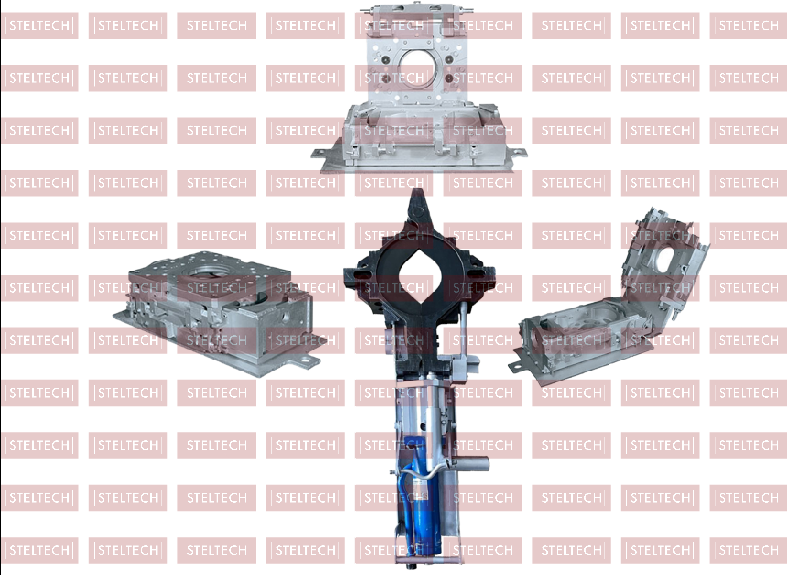

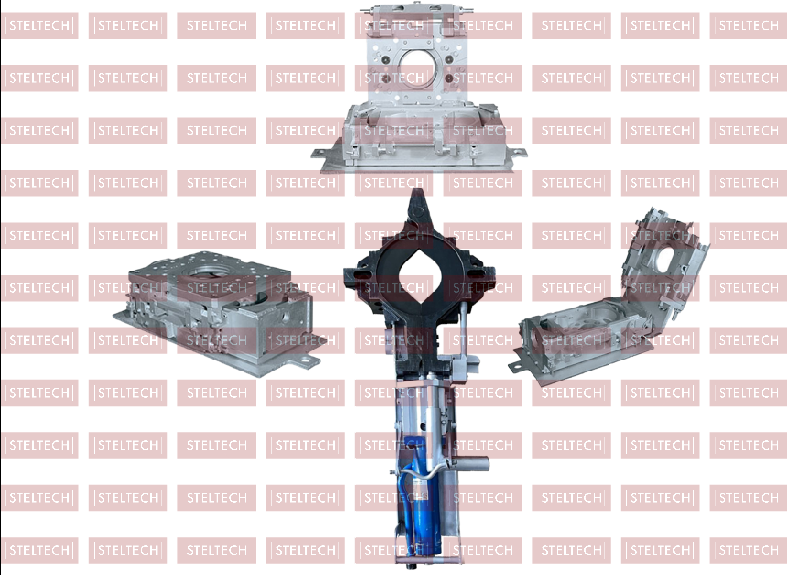

In continuous casting, the tundish is more than a reservoir — it is the first refinery that determines final steel quality. At Steltech Makina, we design tundish systems that optimize flow, reduce turbulence, and ensure cleaner metal delivery to the mold. Modern flow-control engineering can significantly reduce inclusions, stabilize temperature, and enhance casting performance across every strand.

Why Flow Optimization Matters

Inside the tundish, molten steel must transition smoothly from the ladle to the mold. Any uncontrolled turbulence creates:

-

Entrapped slag

-

Non-metallic inclusions

-

Temperature fluctuations

-

Uneven strand performance

Flow design is the key factor that transforms the tundish from a simple container into a precision metallurgical reactor.

Modern Flow-Control Devices

Steltech engineers use advanced CFD simulations and on-site performance data to select and configure devices that stabilize steel flow:

1. Dams and Weirs

These barriers channel steel movement, slowing turbulence and increasing residence time.

They help inclusions float upward toward the slag layer instead of entering the mold.

2. Baffles and Turbulence Stoppers

These reduce the kinetic energy of incoming steel, preventing violent surface agitation that disrupts the slag-metal interface.

3. Impact Pads

Placed directly under the ladle shroud, impact pads cushion the steel stream, reducing erosion of refractory surfaces and improving flow uniformity.

4. Subflux Turbulence Control Designs

New concepts such as oval pads, multi-chamber systems, and bottom-flow channels provide more predictable steel movement, especially in multi-strand tundishes.

Temperature Stability Through Flow Management

Uniform flow ensures uniform temperature.

Steltech tundish systems integrate:

-

Multi-point thermocouples

-

Optimized refractory insulation

-

Balanced strand distribution

This ensures each strand receives steel with consistent heat, improving casting speed and reducing defects like breakouts and shell thinning.

Cleaner Steel, Higher Productivity

By optimizing tundish flow, steel plants experience:

-

Fewer inclusions in slabs or billets

-

Improved surface quality

-

Higher casting speeds

-

More stable multi-strand operations

-

Reduced clogging at the nozzle

-

Longer tundish campaign life

It is a direct pathway to cleaner, more consistent steel — without major changes to upstream or downstream systems.