Every mechanical structure must be able to resist two fundamental types of forces: tension (pulling) and compression (pushing). These are…

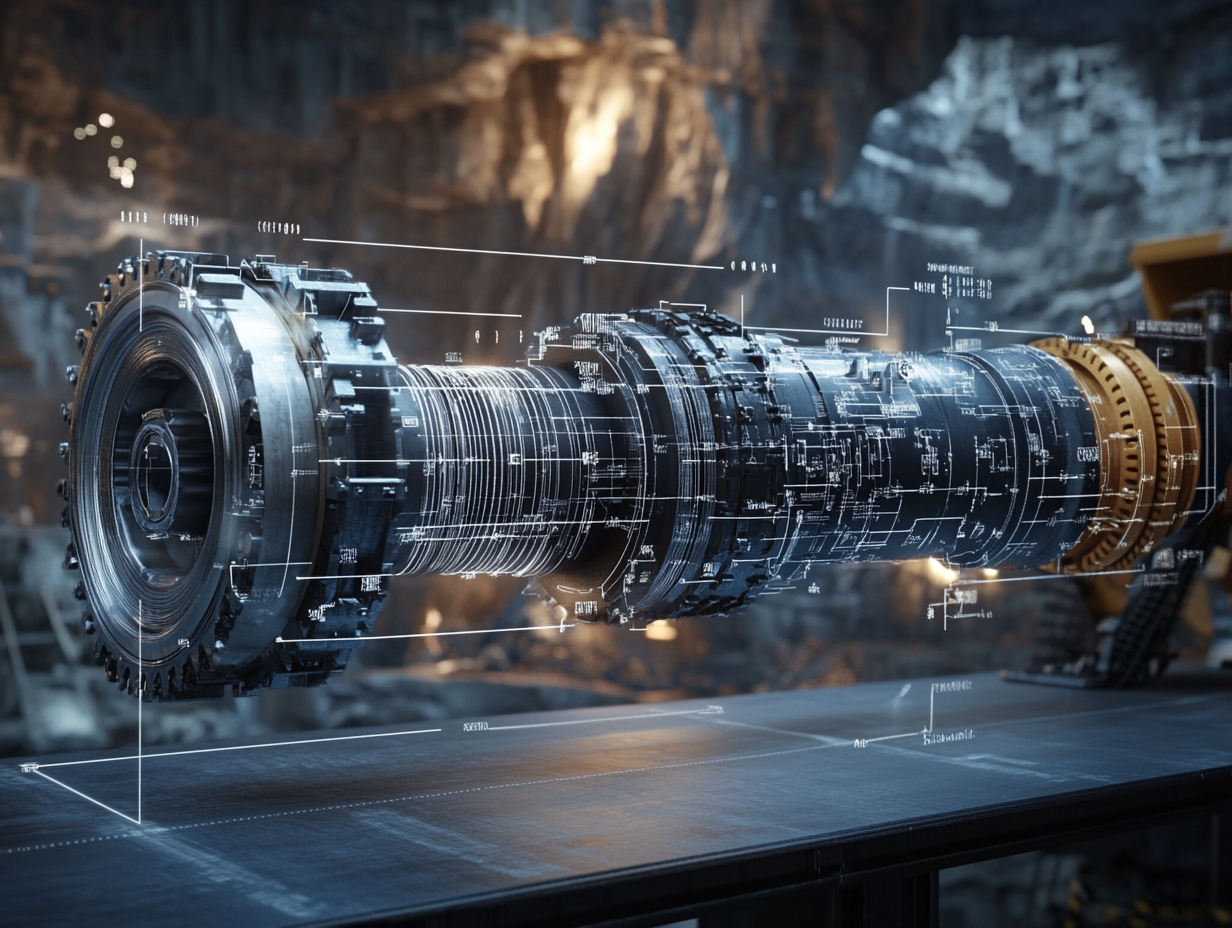

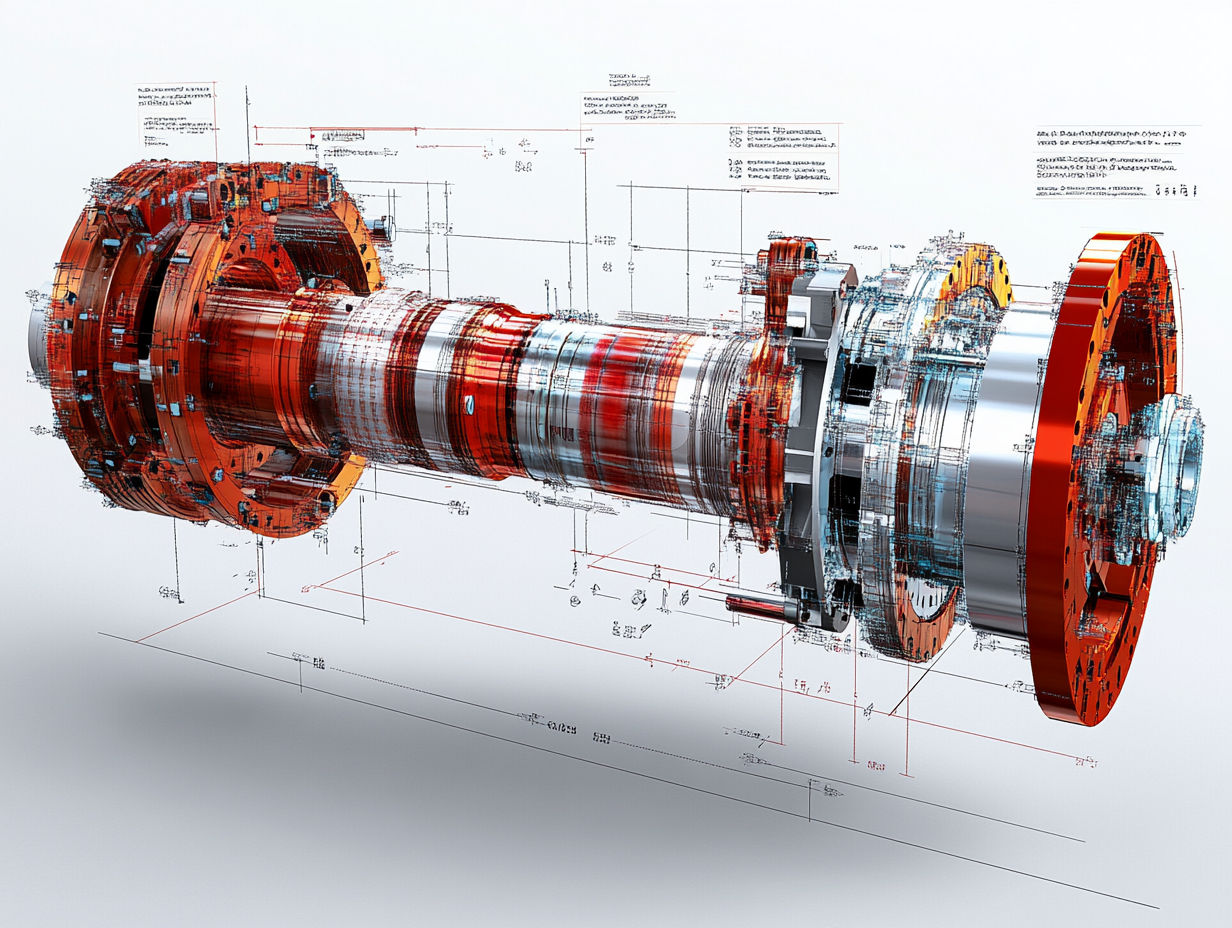

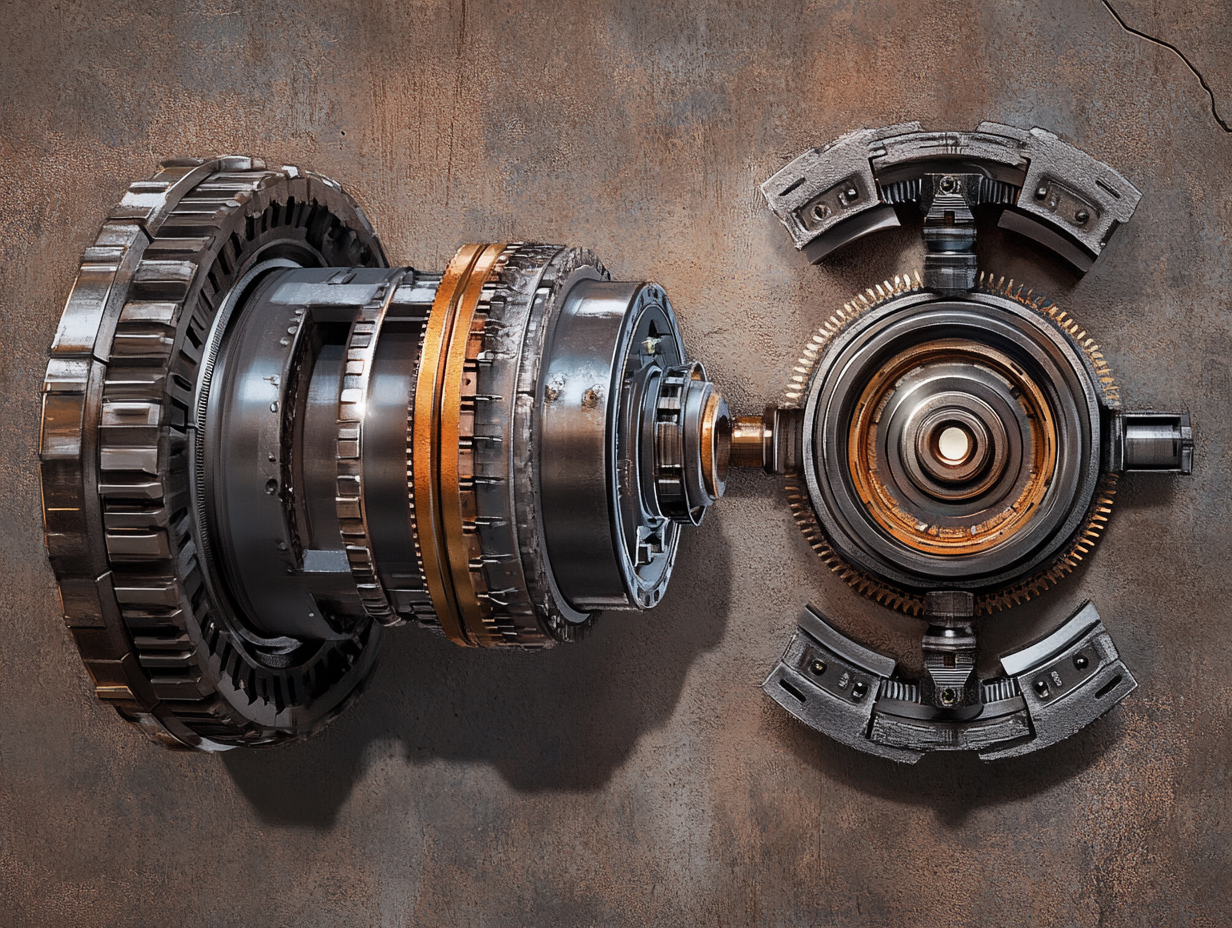

In mechanical and structural design especially for shafts, axles, and beams in mining machinery two critical stress types must be carefully evaluated: bending stress and shear stress.

In real-world engineering, components are rarely perfect cylinders or uniform beams. They include keyways, shoulders, holes, notches, and grooves — all of which introduce local stress intensification. This phenomenon is measured using the Stress Concentration Factor (SCF), known in engineering as Kt.

Accurate sizing of axles and shafts is crucial in the design of mechanical systems across mining, manufacturing, and heavy equipment sectors. Whether supporting load or transmitting torque, these components must be dimensioned to handle real-world conditions without failure, deflection, or premature fatigue.

