Steel is the silent strength behind our modern world. From the fork you use at breakfast to the bridges that…

Bringing a steel furnace to life is as fascinating as it is demanding. Unlike flipping a switch, reaching full production…

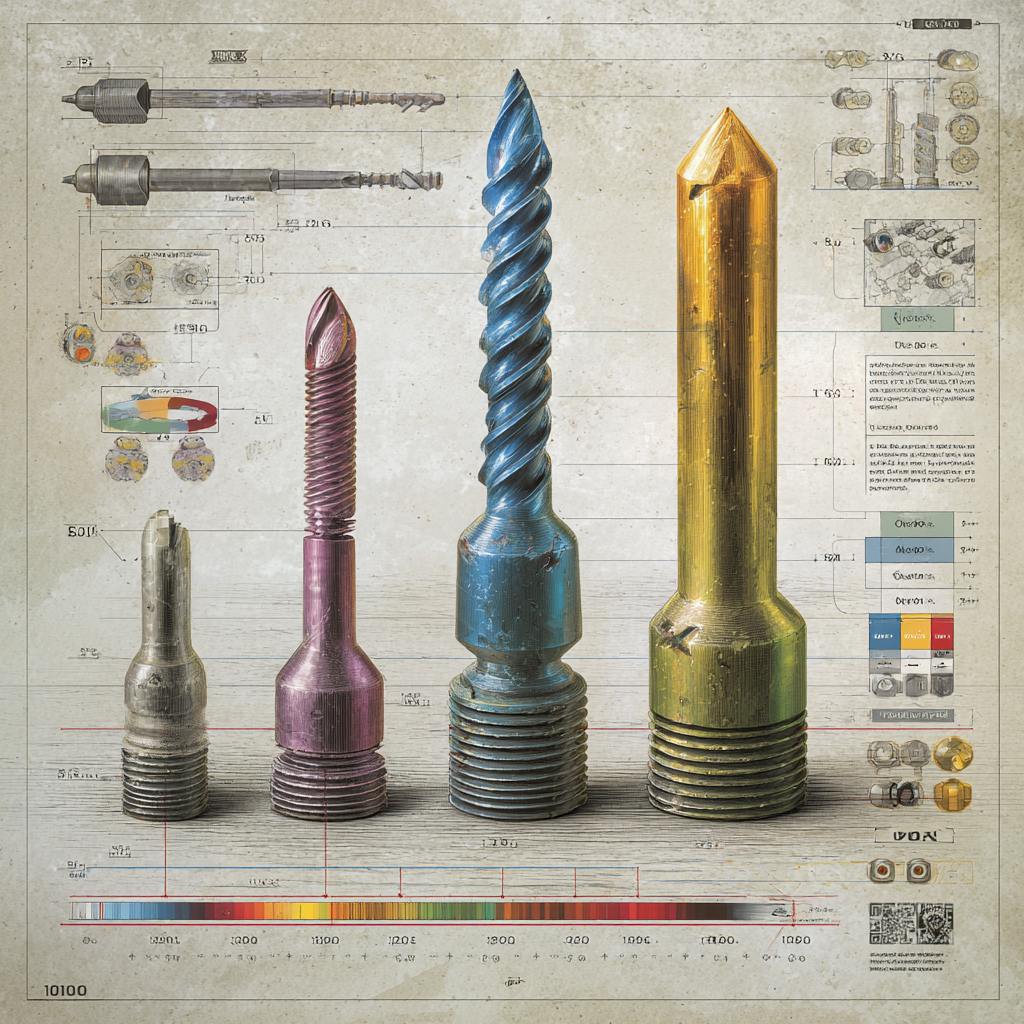

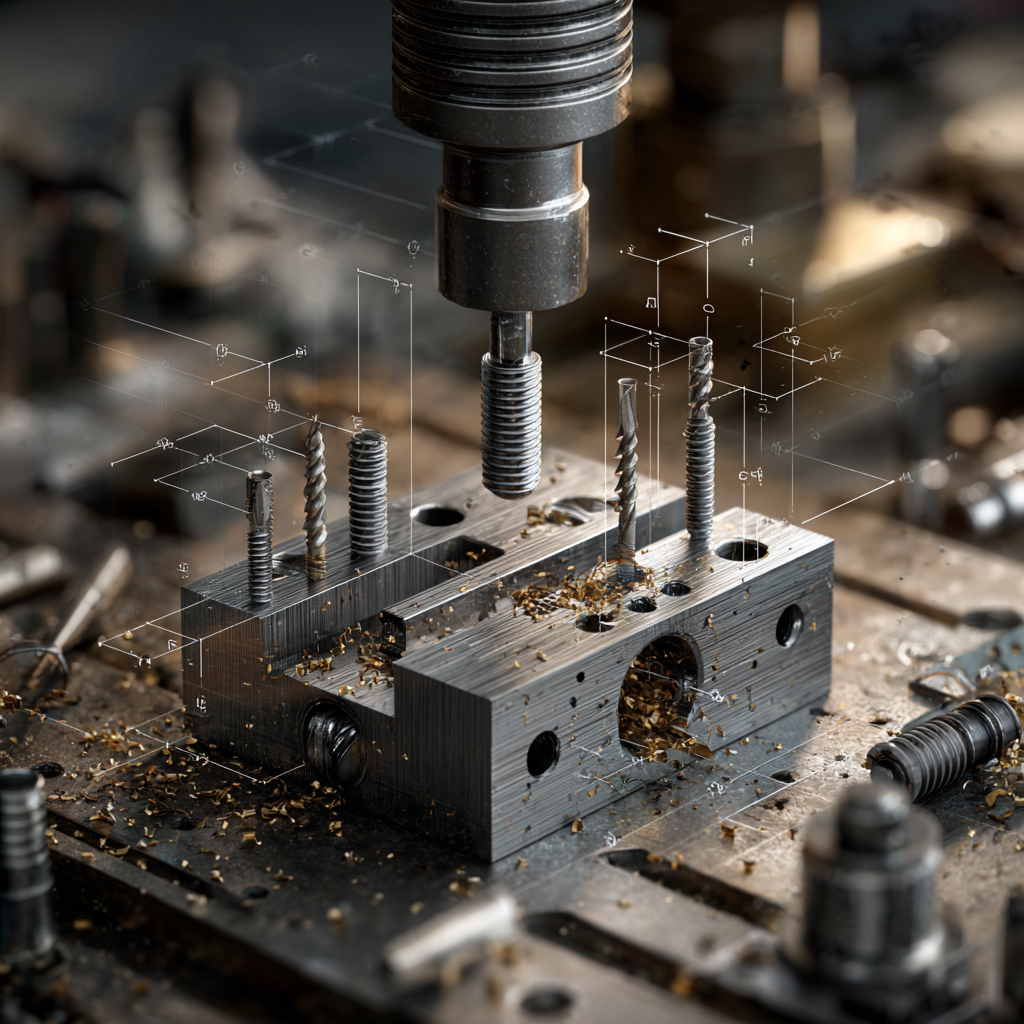

While standard drills and countersinks handle most machining tasks, specialized hole tools take precision and efficiency to the next level….

Taps and dies are the unsung heroes of engineering. They cut the precise threads that make bolts, screws, and nuts interchangeable worldwide — keeping mining machines, cars, and factories running smoothly.

Drills may create holes, but for true precision and durability, countersinks and center drills take the stage. These tools refine, guide, and prepare holes so that fasteners fit perfectly and machining remains accurate.

If dies create the external threads on bolts and rods, then taps are their natural counterpart cutting the internal threads…

