Crane tracks are subject to complex forces, including torsional stress, lateral loads, and dynamic weight shifts. Poor design can lead to uneven load distribution, track misalignment, and premature wear. This blog explores torsion effects, force distribution challenges, and best design practices to enhance stability and operational efficiency.

Crane tracks used in open yard environments face unique challenges, including weather exposure, temperature fluctuations, and increased lateral forces. Unlike indoor installations, these tracks must be engineered for durability, stability, and resistance to environmental conditions. This blog explores the key factors in designing crane rail systems for open yards and best practices for ensuring long-term performance.

Ensuring stability and fatigue resistance in crane tracks is essential for maintaining safety, longevity, and operational efficiency. Over time, repeated loading and environmental factors can cause material fatigue, misalignment, and structural degradation. This blog explores the critical factors affecting stability, common fatigue issues, and best practices for preventing premature failures.

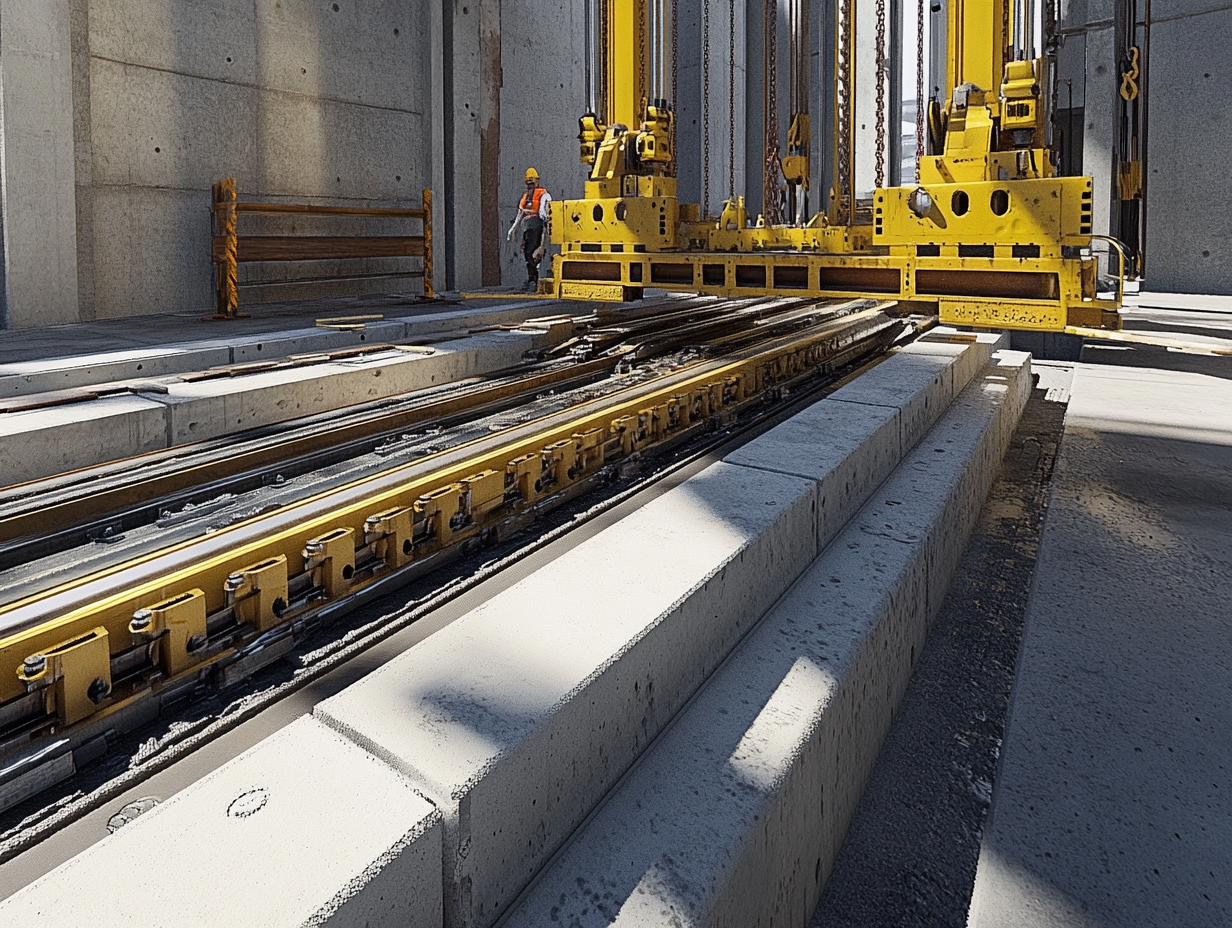

Proper crane rail installation and bedding systems are essential for ensuring stability, durability, and reduced maintenance costs. Incorrect installation or improper bedding can lead to wear, deformation, and misalignment. This blog explores crane rail installation techniques, bedding systems, and key considerations for optimal performance.

