Bringing a steel furnace to life is as fascinating as it is demanding. Unlike flipping a switch, reaching full production…

When it comes to shaping and machining steel, precision is everything. A drill bit labeled “5mm” must always measure 5mm, no matter who manufactured it. This is where DIN standards (Deutsches Institut für Normung) come into play. Established in Germany, DIN ensures that tools and components are consistent, reliable, and interchangeable.

When designing steel crane structures especially those operating outdoors in mining, ports, and construction sites wind stability is a critical engineering concern. Even structures that are strong under static loads can fail due to lateral instability when subjected to wind, gusts, or pressure surges.

Behind every safe and reliable crane structure lies a deep layer of engineering logic — and at the heart of this logic are load group coefficients and hoisting load coefficients. These factors help engineers account for real-world operational conditions when calculating stresses, material fatigue, and safety margins.

When it comes to lifting heavy loads in mining, manufacturing, and port operations, equipment failure is not an option. That’s why industry professionals rely on rigorous standards like FEM (Fédération Européenne de la Manutention) to guide the design, classification, and load analysis of cranes.

In structural engineering, especially for cranes used in mining, knowing how a structure reacts to forces is the foundation of safe and efficient design. Two primary forms of load analysis are static and dynamic strength calculations — and they differ not just in theory, but in real-world performance, safety margins, and material behavior.

Understanding this distinction is critical when designing cranes, hoists, and material handling systems that operate in environments like open-pit mines, quarries, and coke plants, where loads vary constantly.

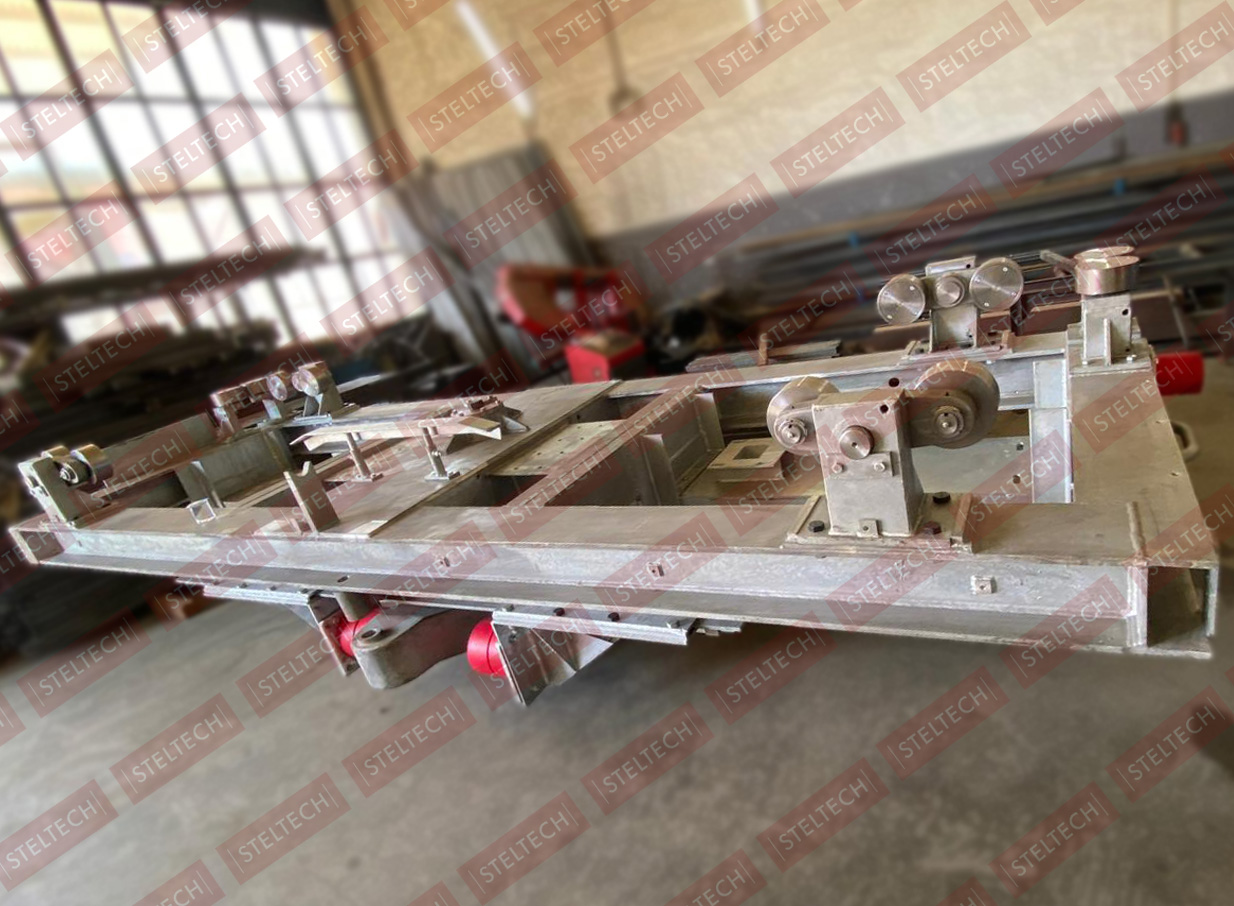

In the heart of every coke production facility lies a series of mechanical systems that ensure efficiency, safety, and continuity. One such critical component is the coal discharge plough, responsible for diverting, guiding, and discharging coal from conveyor systems during the coking process. This specialized equipment, manufactured with high precision by Steltech, plays a vital role in keeping coke plant operations smooth and uninterrupted.

When designing crane structures — especially in mining, excavation, or industrial settings — it’s not enough to ensure the beam won’t break. You also need to ensure it won’t bend too much. That’s where deflection (sehim) comes into play. Controlled deflection is critical for precision, safety, and structural integrity during lifting operations.

Understanding crane load conditions is essential in designing safe and reliable lifting systems — especially in demanding fields like mining, construction, and logistics. These classifications (H, HZ, and HS) define the environmental and operational stresses a crane is expected to handle. Selecting the correct condition is key to ensuring structural integrity and operational longevity.

Stacker reclaimer is one of the heavy machines used in the bulk material handling industry, especially in ports, terminals, steel plants, and mines, providing a functional solution for both material stacking and reclaiming processes.