Many rotating shafts in mining and industrial equipment run on journal bearings — also known as plain bearings. Unlike ball bearings, which use rolling elements, journal bearings rely on sliding contact between the shaft and bearing surface.

They are strong, simple, and cost-effective, but they face two constant challenges: friction and wear.

1. What Is a Journal Bearing?

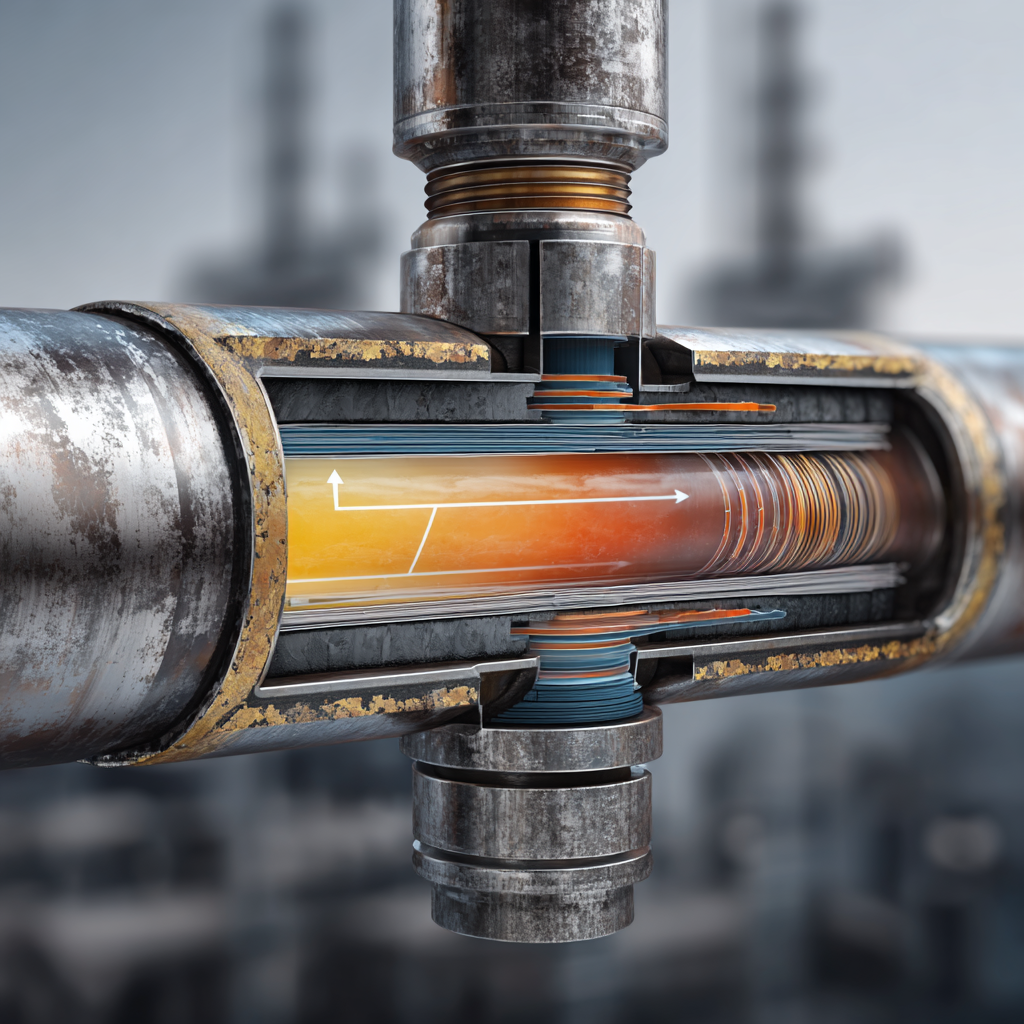

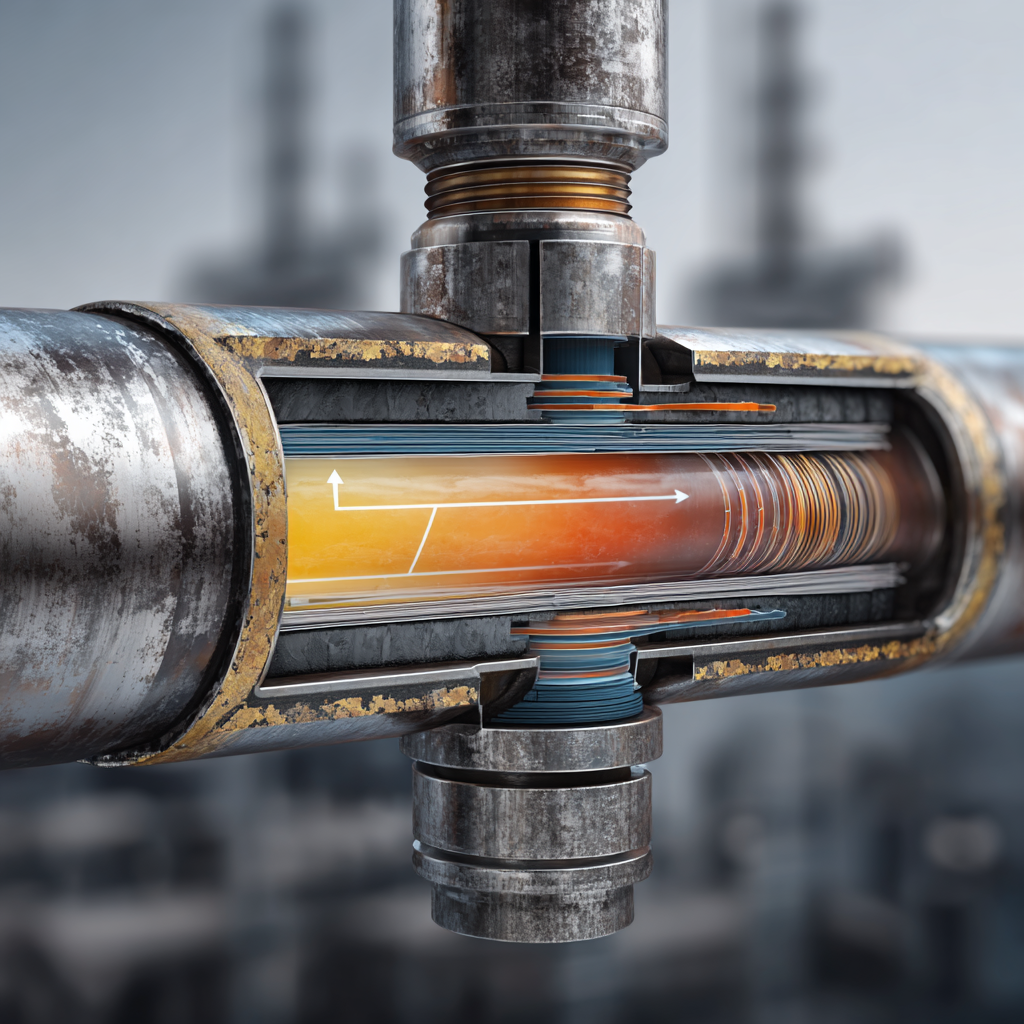

A journal bearing is basically a metal sleeve that supports a rotating shaft.

-

The shaft (journal) spins inside the bearing.

-

A thin film of lubrication separates the surfaces.

-

The bearing must carry heavy loads without letting the shaft touch the housing.

🛠️ Common in:

-

Conveyor systems

-

Crushers

-

Hoist machines

-

Large electric motors

2. Friction in Journal Bearings

Without lubrication, metal-to-metal contact would cause huge friction.

But with proper oil film:

-

The shaft “floats” on the lubricant

-

Friction drops dramatically

-

Energy losses are minimized

Types of friction here:

-

Boundary friction – at start/stop, when lubrication film is thin

-

Hydrodynamic friction – when a full film of oil separates shaft and bearing

3. Wear Mechanisms

Even with lubrication, bearings wear over time:

-

Adhesive wear: small surface particles transfer between shaft and bearing

-

Abrasive wear: hard particles in lubricant scratch surfaces

-

Fatigue wear: repeated stress causes surface cracks

If not controlled, wear can lead to:

❌ Shaft misalignment

❌ Vibration and noise

❌ Bearing seizure

4. Real-World Example: Mining Conveyor Shaft

A conveyor shaft supported by journal bearings runs 24/7.

-

If lubrication is poor, the bearing heats up.

-

Surface roughness increases → more friction.

-

Eventually, the shaft may seize, stopping the conveyor.

Regular lubrication and inspection prevent costly downtime.

5. How Engineers Reduce Friction and Wear

✔️ Use proper lubrication systems (oil bath, circulating oil)

✔️ Select bearing materials with low friction (bronze, Babbitt alloys)

✔️ Add grooves to distribute lubricant evenly

✔️ Monitor temperature and vibration for early fault detection

Journal bearings are simple yet critical components in mining machines. By controlling friction and wear with the right lubrication and design, engineers keep equipment running smoothly and extend its service life.