In modern steelmaking, precision and sustainability go hand in hand. At Steltech, we focus on engineering solutions that boost efficiency, cut costs, and deliver higher-quality steel. One of the most powerful innovations in this space is the Carbon Multi-Point Injection System for Electric Arc Furnaces (EAFs).

Steel, an essential material in modern industries, is an alloy of iron and carbon. Steel production involves removing various elements from raw iron to create an alloy with desired properties. This process begins with chemical reactions such as oxidation and reduction, followed by several stages depending on the production method. The primary goal of steel production is to reduce carbon and other elements to desired levels, purify the alloy, and produce high-quality steel.

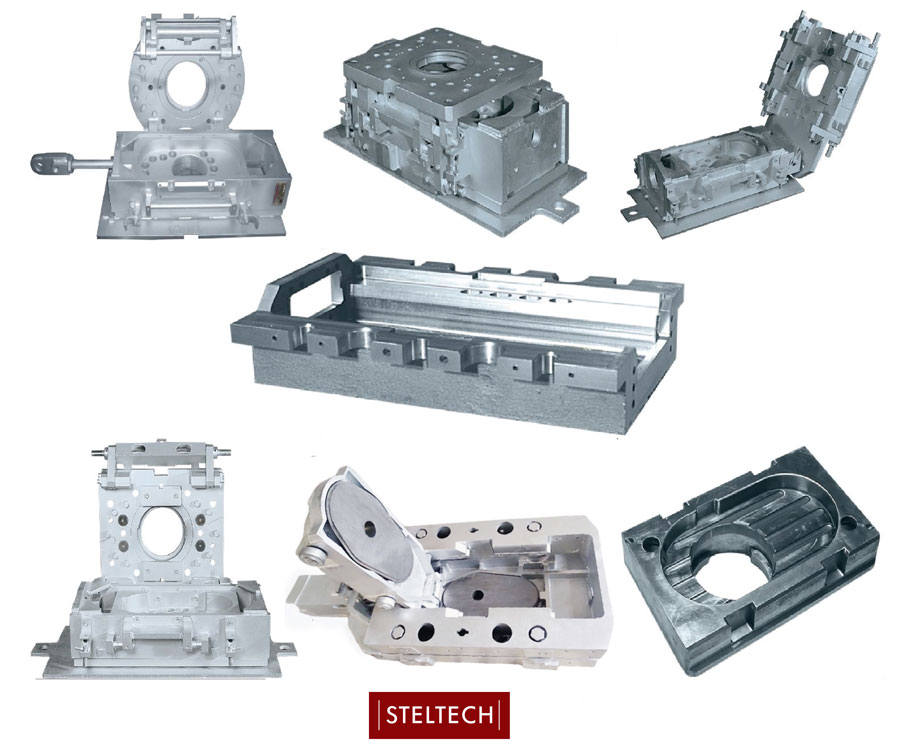

Steel mill machinery is one of the most important equipment in steel production. These machines are used in many different stages of steel production, from processing raw materials to shaping steel sheets, plates, and bars.

Tundish mechanisms are an essential part of the steelmaking process. They help regulate the flow of molten steel from the ladle to the mold or another vessel. There are different types of tundish mechanisms, such as the plunger mechanism, level controller mechanism, flow control valves, and launder system.

- Blog, Machinery

-

EfficiencyImprovement, EngineeringMaintenance, FlowControl, HighQualitySteel, IndustrialEngineering, MoltenSteel, ReducingDefects, RegularMaintenance, SkilledTechnicians, steelindustry, SteelMakingProcess, SteelManufacturing, SteelOutput, SteelProduction, SteelProductQuality, SteelValue, SurfaceDefectsPrevention, TundishInspection, TundishMechanisms