While standard drills and countersinks handle most machining tasks, specialized hole tools take precision and efficiency to the next level….

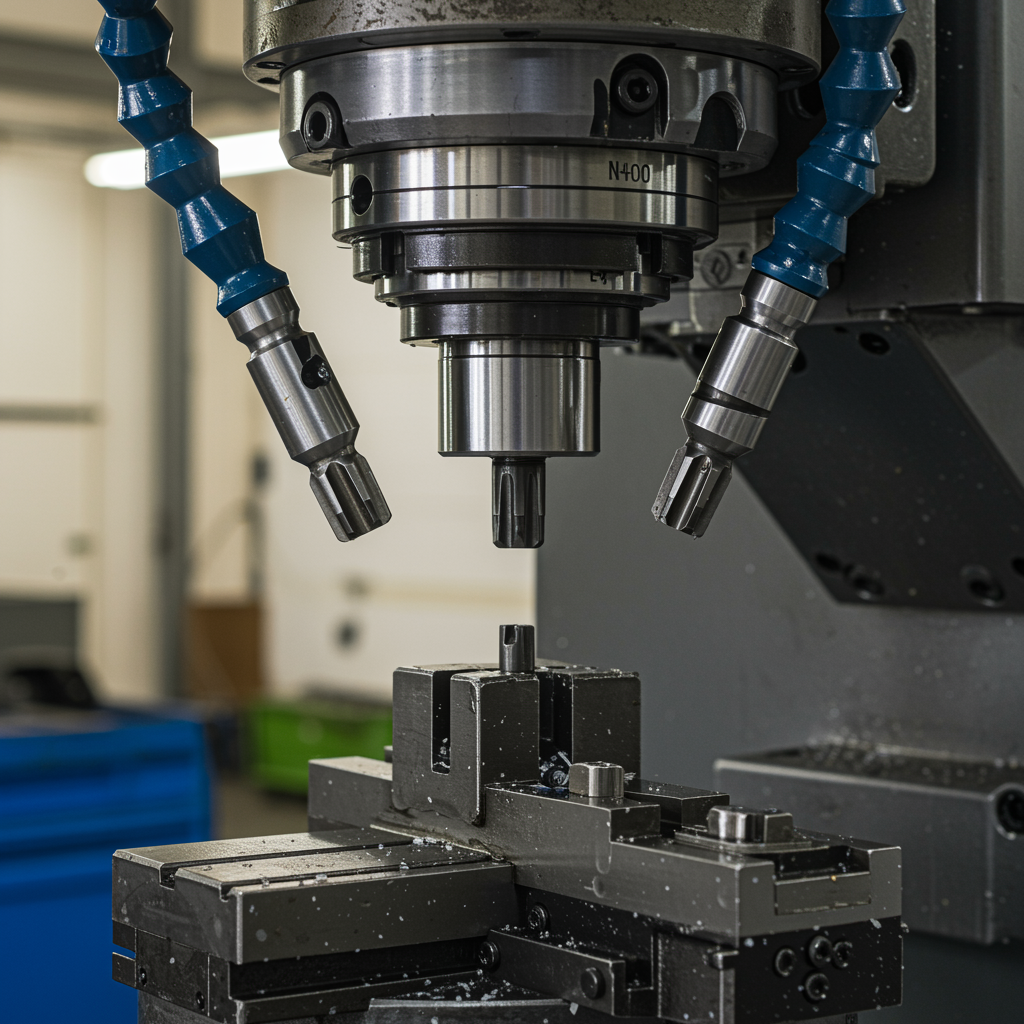

Behind every powerful machine tool lies a simple question: how does the tool connect securely to the machine? This is where standards like DIN 10 and DIN 138 come in. They define the dimensions of shanks and sockets the “handshake” between tools and machines.

When it comes to shaping and machining steel, precision is everything. A drill bit labeled “5mm” must always measure 5mm, no matter who manufactured it. This is where DIN standards (Deutsches Institut für Normung) come into play. Established in Germany, DIN ensures that tools and components are consistent, reliable, and interchangeable.