Bringing a steel furnace to life is as fascinating as it is demanding. Unlike flipping a switch, reaching full production…

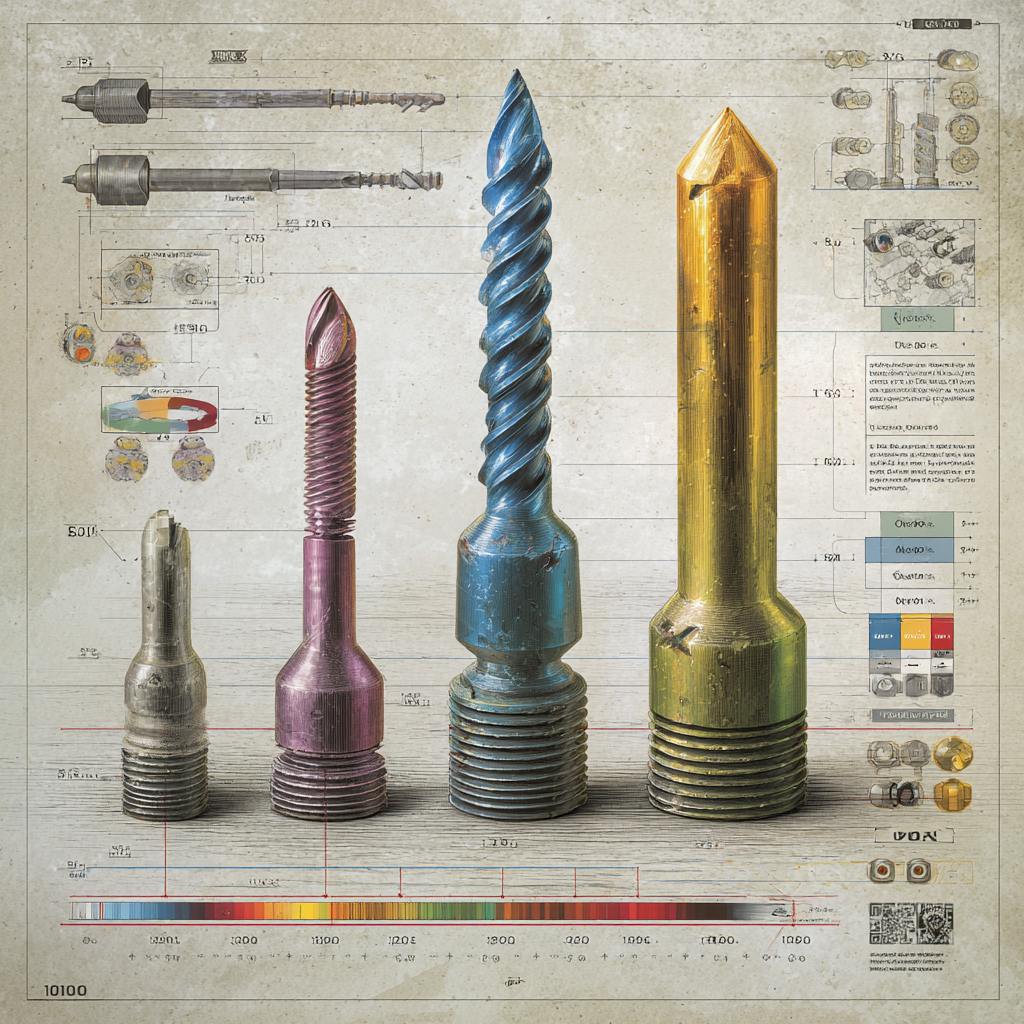

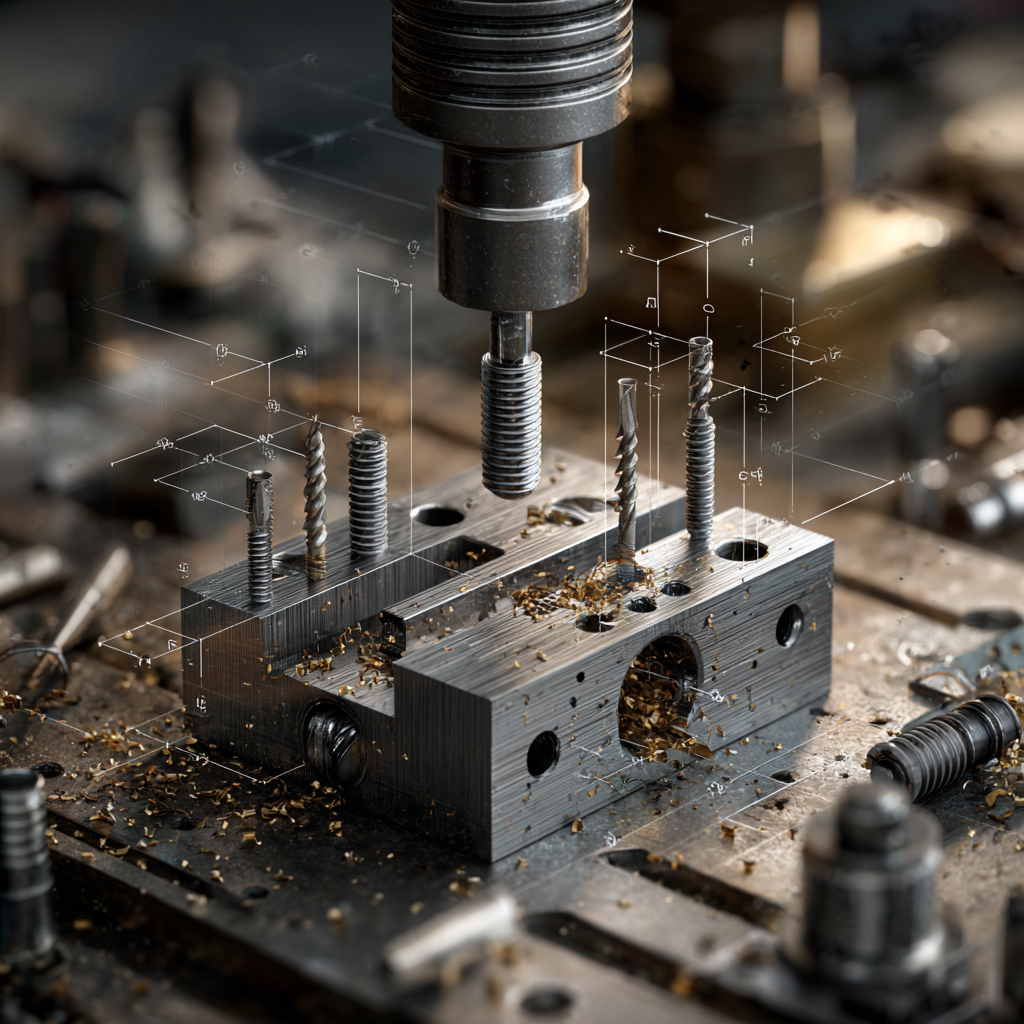

While standard drills and countersinks handle most machining tasks, specialized hole tools take precision and efficiency to the next level….

Taps and dies are the unsung heroes of engineering. They cut the precise threads that make bolts, screws, and nuts interchangeable worldwide — keeping mining machines, cars, and factories running smoothly.

Drills may create holes, but for true precision and durability, countersinks and center drills take the stage. These tools refine, guide, and prepare holes so that fasteners fit perfectly and machining remains accurate.

If dies create the external threads on bolts and rods, then taps are their natural counterpart cutting the internal threads…

When it comes to shaping and machining steel, precision is everything. A drill bit labeled “5mm” must always measure 5mm, no matter who manufactured it. This is where DIN standards (Deutsches Institut für Normung) come into play. Established in Germany, DIN ensures that tools and components are consistent, reliable, and interchangeable.

