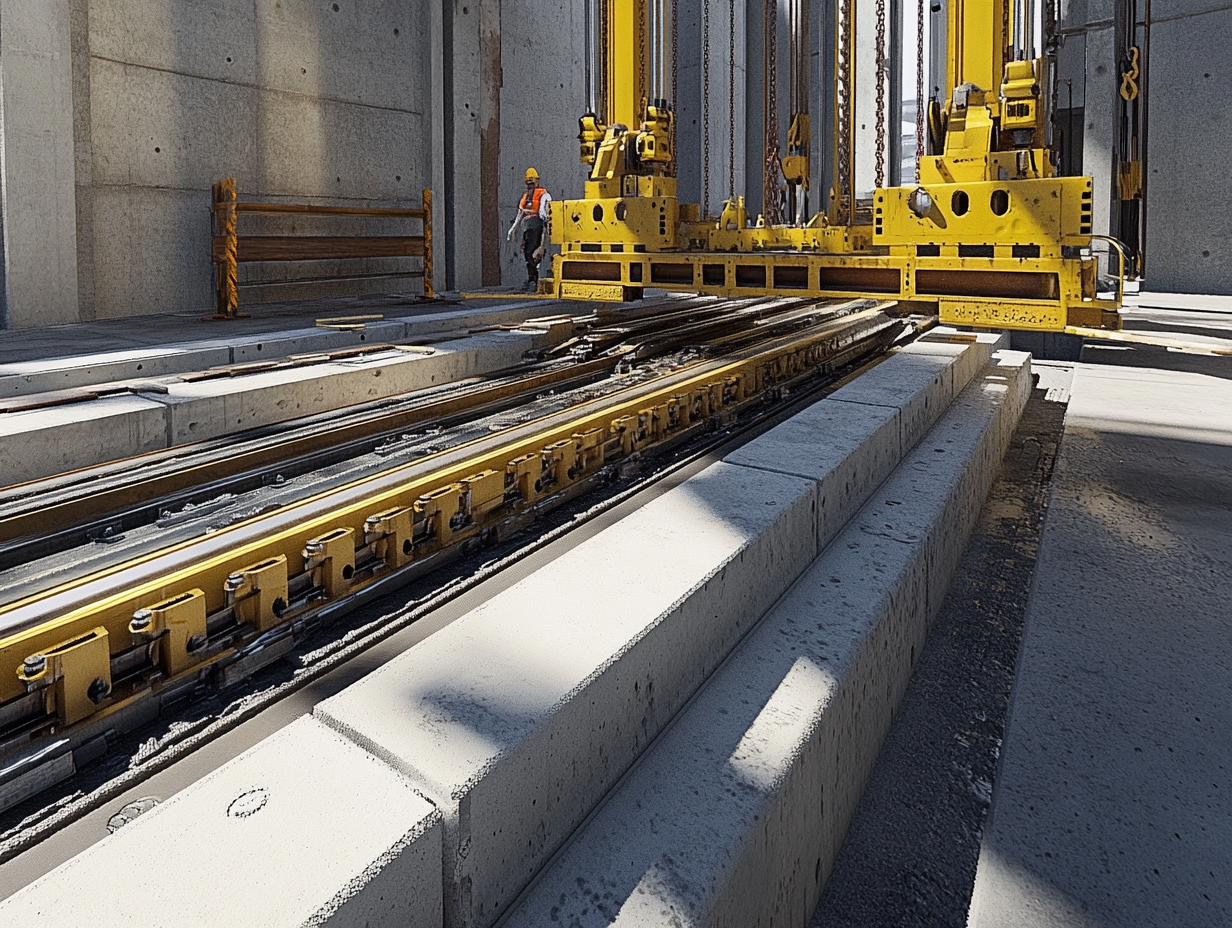

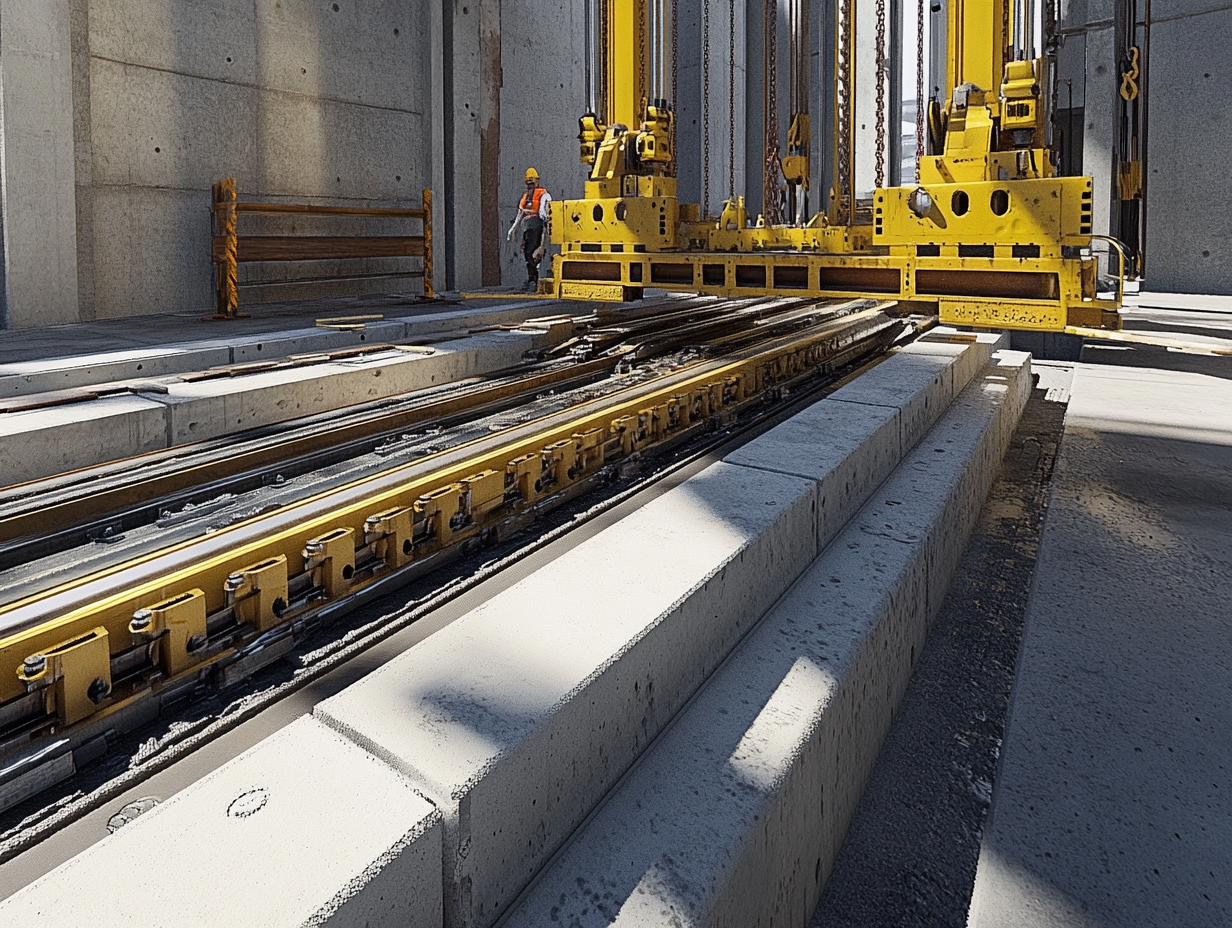

Crane tracks are engineering marvels designed to safely transport heavy loads. However, the reliability and durability of these systems depend heavily on the materials used and the design choices made. In this blog, we’ll explore the essential materials and various design options for crane tracks.

1. Materials Used in Crane Tracks

a) Steel Materials:

- Hot-Rolled Steel: Durable and cost-effective for crane rails.

- Alloy Steel: Suitable for higher load capacities.

b) Concrete Materials:

- Commonly used in support structures for crane tracks.

- Provides resistance to vibration and impact loads.

c) Lamels and Padding Systems:

- Steel lamels or elastic padding materials are used to prevent rail deformation.

2. Design Options for Crane Tracks

a) Single-Girder and Double-Girder Systems:

- Single-Girder Systems: Ideal for lighter loads and shorter tracks.

- Double-Girder Systems: Used for heavier loads and longer distances.

b) Open and Closed Rail Systems:

- Open Rail Systems: Offer easy maintenance and installation.

- Closed Rail Systems: Provide better protection against external factors.

c) Crane Rail Profiles:

- DIN 536 A and DIN 536 F profiles are selected based on load capacity requirements.

3. Advantages of the Right Material and Design Choices

a) Longer Lifespan:

- Durable materials prevent wear and deformation of the system.

b) Increased Safety:

- Proper design ensures balanced crane movements and prevents accidents.

c) Easier Maintenance:

- Suitable material and design choices simplify maintenance processes and reduce costs.

4. Key Considerations for Crane Track Design

a) Load Capacity:

- Materials and designs should match the maximum load requirements.

b) Environmental Conditions:

- Corrosion-resistant materials should be used for outdoor systems.

c) Vibration Control:

- Elastic padding materials can reduce wear caused by vibrations.

- Choosing the right materials and design for crane tracks ensures both durability and safety. These decisions are critical for optimizing production processes and reducing operational costs.