When it comes to precision, consistency, and trust in engineering, few names carry as much weight as DIN — Deutsches…

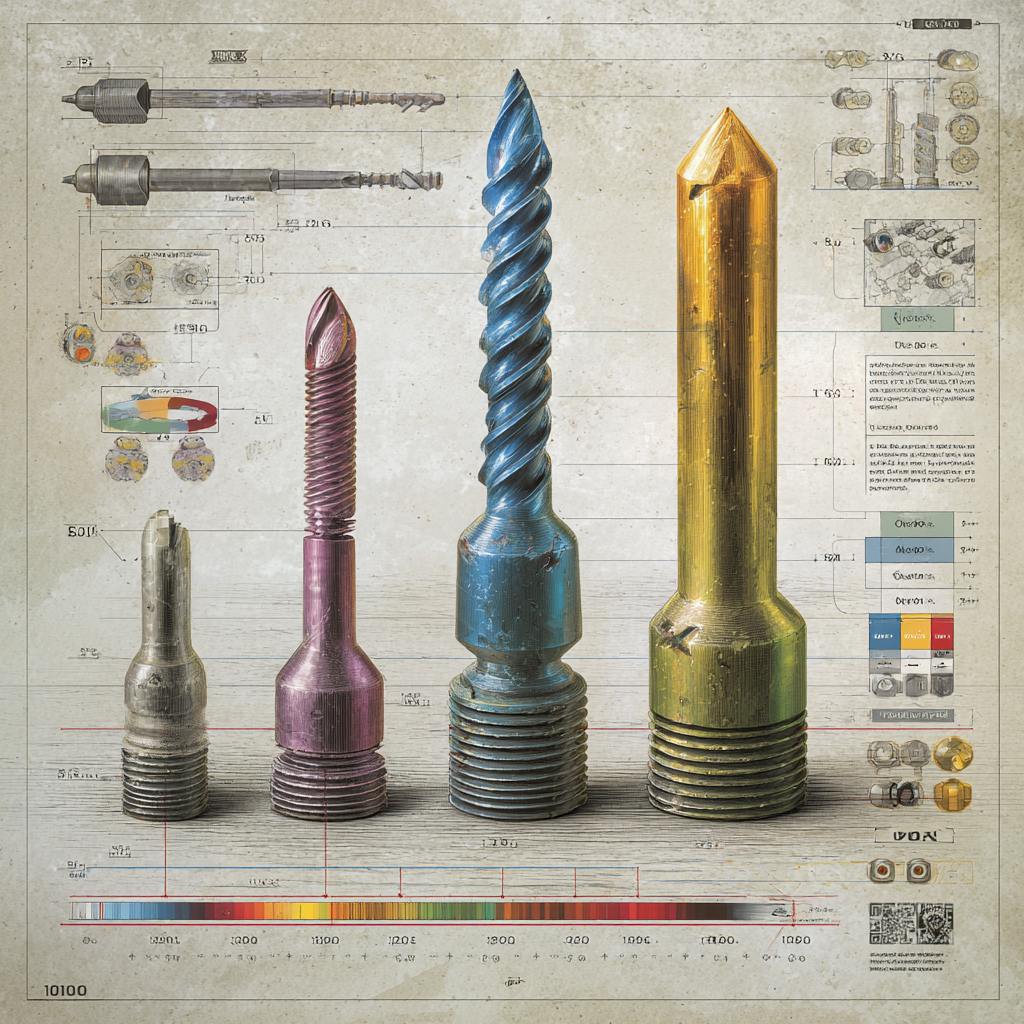

While standard drills and countersinks handle most machining tasks, specialized hole tools take precision and efficiency to the next level….

Taps and dies are the unsung heroes of engineering. They cut the precise threads that make bolts, screws, and nuts interchangeable worldwide — keeping mining machines, cars, and factories running smoothly.

Drills may create holes, but for true precision and durability, countersinks and center drills take the stage. These tools refine, guide, and prepare holes so that fasteners fit perfectly and machining remains accurate.

