Steel construction plays a fundamental role in ensuring the structural integrity, operational efficiency, and safety of cranes used in various industries, from mining to logistics. As one of the most critical engineering aspects of lifting systems, a solid grasp of steel construction principles can significantly influence design decisions and long-term performance.

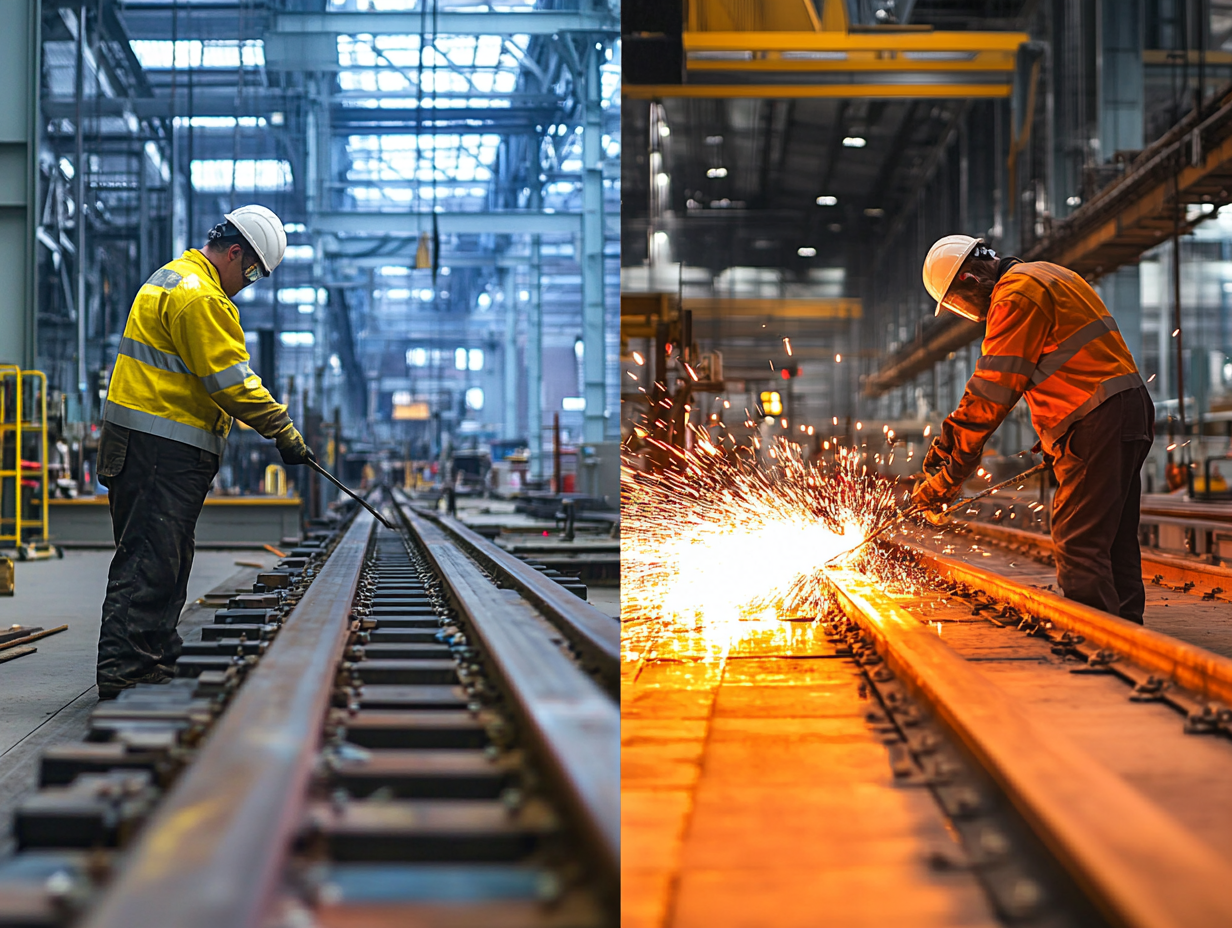

Crane rail maintenance is essential for ensuring safety, efficiency, and long-term durability. Companies often choose between preventive maintenance, which focuses on scheduled inspections and early issue detection, and reactive maintenance, which addresses failures as they occur. This blog explores the advantages and risks of both approaches, helping you implement an optimal rail maintenance strategy.

Crane rails are subjected to continuous mechanical stress, heavy loads, and environmental factors, which can cause wear and deformation over time. Without proper management, these issues can lead to misalignment, increased maintenance costs, and safety risks. This blog explores the causes of rail wear, strategies to minimize deformation, and best practices for extending rail lifespan.

Crane tracks must handle not only vertical loads but also lateral forces and torsion (twisting effects). Insufficient torsional resistance or uncontrolled lateral forces can cause rail deformations, crane instability, and serious operational issues. This blog explores how torsion is managed in crane tracks and the methods used to control lateral forces for optimal stability.

