Cold bending is a critical process that allows for precise shaping of metals at room temperature. Accurate dimensional calculations ensure the integrity, durability, and functionality of the final product. This article explores the essential aspects of material thickness, bending radius, and methods to optimize production quality in cold bending.

1. The Impact of Material Thickness on Bending

Material thickness significantly influences the bending radius and process feasibility.

- Thin Materials:

- Can handle smaller bending radii and require less force.

- Commonly used in lightweight applications like electronics casings.

- Thick Materials:

- Require larger bending radii to avoid cracking.

- Often used in structural applications like beams and chassis components.

2. Bending Radius Calculations

Formula for Minimum Bending Radius:

Rmin=k⋅tR_{\text{min}} = k \cdot t

- Rmin: Minimum bending radius.

- k: Coefficient for material elasticity.

- t: Material thickness.

Example Calculation:

For 5 mm thick high-carbon steel:

Rmin=1.5⋅5=7.5 mm.R_{\text{min}} = 1.5 \cdot 5 = 7.5 \, \text{mm}.

3. Preventing Cracks During Bending

To minimize cracking risks:

- Use bending radii appropriate for the material’s tensile strength.

- Align the bending direction with the material grain structure.

- For rigid materials, consider hot bending as an alternative.

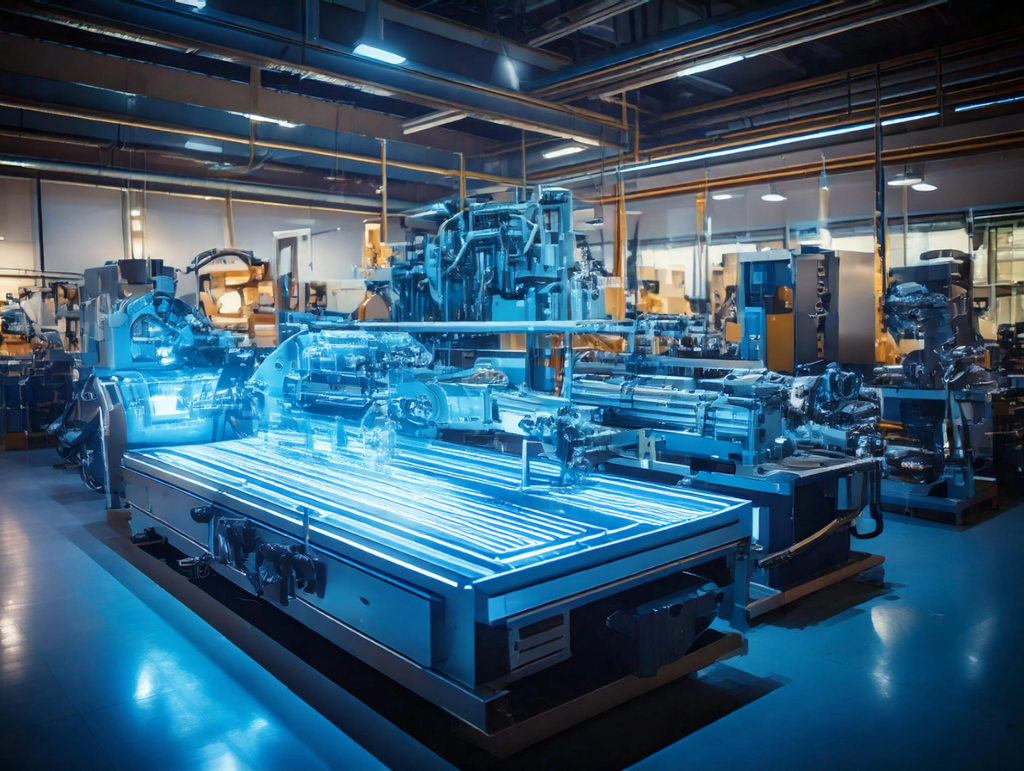

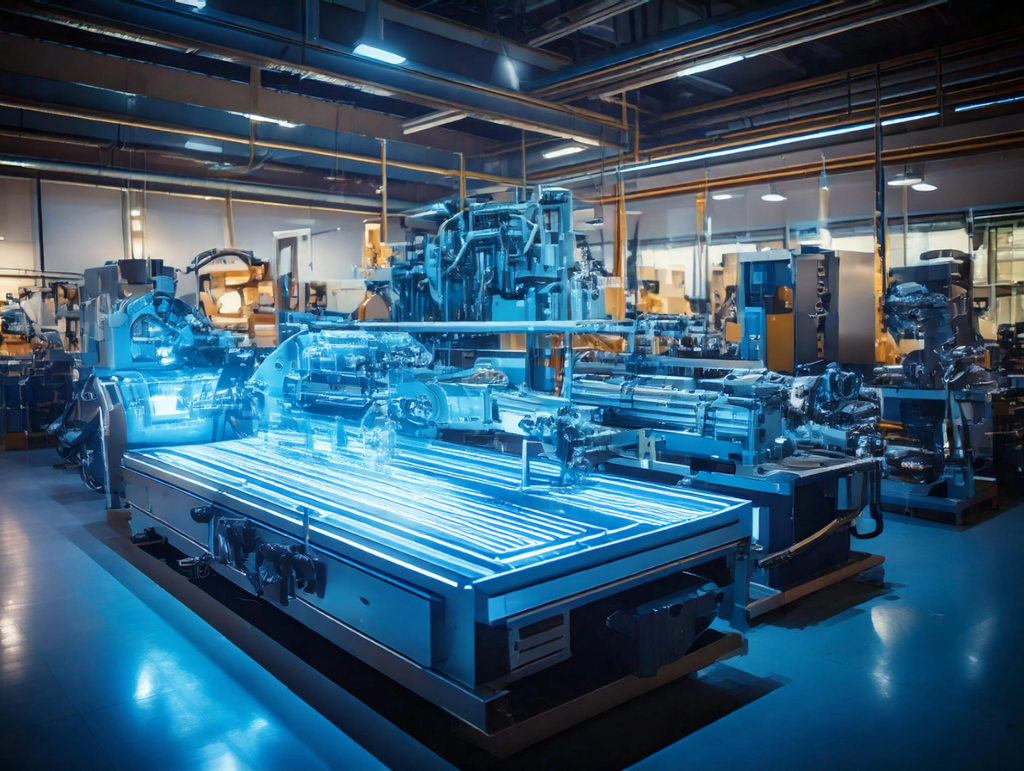

4. Applications Across Industries

Automotive:

- Enables precision bending for chassis and panels.

- Ensures lightweight, durable designs.

Construction:

- Shapes structural beams and pipes for enhanced safety.

Aerospace:

- Produces lightweight yet durable components for high-performance applications.

- Dimensional accuracy in cold bending is essential for manufacturing success. Precise calculations reduce costs, minimize waste, and produce high-quality components tailored to industrial needs.