In steel fabrication, one millimeter can be the difference between a perfect fit and a critical failure.At Steltech Makina, precision…

Strength You Can Measure In steel manufacturing, quality isn’t assumed — it’s proven.Every beam, sheet, and rebar that leaves a…

FMEA (Failure Modes and Effects Analysis) is a cornerstone of risk management, analyzing potential failure modes and their effects. However, like any powerful tool, it comes with both advantages and limitations.

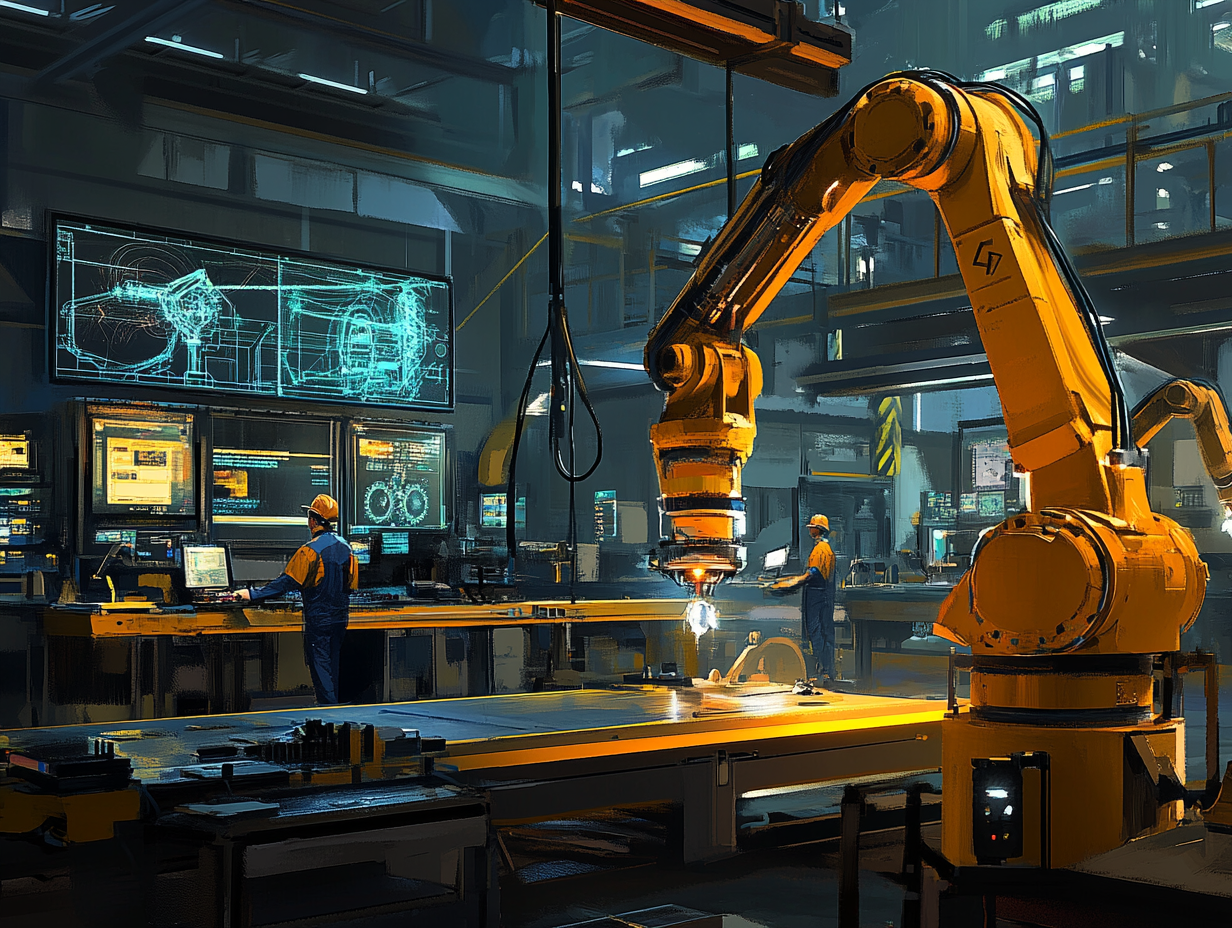

In modern manufacturing, well-prepared and standardized documentation plays a critical role in improving efficiency and minimizing errors. Manufacturing documents contain detailed technical drawings and standardized information used throughout the production process.

Risk management is one of the most critical elements in modern industrial processes. Fault Tree Analysis (FTA) is an effective method to identify the root causes of potential failures and their impacts on complex systems. This analysis enables proactive problem-solving and strategic risk mitigation.

Bending is a crucial step in metal forming, but post-bending welding plays an equally vital role in enhancing the durability and functionality of the final product. Proper welding applications ensure the structural integrity of materials while meeting safety and quality standards.

The relationship between material thickness and bending radius is essential for achieving quality and durable production in metalworking. Accurate calculations minimize the risk of cracking while ensuring precision in dimensions.

In construction projects, properly prepared documents are essential for ensuring success. Construction documents serve as the foundation for guiding the project team from the design phase to production. These documents maintain standards and improve communication across all stages of the project.

In casting production, achieving high-quality results goes beyond design and manufacturing. Testing and inspection processes are essential for ensuring the durability, performance, and compliance of cast parts with international standards. These processes help identify flaws early and enhance the final product.

In casting production, achieving a high-quality final product is not solely dependent on proper design and manufacturing processes. Testing and inspection are crucial for ensuring the performance and durability of cast parts. These processes detect production flaws and enhance product quality.

At Steltech, our commitment to quality and safety is unparalleled. In the world of engineering and construction, ensuring that materials are robust and fit for purpose is paramount. One of the key methods to assure material quality and structural integrity is through Nondestructive Testing (NDT). Today, we’re delving deep into one of the most fundamental NDT methods: Visual Inspection.