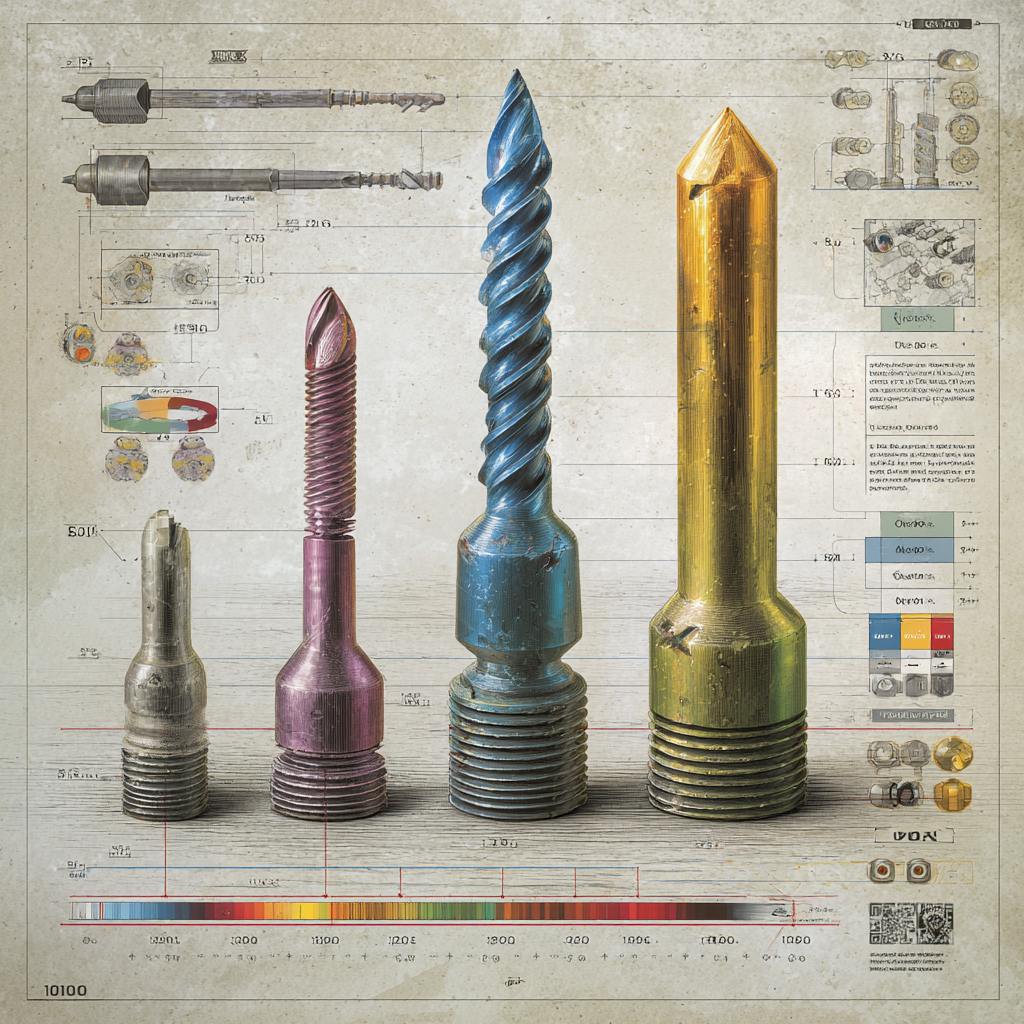

Drills may create holes, but for true precision and durability, countersinks and center drills take the stage. These tools refine, guide, and prepare holes so that fasteners fit perfectly and machining remains accurate.

Threads are everywhere from the screws in your phone to the massive bolts holding mining equipment together. But how are these precise spiral grooves created? The answer lies in taps and dies, guided by DIN standards.

When it comes to machining steel, one of the most common tasks is creating precise holes. From simple fasteners to complex machine assemblies, holes must be accurate, smooth, and reliable. This is where drills and reamers — guided by DIN standards — play a central role.