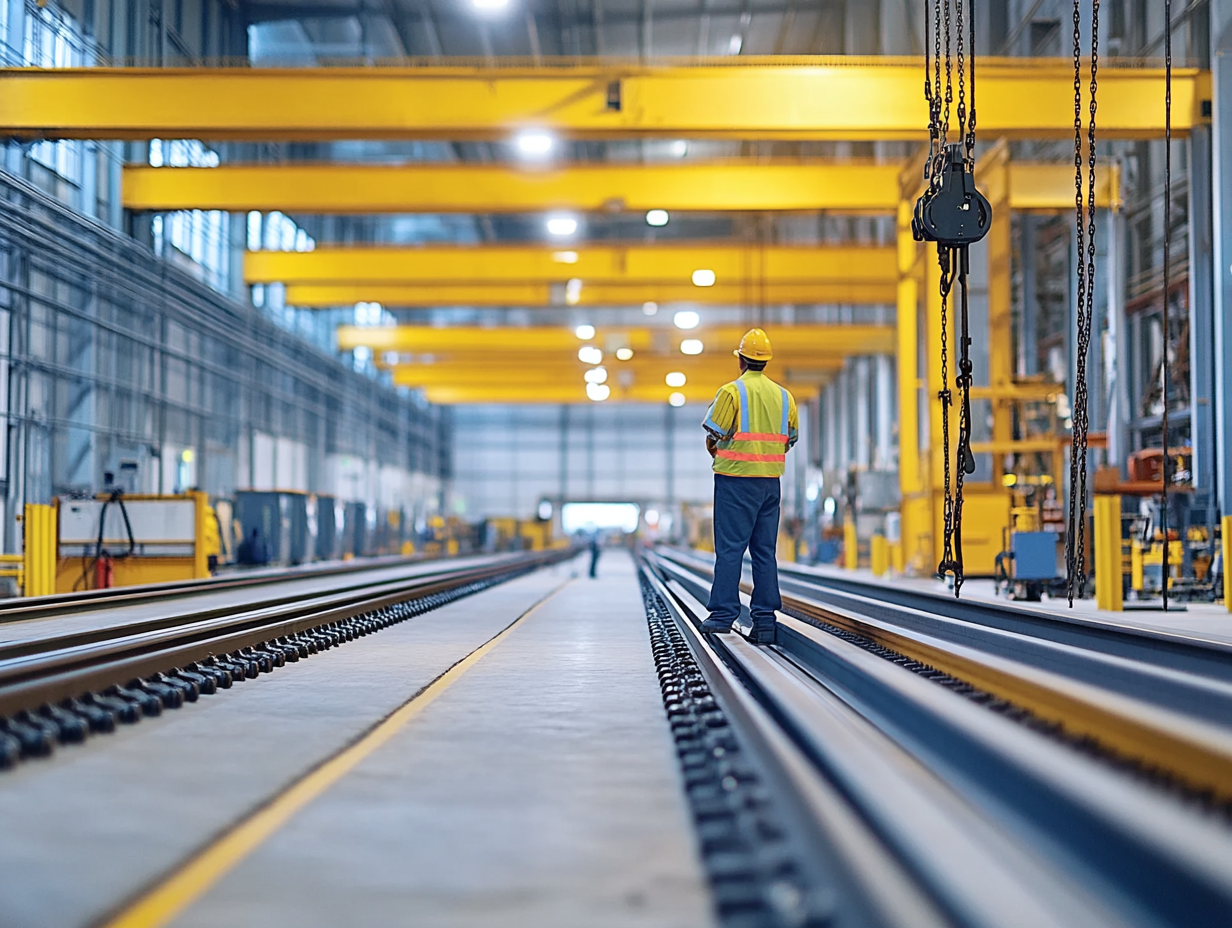

Proper installation of crane track rails is essential for ensuring alignment, structural integrity, and long-term durability. Poorly installed rails can lead to misalignment, excessive wear, and increased maintenance costs. This blog explores the best installation techniques, welding methods, and industry standards to follow for optimal crane track performance.

Flat bar crane rails, also known as laminated rails, are a widely used alternative to traditional crane rail profiles. These rails are particularly favored in light to medium-duty applications, offering flexibility and cost-effectiveness. However, they also come with specific limitations that must be considered when designing crane track systems. This blog explores the pros and cons of flat bar crane rails and their ideal applications.

Proper crane rail installation and bedding systems are essential for ensuring stability, durability, and reduced maintenance costs. Incorrect installation or improper bedding can lead to wear, deformation, and misalignment. This blog explores crane rail installation techniques, bedding systems, and key considerations for optimal performance.

Crane tracks must handle not only vertical loads but also lateral forces and torsion (twisting effects). Insufficient torsional resistance or uncontrolled lateral forces can cause rail deformations, crane instability, and serious operational issues. This blog explores how torsion is managed in crane tracks and the methods used to control lateral forces for optimal stability.

For crane tracks to operate safely and efficiently, they must meet specific tolerance standards. Misaligned rails can cause excessive wear on crane wheels, rail bending, and system failures.

The safety and efficiency of crane tracks depend on the accuracy of the structural construction. The quality of steel structures, connection details, and design tolerances ensure long-lasting and trouble-free operation.