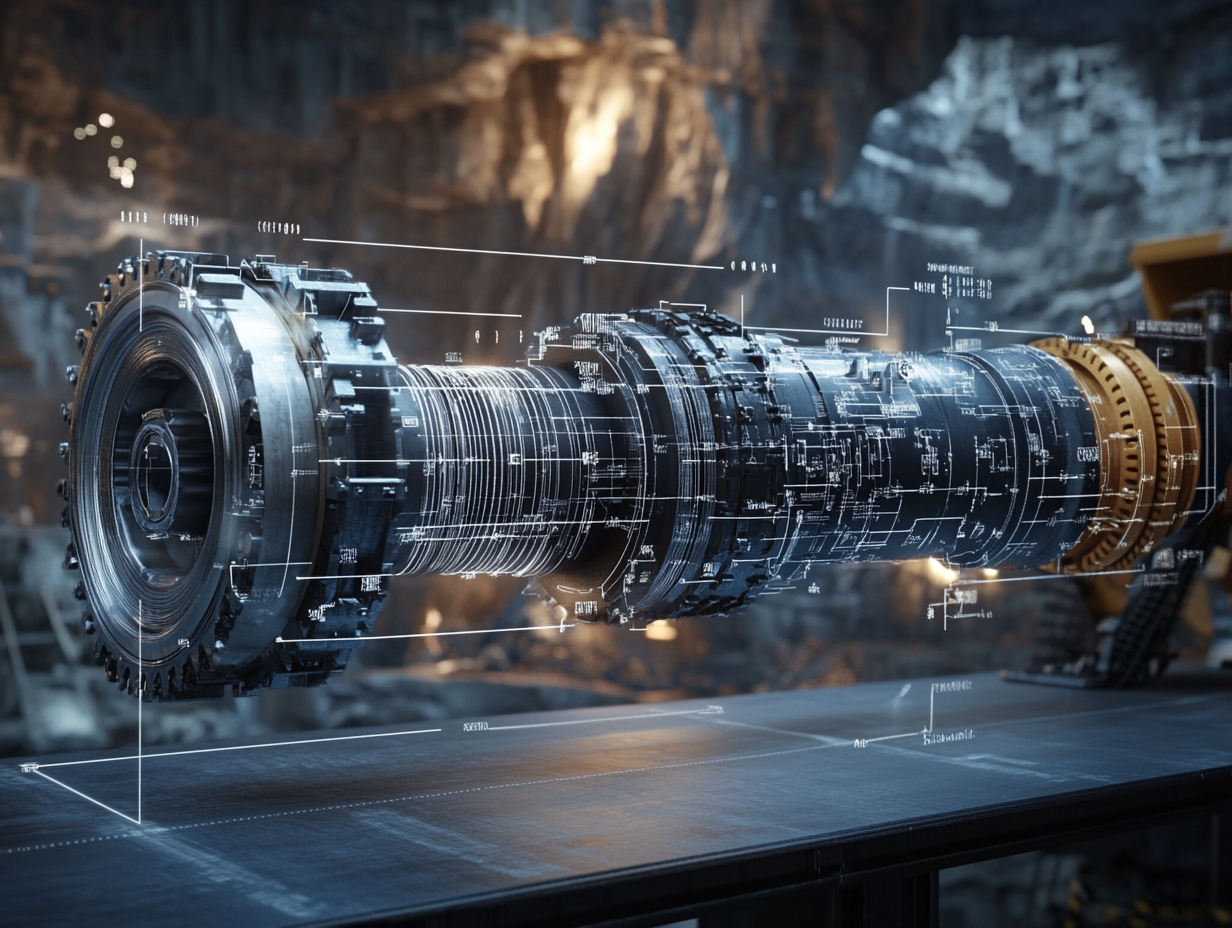

In the design of shafts, rods, and cylindrical components — especially in mining and heavy industrial machinery — rotational symmetry…

