Cantilever beams are widely used in mining and heavy industrial equipment, particularly where support is only possible on one end….

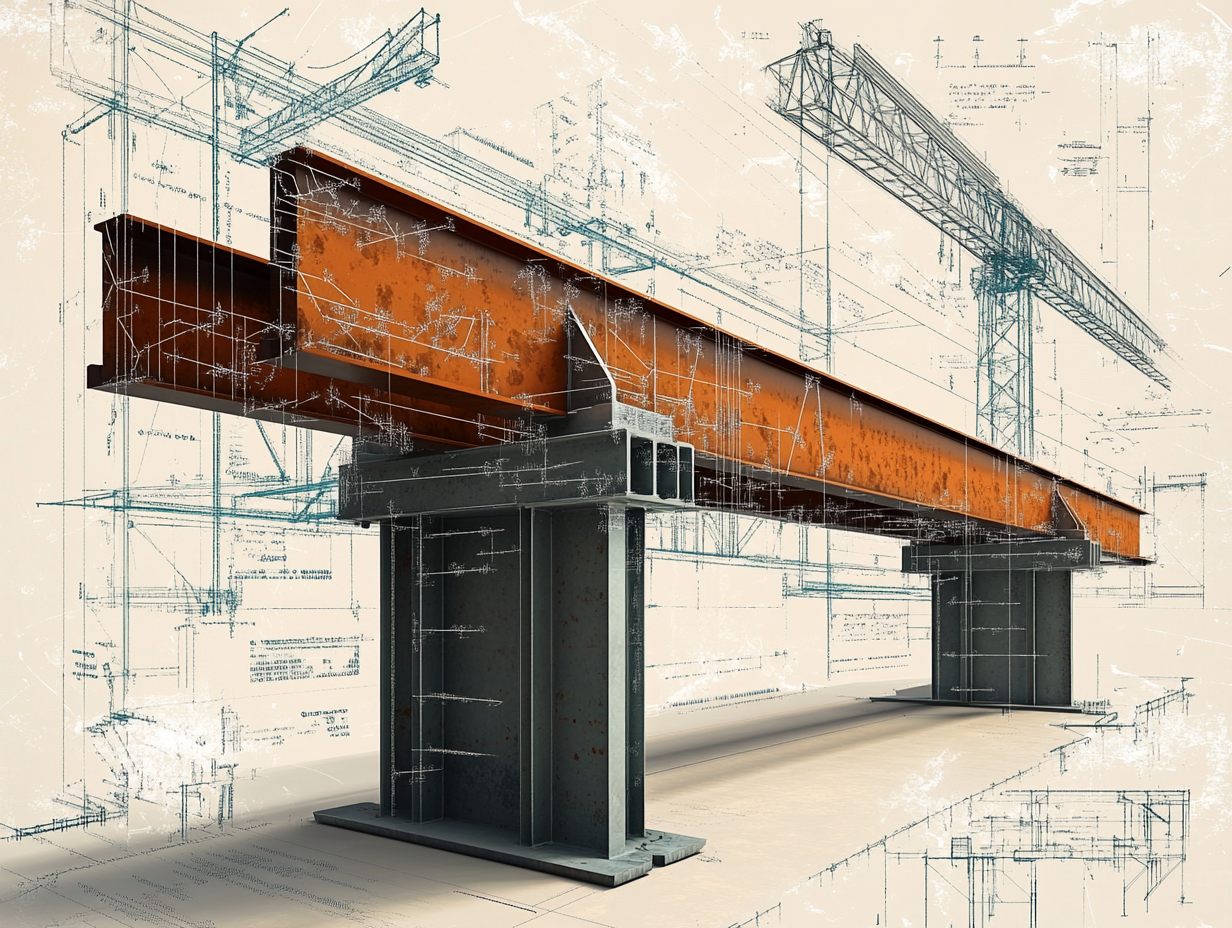

In mining infrastructure and heavy machinery, beams are everywhere from conveyor support frames to equipment platforms and structural walkways. One of the most common configurations is the simply supported beam, where the beam is supported at both ends but free to bend under load.

When designing steel crane structures especially those operating outdoors in mining, ports, and construction sites wind stability is a critical engineering concern. Even structures that are strong under static loads can fail due to lateral instability when subjected to wind, gusts, or pressure surges.

Behind every safe and reliable crane structure lies a deep layer of engineering logic — and at the heart of this logic are load group coefficients and hoisting load coefficients. These factors help engineers account for real-world operational conditions when calculating stresses, material fatigue, and safety margins.

Non-preloaded bolted connections are widely used in steel structures, particularly in applications where high-strength clamping forces are not required. These connections rely on bearing resistance and shear capacity, making them suitable for low to moderate load conditions. In this blog, we explore the mechanical behavior, strength calculations, and best practices for designing non-preloaded bolted connections.