Axles play a vital role in mechanical systems — especially in mining, transportation, and heavy lifting machinery. Whether they’re supporting wheel hubs, guiding rollers, or acting as pivot points for rotating components, axles are constantly exposed to complex stress conditions, including bending, shear, and torsion.

Choosing the right material for axles and shafts is one of the most critical steps in mechanical system design. These…

In the field of mechanical design and industrial engineering particularly within the mining, heavy machinery, and transportation sectors terms like axle, shaft, and journal are often used interchangeably. However, each component serves a distinct purpose in a mechanical system. Misunderstanding their roles can lead to design flaws, inefficiencies, or even system failure.

When designing steel crane structures especially those operating outdoors in mining, ports, and construction sites wind stability is a critical engineering concern. Even structures that are strong under static loads can fail due to lateral instability when subjected to wind, gusts, or pressure surges.

Behind every safe and reliable crane structure lies a deep layer of engineering logic — and at the heart of this logic are load group coefficients and hoisting load coefficients. These factors help engineers account for real-world operational conditions when calculating stresses, material fatigue, and safety margins.

When it comes to lifting heavy loads in mining, manufacturing, and port operations, equipment failure is not an option. That’s why industry professionals rely on rigorous standards like FEM (Fédération Européenne de la Manutention) to guide the design, classification, and load analysis of cranes.

In structural engineering, especially for cranes used in mining, knowing how a structure reacts to forces is the foundation of safe and efficient design. Two primary forms of load analysis are static and dynamic strength calculations — and they differ not just in theory, but in real-world performance, safety margins, and material behavior.

Understanding this distinction is critical when designing cranes, hoists, and material handling systems that operate in environments like open-pit mines, quarries, and coke plants, where loads vary constantly.

Selecting the right crane type is one of the most critical decisions in engineering operations, especially in sectors like mining, metallurgy, and manufacturing. Each crane design offers distinct advantages depending on operational demands, space constraints, and lifting capacities.

In this post, we’ll compare the three most common crane systems used in industrial and mining facilities: monorail cranes, double-girder overhead cranes, and gantry (portal) cranes.