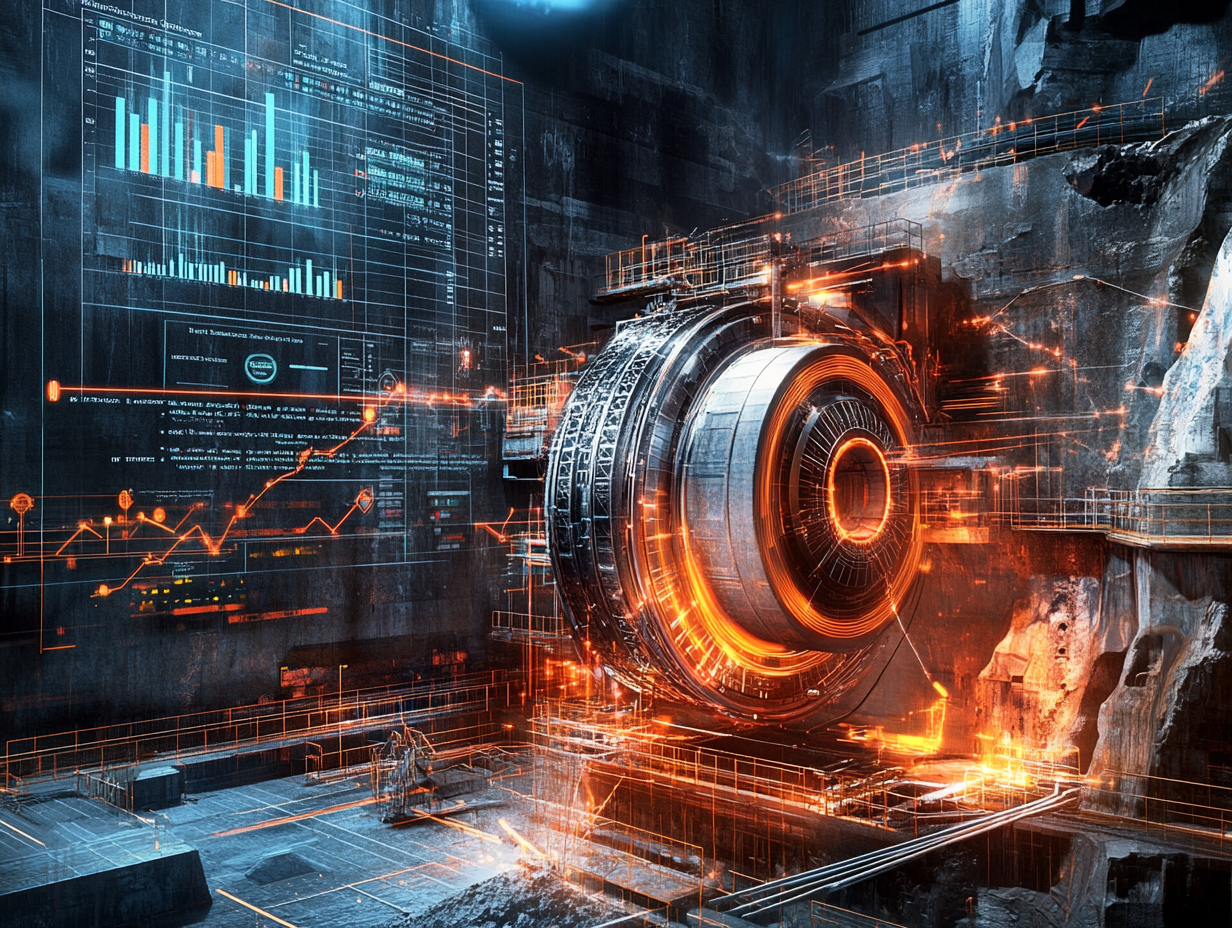

In mining and heavy industrial machinery, shafts are rarely subjected to just one type of load. Instead, they typically experience…