Crane tracks must handle not only vertical loads but also lateral forces and torsion (twisting effects). Insufficient torsional resistance or uncontrolled lateral forces can cause rail deformations, crane instability, and serious operational issues. This blog explores how torsion is managed in crane tracks and the methods used to control lateral forces for optimal stability.

Crane tracks are subjected to heavy loads daily, making stability and fatigue analysis essential. Poorly designed crane tracks can lead to deformation, system failures, and costly downtime. This blog explores best practices for ensuring track stability and fatigue resistance.

Crane tracks are critical for moving heavy loads in industrial facilities. Their design varies based on crane type and operational requirements. Generally, single-span and multi-span crane track systems are used. In this blog, we compare these two systems, exploring their advantages, disadvantages, and best-use cases.

For crane tracks to operate safely and efficiently, they must meet specific tolerance standards. Misaligned rails can cause excessive wear on crane wheels, rail bending, and system failures.

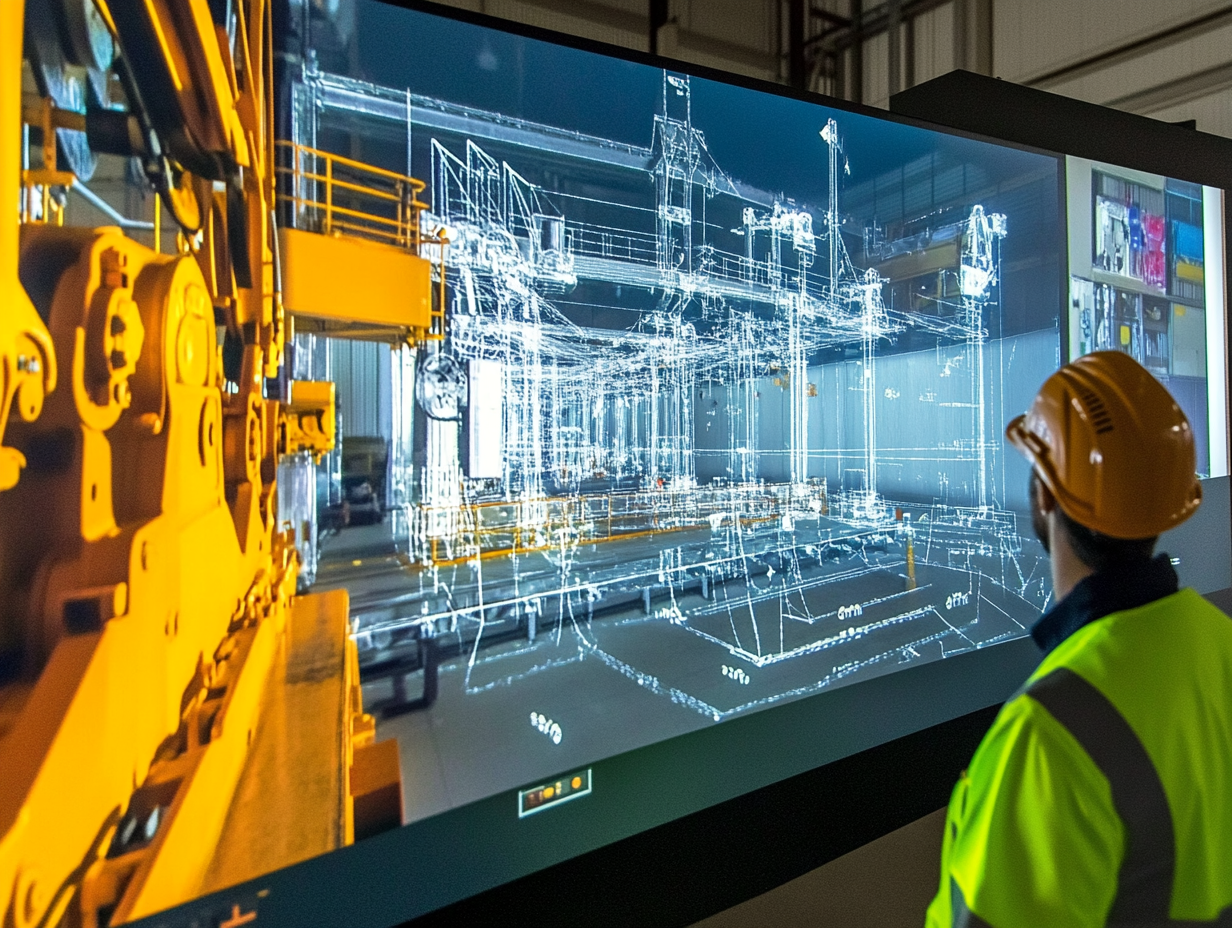

The safety and efficiency of crane tracks depend on the accuracy of the structural construction. The quality of steel structures, connection details, and design tolerances ensure long-lasting and trouble-free operation.

Crane tracks are engineering marvels designed to safely transport heavy loads. However, the reliability and durability of these systems depend heavily on the materials used and the design choices made.

Crane tracks are essential components of industrial systems, enabling the safe and efficient movement of heavy loads. The proper selection and standard-compliant design of crane rails are crucial for both performance and safety.