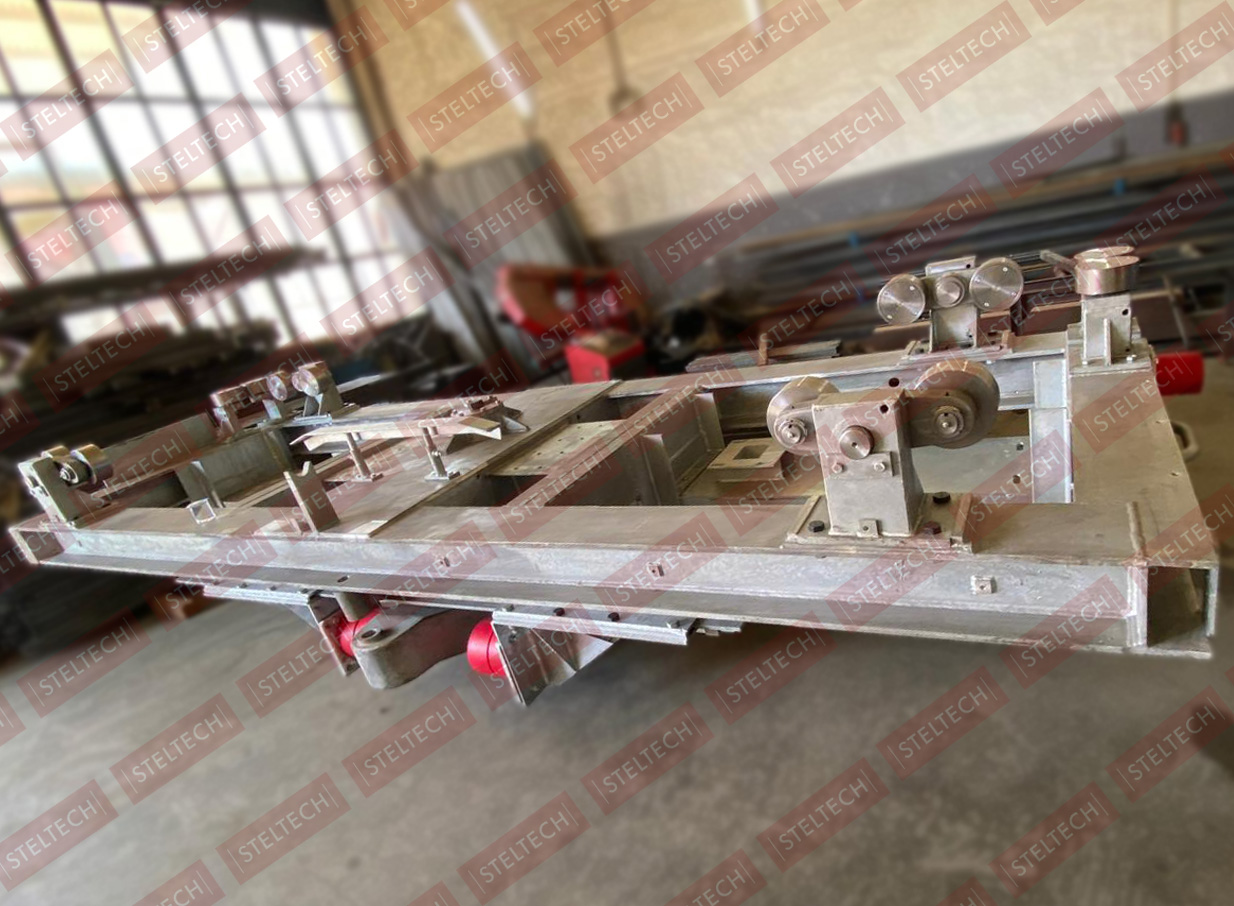

In the heart of every coke production facility lies a series of mechanical systems that ensure efficiency, safety, and continuity. One such critical component is the coal discharge plough, responsible for diverting, guiding, and discharging coal from conveyor systems during the coking process. This specialized equipment, manufactured with high precision by Steltech, plays a vital role in keeping coke plant operations smooth and uninterrupted.

In the world of crane construction, especially in mining and heavy industry, welded joints are some of the most critical stress points. These joints often endure repetitive dynamic loads, vibration, and environmental fatigue.

When designing crane structures — especially in mining, excavation, or industrial settings — it’s not enough to ensure the beam won’t break. You also need to ensure it won’t bend too much. That’s where deflection (sehim) comes into play. Controlled deflection is critical for precision, safety, and structural integrity during lifting operations.

Selecting the correct crane for a mining or industrial project isn’t just about lifting capacity — it’s about matching the machine to the expected usage intensity. This is where the concepts of load groups (B classes) and duty classes (H classes) come into play. These classifications help engineers and decision-makers choose cranes that won’t just work — they’ll last.

In the mining and heavy machinery industries, safety isn’t optional — it’s engineered into every bolt, beam, and weld. One of the most critical concepts in structural crane design is the use of safety factors. These mathematical buffers ensure that structures withstand not only known loads but also unexpected forces, imperfections, and usage variations. In essence, safety factors protect lives and investments.

In crane design — especially in heavy industries like mining and infrastructure — selecting the right steel is crucial. Two of the most commonly used structural steels are St37-2 and St52-3. Each has unique mechanical properties that make it suitable for different applications, environments, and load conditions. Understanding their differences is essential for engineers, designers, and project managers aiming to build safe, durable, and cost-effective cranes.

Understanding crane load conditions is essential in designing safe and reliable lifting systems — especially in demanding fields like mining, construction, and logistics. These classifications (H, HZ, and HS) define the environmental and operational stresses a crane is expected to handle. Selecting the correct condition is key to ensuring structural integrity and operational longevity.

Steel construction plays a fundamental role in ensuring the structural integrity, operational efficiency, and safety of cranes used in various industries, from mining to logistics. As one of the most critical engineering aspects of lifting systems, a solid grasp of steel construction principles can significantly influence design decisions and long-term performance.