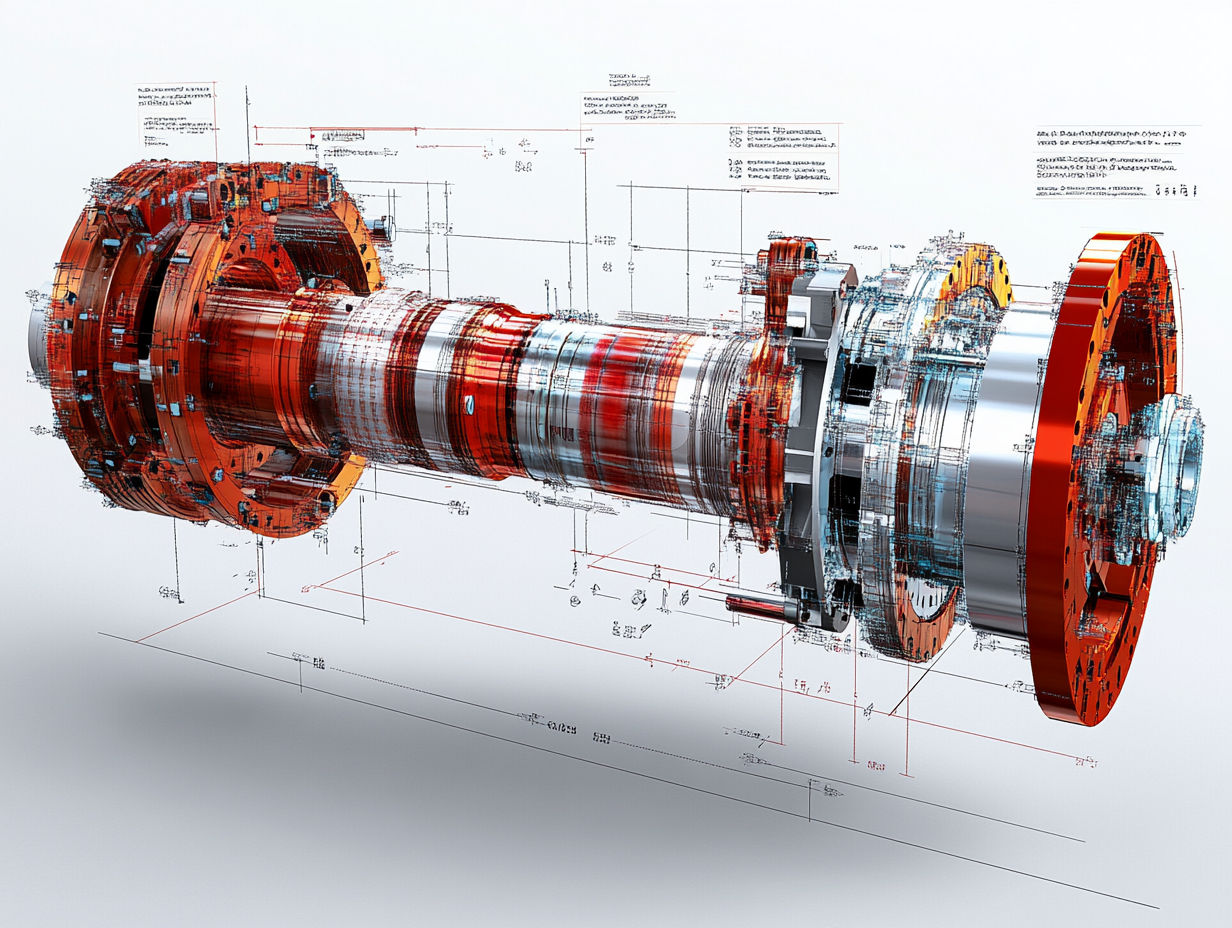

No matter how precise your calculations are, real-world uncertainties always exist in mechanical design. Material imperfections, dynamic loads, wear, and…

In the real world, components rarely experience a single, clean load. Instead, they’re often subjected to multiple forces acting in different directions. When it comes to shafts, axles, beams, and structural frames in mining and heavy industry, this results in combined bending moments, which must be carefully calculated for safe and efficient design.

Every mechanical structure must be able to resist two fundamental types of forces: tension (pulling) and compression (pushing). These are…

In mechanical and structural design especially for shafts, axles, and beams in mining machinery two critical stress types must be carefully evaluated: bending stress and shear stress.

In real-world engineering, components are rarely perfect cylinders or uniform beams. They include keyways, shoulders, holes, notches, and grooves — all of which introduce local stress intensification. This phenomenon is measured using the Stress Concentration Factor (SCF), known in engineering as Kt.

