In metal forming processes, bending and welding operations play a crucial role in determining the durability, aesthetics, and functionality of a product. Post-bending welding, in particular, helps maintain structural integrity and ensures the design’s functionality. Improper management of these processes can lead to cracks, deformities, and production errors.

In metal forming and sheet processing industries, the relationship between material thickness and bending radius is a cornerstone of production quality. Incorrectly calculated bending radii can lead to material cracking, deformation, or structural failure.

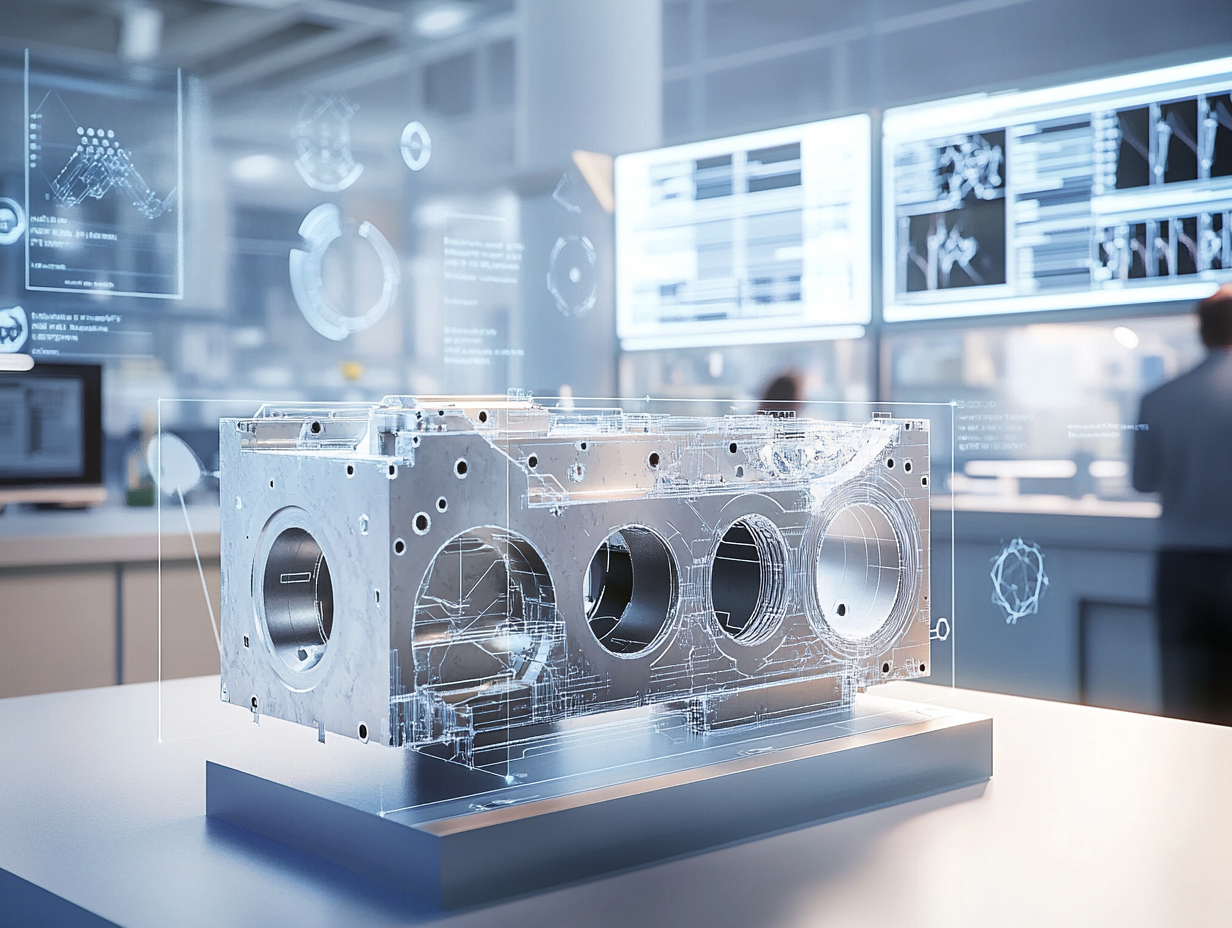

Materials used in casting significantly influence the durability, performance, and cost-effectiveness of the final product. Choosing the right material not only enhances quality but also improves production efficiency.

