Strength You Can Measure In steel manufacturing, quality isn’t assumed — it’s proven.Every beam, sheet, and rebar that leaves a…

Every great creation starts with a recipe and steel is no exception.From bridges and skyscrapers to cars and cargo ships,…

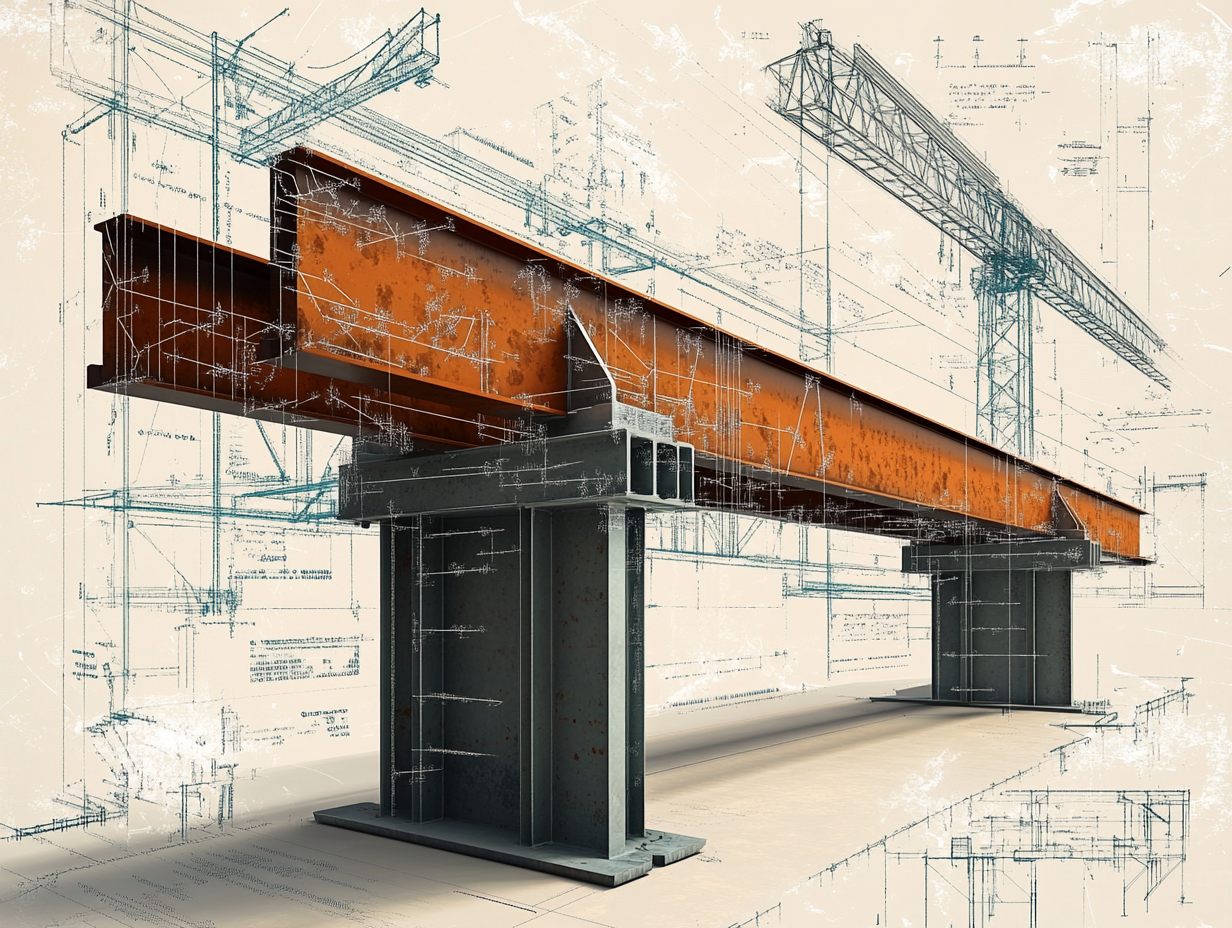

In mining infrastructure and heavy machinery, beams are everywhere from conveyor support frames to equipment platforms and structural walkways. One of the most common configurations is the simply supported beam, where the beam is supported at both ends but free to bend under load.