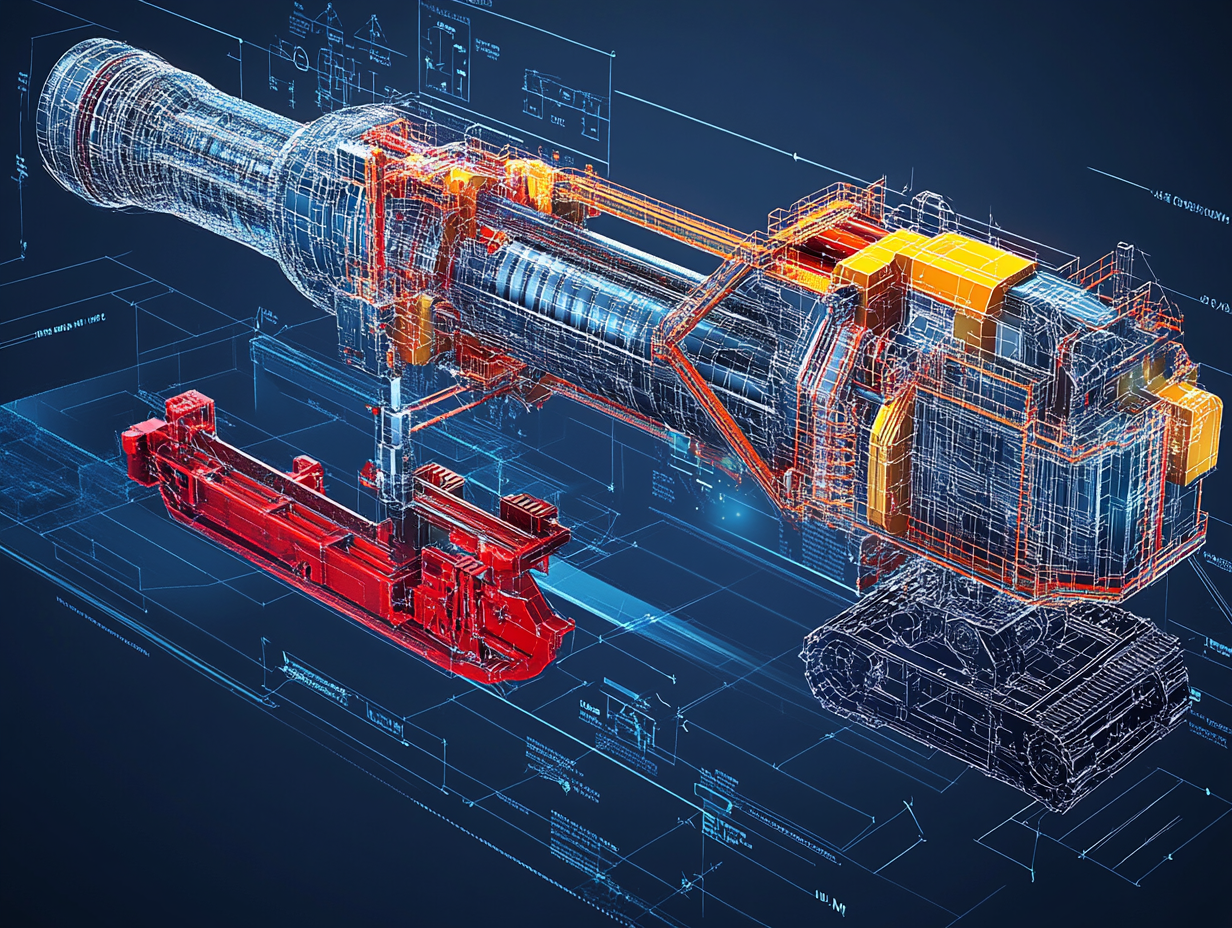

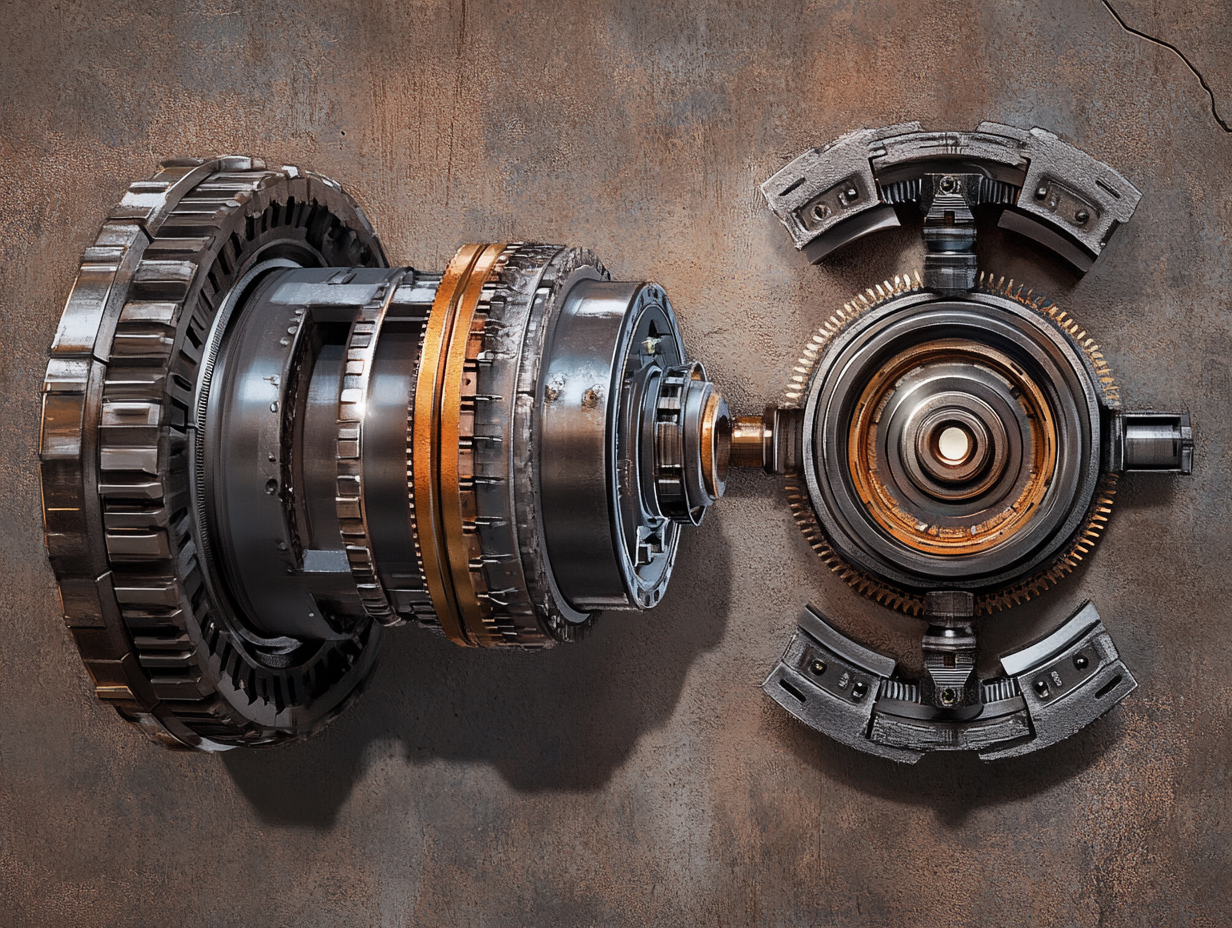

Accurate sizing of axles and shafts is crucial in the design of mechanical systems across mining, manufacturing, and heavy equipment sectors. Whether supporting load or transmitting torque, these components must be dimensioned to handle real-world conditions without failure, deflection, or premature fatigue.

Axles play a vital role in mechanical systems — especially in mining, transportation, and heavy lifting machinery. Whether they’re supporting wheel hubs, guiding rollers, or acting as pivot points for rotating components, axles are constantly exposed to complex stress conditions, including bending, shear, and torsion.

Choosing the right material for axles and shafts is one of the most critical steps in mechanical system design. These…

In the field of mechanical design and industrial engineering particularly within the mining, heavy machinery, and transportation sectors terms like axle, shaft, and journal are often used interchangeably. However, each component serves a distinct purpose in a mechanical system. Misunderstanding their roles can lead to design flaws, inefficiencies, or even system failure.

Selecting the right crane type is one of the most critical decisions in engineering operations, especially in sectors like mining, metallurgy, and manufacturing. Each crane design offers distinct advantages depending on operational demands, space constraints, and lifting capacities.

In this post, we’ll compare the three most common crane systems used in industrial and mining facilities: monorail cranes, double-girder overhead cranes, and gantry (portal) cranes.