If dies create the external threads on bolts and rods, then taps are their natural counterpart cutting the internal threads…

Threads are everywhere from the screws in your phone to the massive bolts holding mining equipment together. But how are these precise spiral grooves created? The answer lies in taps and dies, guided by DIN standards.

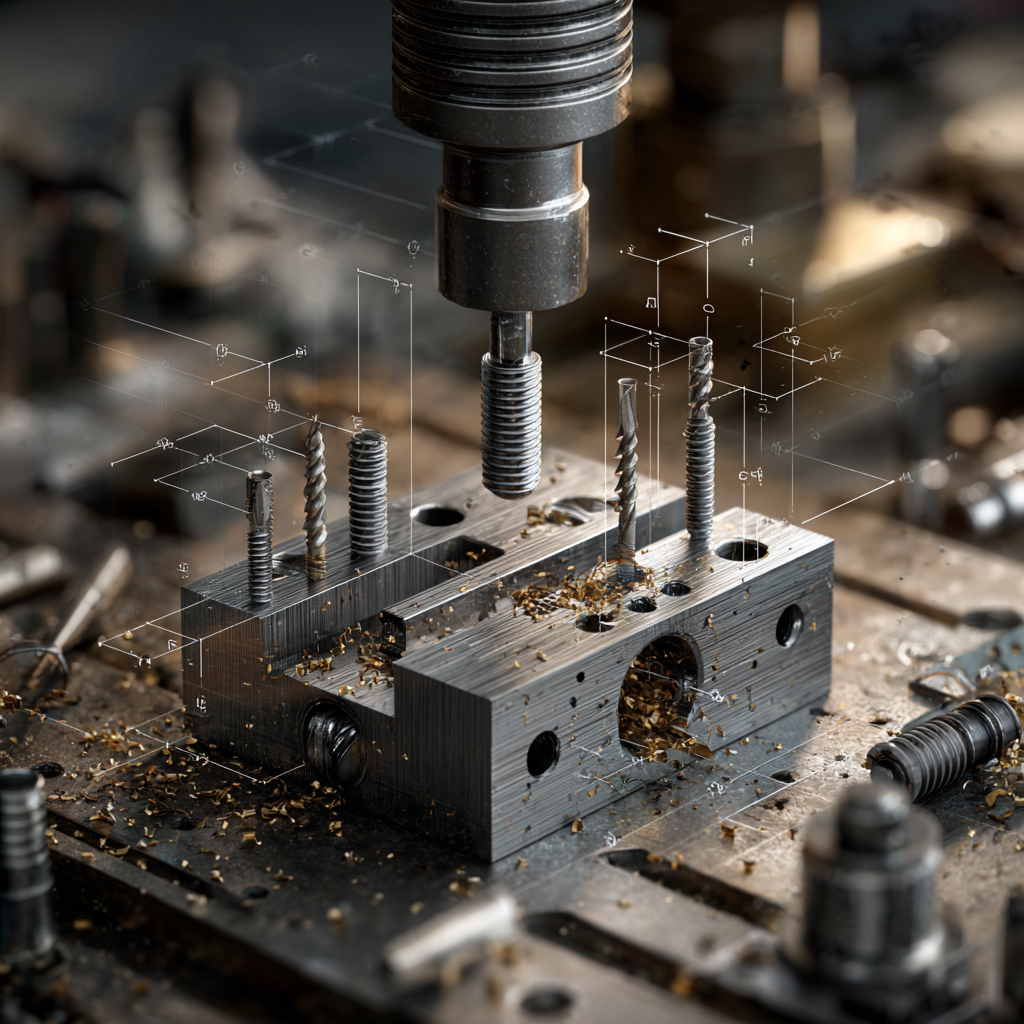

When it comes to machining steel, one of the most common tasks is creating precise holes. From simple fasteners to complex machine assemblies, holes must be accurate, smooth, and reliable. This is where drills and reamers — guided by DIN standards — play a central role.

In metal forming and sheet processing industries, the relationship between material thickness and bending radius is a cornerstone of production quality. Incorrectly calculated bending radii can lead to material cracking, deformation, or structural failure.