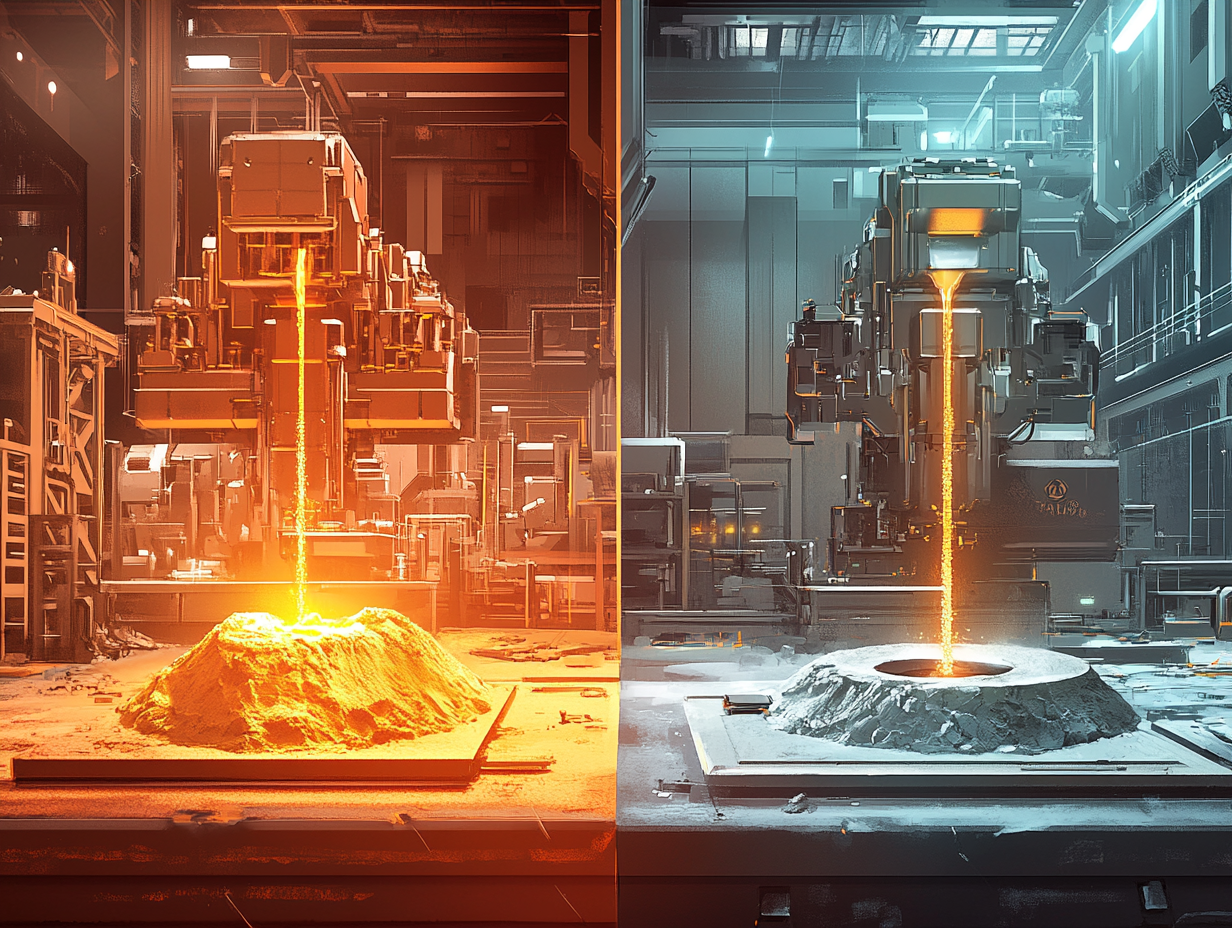

Casting processes are integral to modern manufacturing, offering tailored techniques for various applications. Selecting the right casting method is crucial for reducing costs, accelerating production, and achieving high-quality outcomes.

n industrial manufacturing, every millimeter counts. Particularly in casting processes, tolerances and shrinkage calculations play a pivotal role in determining the quality and functionality of the final product. These technical details not only optimize production costs but also ensure a flawless product that meets customer expectations.