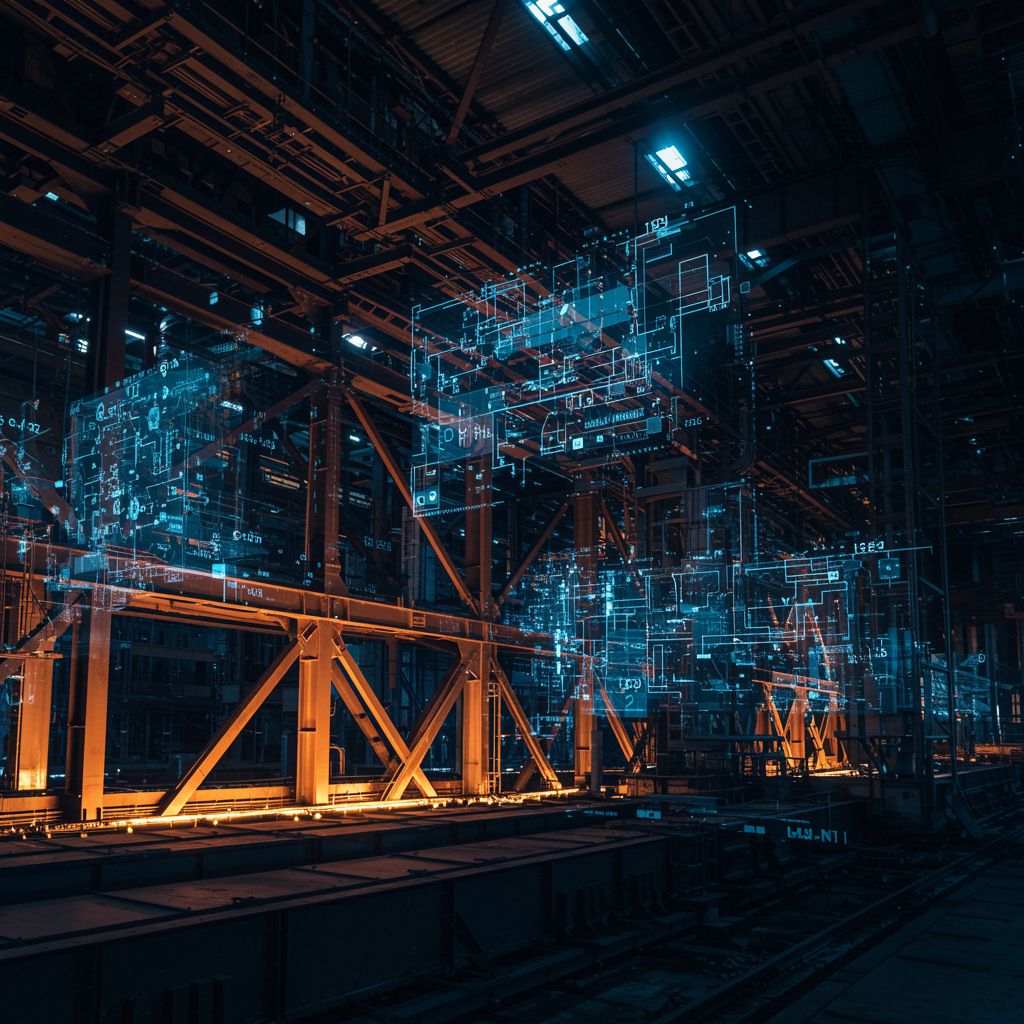

When designing steel crane structures especially those operating outdoors in mining, ports, and construction sites wind stability is a critical engineering concern. Even structures that are strong under static loads can fail due to lateral instability when subjected to wind, gusts, or pressure surges.

Behind every safe and reliable crane structure lies a deep layer of engineering logic — and at the heart of this logic are load group coefficients and hoisting load coefficients. These factors help engineers account for real-world operational conditions when calculating stresses, material fatigue, and safety margins.

When it comes to lifting heavy loads in mining, manufacturing, and port operations, equipment failure is not an option. That’s why industry professionals rely on rigorous standards like FEM (Fédération Européenne de la Manutention) to guide the design, classification, and load analysis of cranes.

In structural engineering, especially for cranes used in mining, knowing how a structure reacts to forces is the foundation of safe and efficient design. Two primary forms of load analysis are static and dynamic strength calculations — and they differ not just in theory, but in real-world performance, safety margins, and material behavior.

Understanding this distinction is critical when designing cranes, hoists, and material handling systems that operate in environments like open-pit mines, quarries, and coke plants, where loads vary constantly.

Selecting the correct crane for a mining or industrial project isn’t just about lifting capacity — it’s about matching the machine to the expected usage intensity. This is where the concepts of load groups (B classes) and duty classes (H classes) come into play. These classifications help engineers and decision-makers choose cranes that won’t just work — they’ll last.

In the mining and heavy machinery industries, safety isn’t optional — it’s engineered into every bolt, beam, and weld. One of the most critical concepts in structural crane design is the use of safety factors. These mathematical buffers ensure that structures withstand not only known loads but also unexpected forces, imperfections, and usage variations. In essence, safety factors protect lives and investments.

Understanding crane load conditions is essential in designing safe and reliable lifting systems — especially in demanding fields like mining, construction, and logistics. These classifications (H, HZ, and HS) define the environmental and operational stresses a crane is expected to handle. Selecting the correct condition is key to ensuring structural integrity and operational longevity.