In the world of mining machinery and structural engineering, components rarely face a single type of stress. Instead, they often…

In mining and heavy industrial environments, components like beams, shafts, and structural arms often face intense loading that causes them…

Bolts are a critical component in steel construction, used for securing connections, distributing loads, and maintaining structural integrity. Choosing the right bolt type ensures safety, durability, and performance in bridges, buildings, industrial plants, and machinery. This blog explores the different types of bolts, their characteristics, and applications in steel structures.

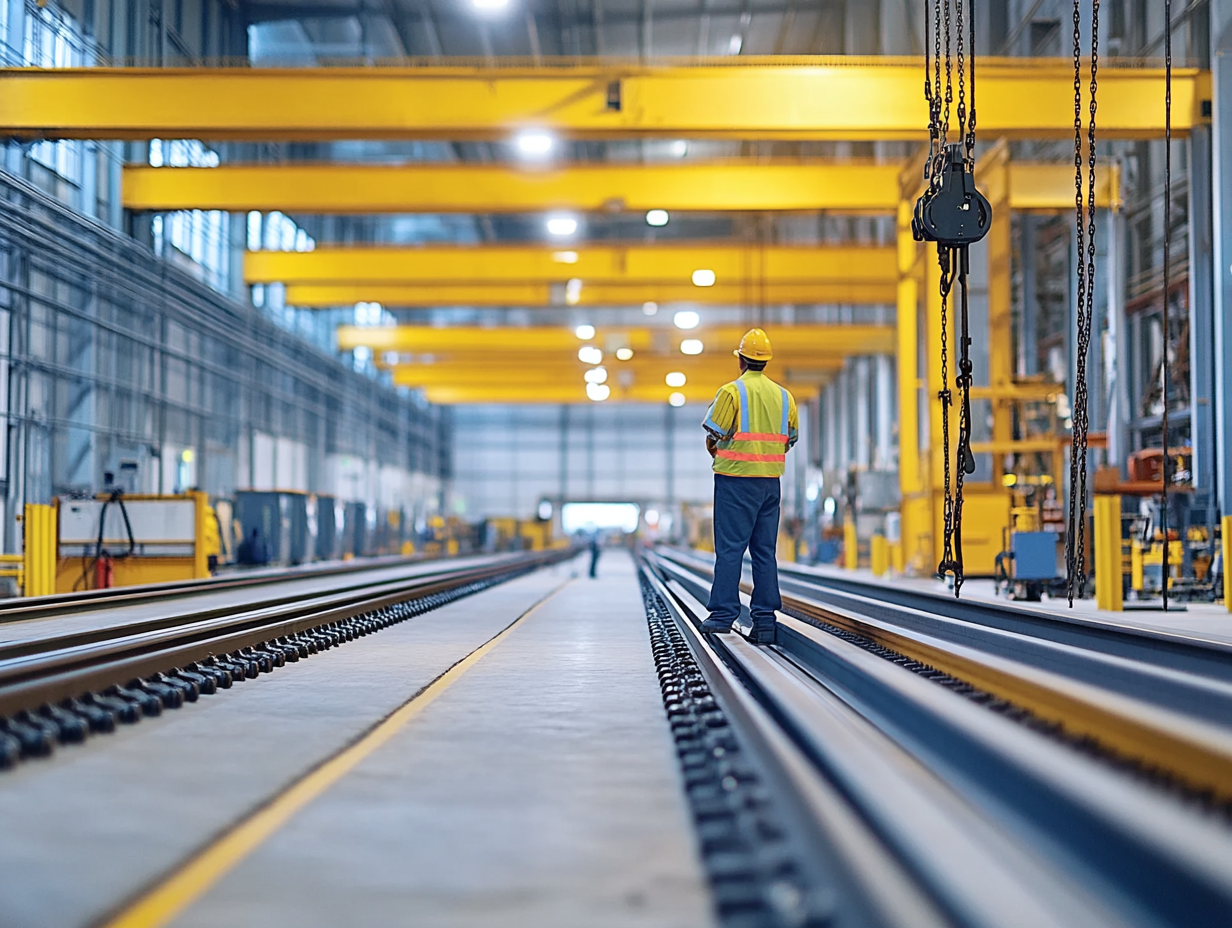

The choice of rail profile significantly affects crane movement, load distribution, and long-term operational efficiency. Selecting the wrong profile can result in excessive wear, misalignment, and high maintenance costs. This blog explores how different rail profiles influence crane performance and what factors to consider for optimal selection.