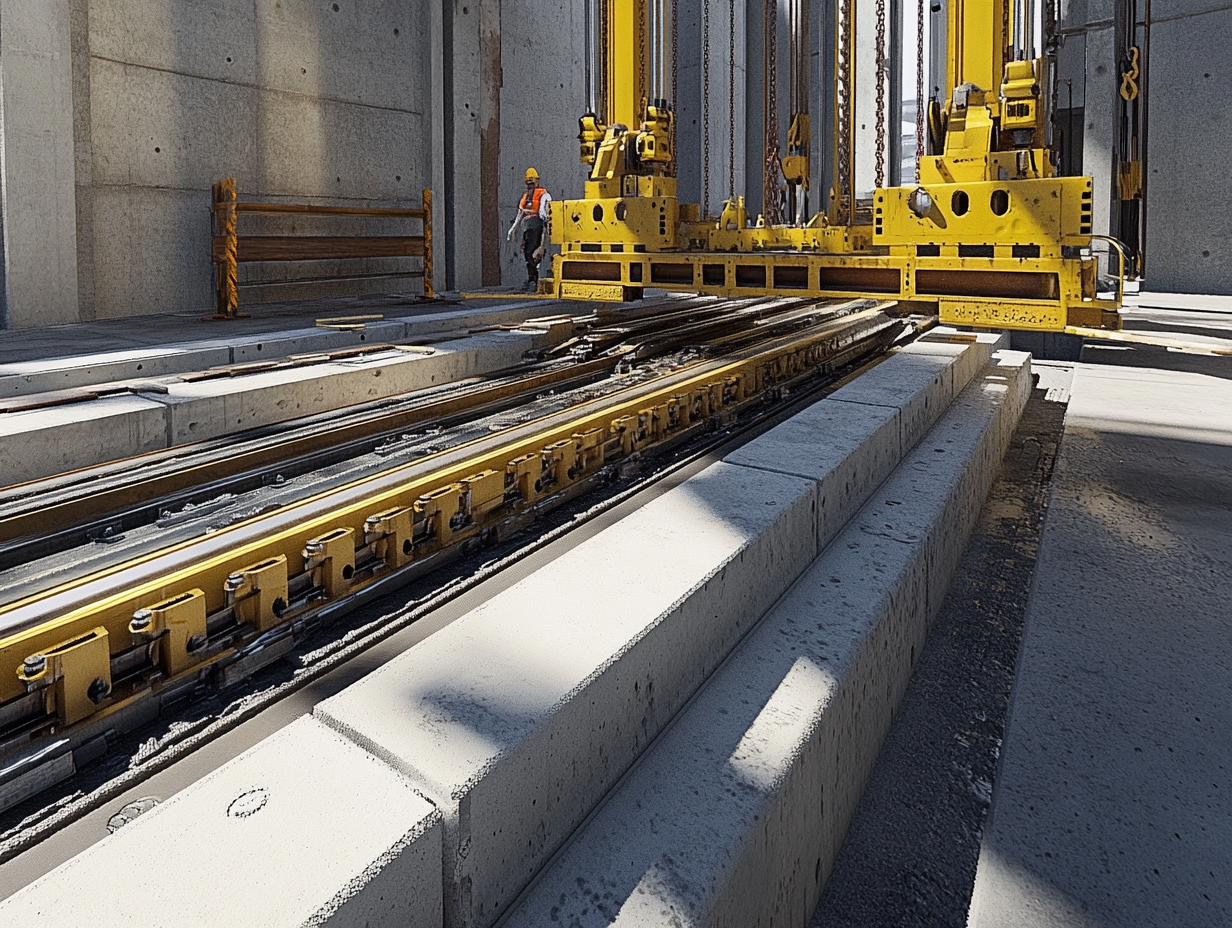

For crane tracks to operate safely and efficiently, they must meet specific tolerance standards. Misaligned rails can cause excessive wear on crane wheels, rail bending, and system failures.

Crane tracks are engineering marvels designed to safely transport heavy loads. However, the reliability and durability of these systems depend heavily on the materials used and the design choices made.

Crane tracks are essential components of industrial systems, enabling the safe and efficient movement of heavy loads. The proper selection and standard-compliant design of crane rails are crucial for both performance and safety.

In casting processes, material utilization is a critical factor that directly impacts product quality and cost efficiency. Optimizing material usage not only streamlines production but also minimizes waste, leading to significant cost savings. Additionally, identifying and addressing potential defects early in the process enhances the durability and functionality of the final product.

In industrial processes, the quality and durability of each component are crucial for production efficiency, safety, and longevity. Steltech spiral…

- Genel

-

CompressionSprings, CorrosionResistance, CorrosionResistantSprings, Customization, CustomSprings, DiscSpringApplications, EngineeringSolutions, ForceTestedSprings, HeatResistantSprings, HeavyDutySprings, HighDurability, HighLoadCapacity, HighTemperatureResistance, IndustrialApplications, IndustrialComponents, IndustrialSprings, PrecisionEngineering, ReliablePerformance, SpiralDiscSprings, SpringCustomization, Springs, SteelMaking, SteelProductionSprings, SteltechSprings, TemperatureResistantSprings