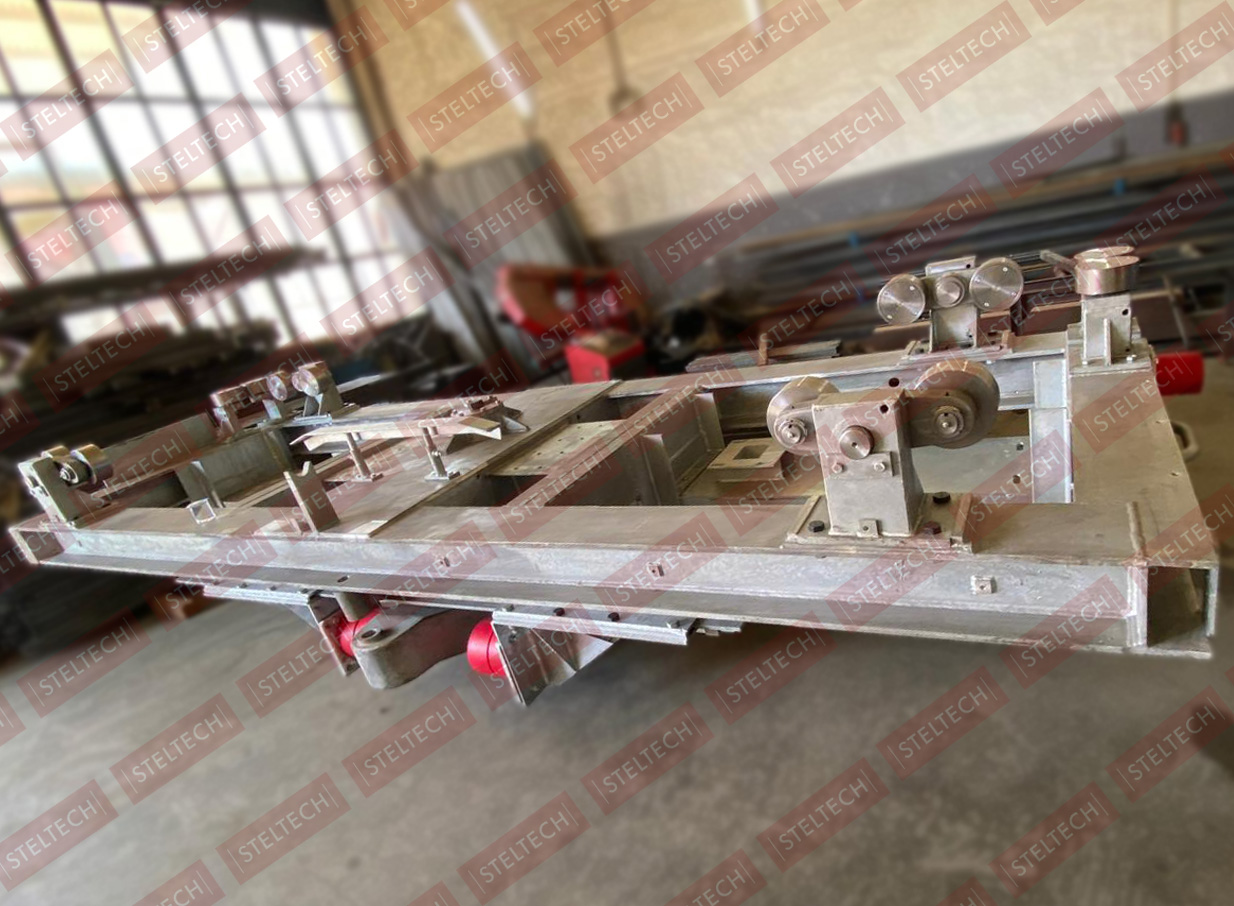

In the heart of every coke production facility lies a series of mechanical systems that ensure efficiency, safety, and continuity. One such critical component is the coal discharge plough, responsible for diverting, guiding, and discharging coal from conveyor systems during the coking process. This specialized equipment, manufactured with high precision by Steltech, plays a vital role in keeping coke plant operations smooth and uninterrupted.

When designing crane structures — especially in mining, excavation, or industrial settings — it’s not enough to ensure the beam won’t break. You also need to ensure it won’t bend too much. That’s where deflection (sehim) comes into play. Controlled deflection is critical for precision, safety, and structural integrity during lifting operations.