Crane tracks are subject to complex forces, including torsional stress, lateral loads, and dynamic weight shifts. Poor design can lead to uneven load distribution, track misalignment, and premature wear. This blog explores torsion effects, force distribution challenges, and best design practices to enhance stability and operational efficiency.

Proper installation of crane track rails is essential for ensuring alignment, structural integrity, and long-term durability. Poorly installed rails can lead to misalignment, excessive wear, and increased maintenance costs. This blog explores the best installation techniques, welding methods, and industry standards to follow for optimal crane track performance.

Selecting the right crane rail profile is essential for ensuring stability, load-bearing capacity, and durability in industrial operations. While DIN 536 A, DIN 536 F, and standard railway rails are commonly used, each has distinct design characteristics and applications. This blog explores their differences, advantages, and ideal use cases.

Flat bar crane rails, also known as laminated rails, are a widely used alternative to traditional crane rail profiles. These rails are particularly favored in light to medium-duty applications, offering flexibility and cost-effectiveness. However, they also come with specific limitations that must be considered when designing crane track systems. This blog explores the pros and cons of flat bar crane rails and their ideal applications.

Crane rail selection is a critical decision that directly impacts safety, efficiency, and long-term durability in industrial operations. Choosing the wrong rail can lead to premature wear, misalignment, and costly maintenance. This blog explores the essential factors to consider when selecting the right crane rail for your system.

