacements performed only after a failure has occurred.

2. Advantages of Preventive Maintenance

✔ Reduces Unplanned Downtime

- Identifies wear patterns and misalignments early, preventing unexpected breakdowns.

✔ Extends Rail Lifespan

- Ensures consistent rail alignment and load distribution, reducing premature wear.

✔ Minimizes Repair Costs

- Small interventions prevent major failures that require expensive overhauls.

✔ Enhances Operational Safety

- Prevents track misalignment and structural failure, reducing accident risks.

3. Risks of Reactive Maintenance

✖ Increased Downtime

- Waiting for a failure leads to longer operational disruptions.

✖ Higher Repair Costs

- Emergency repairs and part replacements are more expensive.

✖ Accelerated Rail Wear

- Neglected rail defects lead to faster surface degradation and misalignment.

✖ Higher Safety Risks

- Sudden failures increase the likelihood of crane accidents.

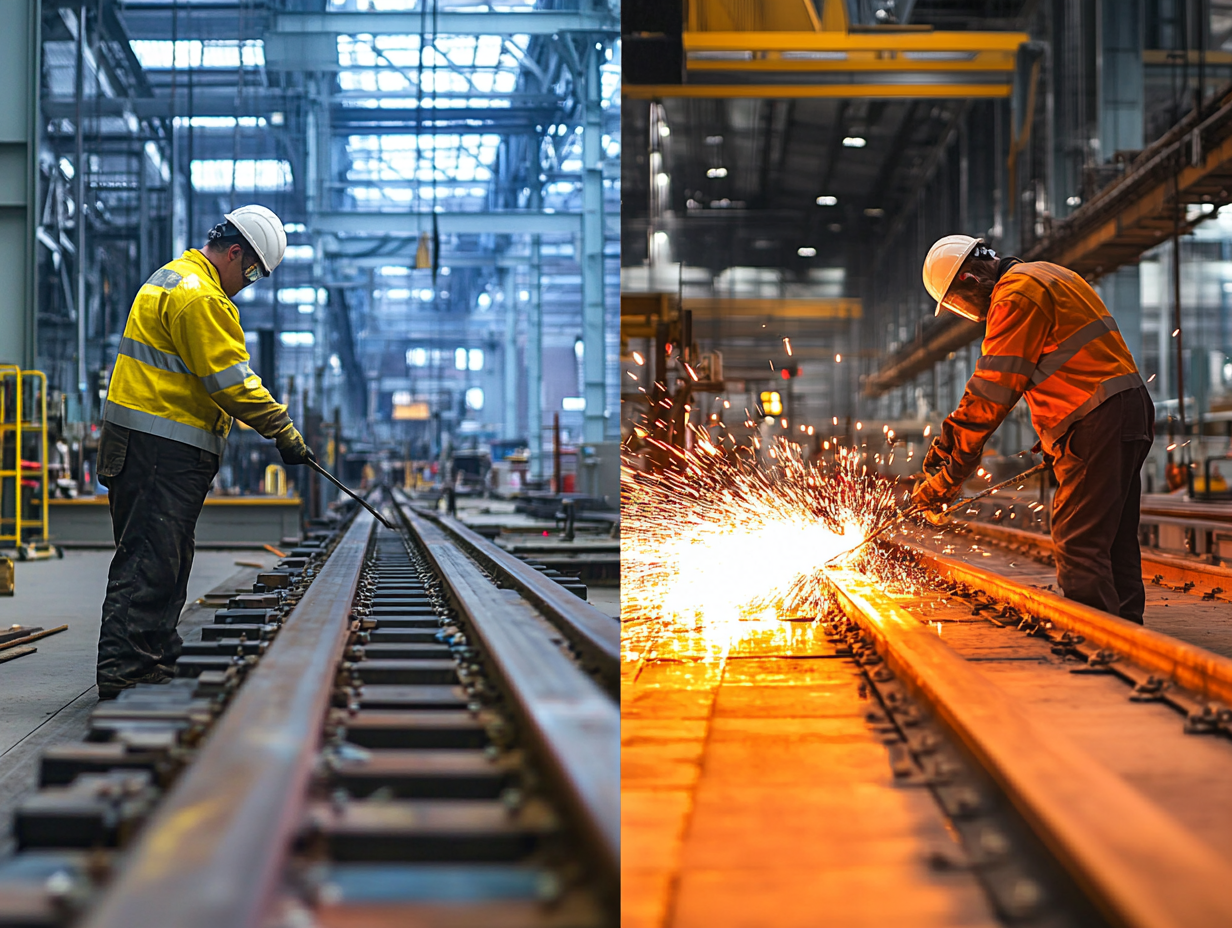

4. Key Preventive Maintenance Practices

✔ Routine Track Inspections

- Use laser-guided alignment tools to check rail straightness and surface wear.

- Conduct vibration and stress tests to detect fatigue-related weaknesses.

✔ Lubrication and Friction Management

- Apply protective coatings to prevent rust and reduce friction.

- Maintain optimal rolling resistance between crane wheels and rails.

✔ Structural Integrity Testing

- Perform ultrasonic and magnetic particle testing (MPT) to detect internal cracks.

- Inspect bolted and welded connections for potential loosening.

✔ Load and Performance Monitoring

- Implement real-time sensor technology to track force distribution and stress levels.

- Adjust crane speed and braking forces to minimize impact loads on rails.

5. Choosing the Right Maintenance Strategy

| Factor | Preventive Maintenance | Reactive Maintenance |

|---|---|---|

| Downtime Impact | Minimal | High |

| Cost Efficiency | Lower long-term cost | Higher emergency costs |

| Safety Level | High | Moderate to low |

| Rail Lifespan | Extended | Reduced |

| Recommended For | Heavy-duty and high-precision crane operations | Low-use or temporary crane installations |

- Implementing a preventive maintenance approach is the most cost-effective and safest solution for crane rail systems. Early inspections, proper lubrication, and real-time monitoring help extend rail lifespan, reduce downtime, and enhance overall operational efficiency.