Cold bending is a critical process that allows for precise shaping of metals at room temperature. Accurate dimensional calculations ensure the integrity, durability, and functionality of the final product.

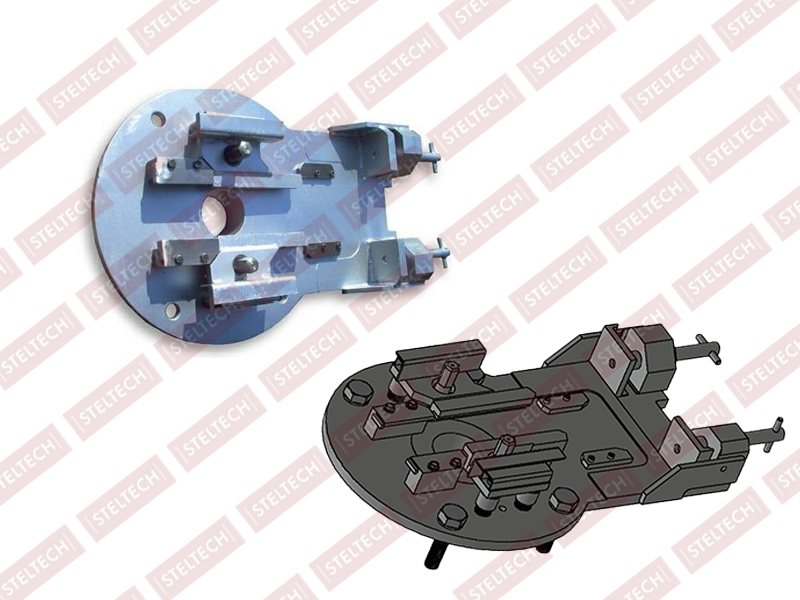

Tundish mechanisms are specialized equipment used in the metal casting industry to control and safely transfer molten metal into molds. These mechanisms ensure precision and reliability at every stage of the casting process, thereby enhancing the quality of the final product. Tundish mechanisms play a crucial role, especially in the casting of metals such as steel, aluminum, and copper.