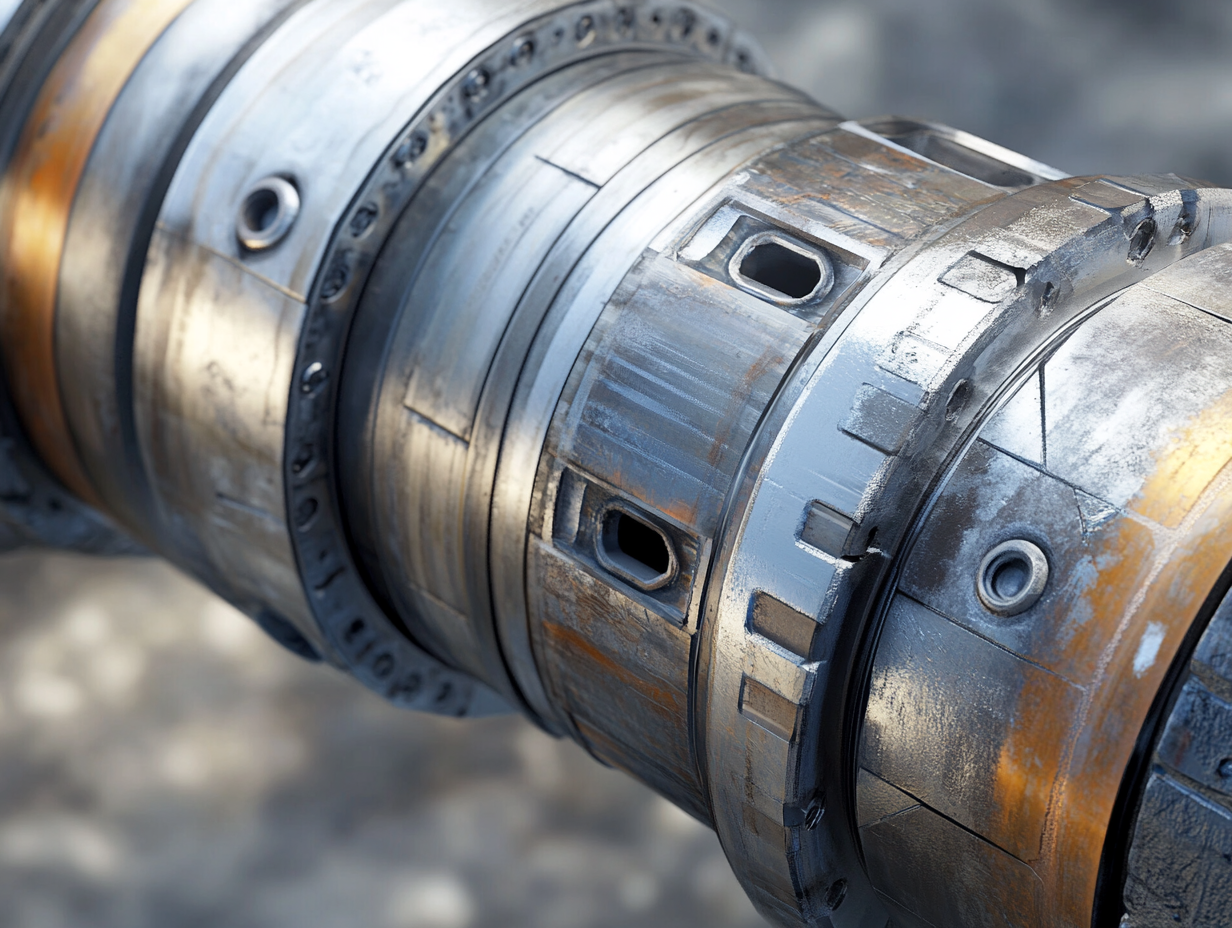

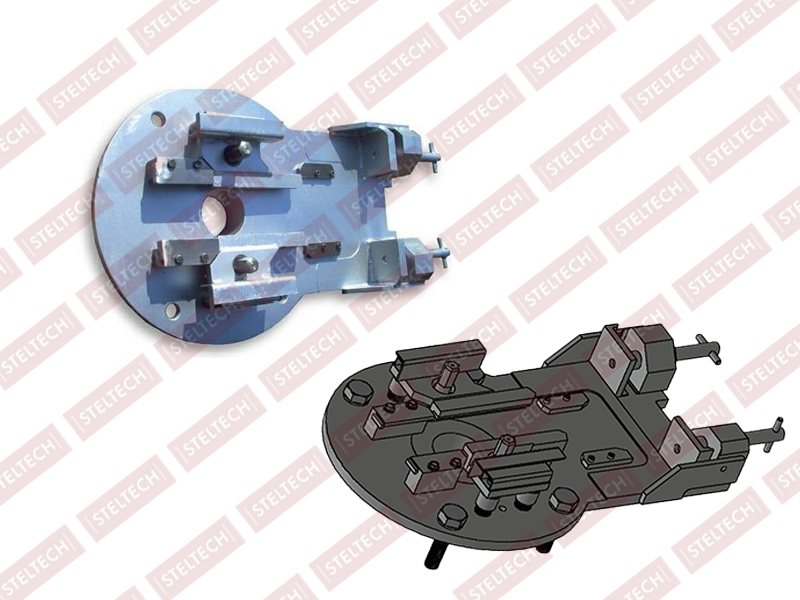

Tundish mechanisms are specialized equipment used in the metal casting industry to control and safely transfer molten metal into molds. These mechanisms ensure precision and reliability at every stage of the casting process, thereby enhancing the quality of the final product. Tundish mechanisms play a crucial role, especially in the casting of metals such as steel, aluminum, and copper.

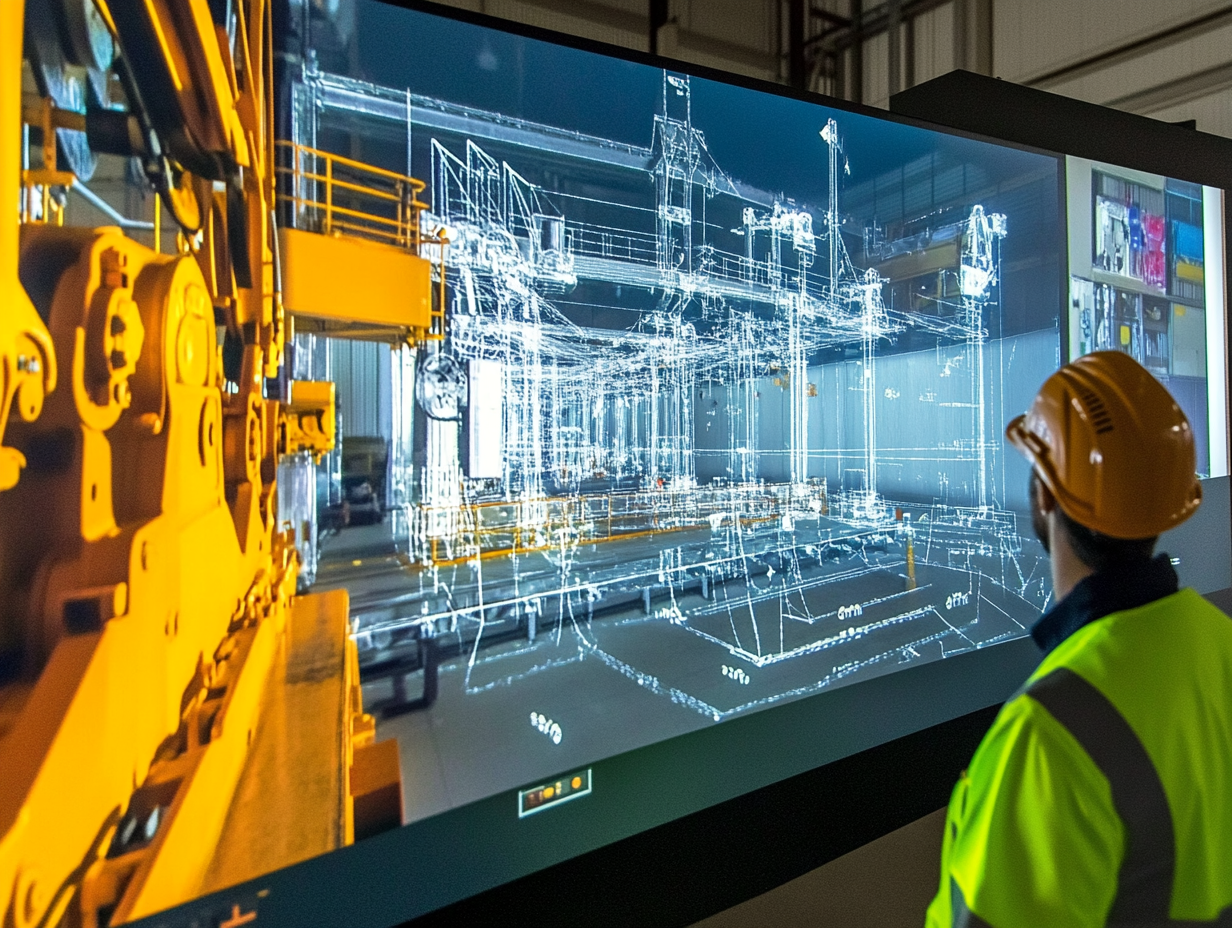

At Steltech, our commitment to quality and safety is unparalleled. In the world of engineering and construction, ensuring that materials are robust and fit for purpose is paramount. One of the key methods to assure material quality and structural integrity is through Nondestructive Testing (NDT). Today, we’re delving deep into one of the most fundamental NDT methods: Visual Inspection.

Stacker reclaimer is one of the heavy machines used in the bulk material handling industry, especially in ports, terminals, steel plants, and mines, providing a functional solution for both material stacking and reclaiming processes.

Tundish mechanisms are an essential part of the steelmaking process. They help regulate the flow of molten steel from the ladle to the mold or another vessel. There are different types of tundish mechanisms, such as the plunger mechanism, level controller mechanism, flow control valves, and launder system.

- Blog, Machinery

-

EfficiencyImprovement, EngineeringMaintenance, FlowControl, HighQualitySteel, IndustrialEngineering, MoltenSteel, ReducingDefects, RegularMaintenance, SkilledTechnicians, steelindustry, SteelMakingProcess, SteelManufacturing, SteelOutput, SteelProduction, SteelProductQuality, SteelValue, SurfaceDefectsPrevention, TundishInspection, TundishMechanisms