In the world of heavy-duty industrial machinery, the performance of a machine depends heavily on the strength and engineering of…

Steel is the silent strength behind our modern world. From the fork you use at breakfast to the bridges that…

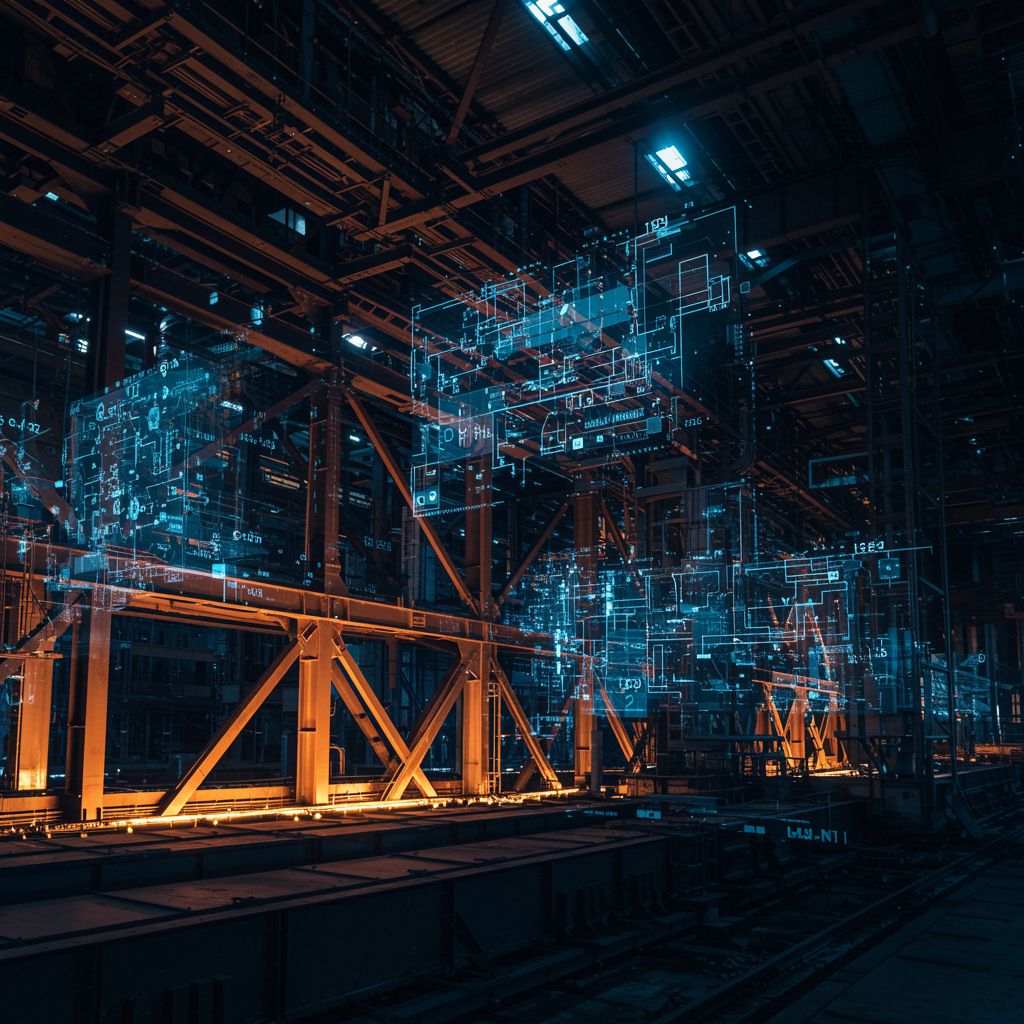

When designing crane structures — especially in mining, excavation, or industrial settings — it’s not enough to ensure the beam won’t break. You also need to ensure it won’t bend too much. That’s where deflection (sehim) comes into play. Controlled deflection is critical for precision, safety, and structural integrity during lifting operations.

In the mining and heavy machinery industries, safety isn’t optional — it’s engineered into every bolt, beam, and weld. One of the most critical concepts in structural crane design is the use of safety factors. These mathematical buffers ensure that structures withstand not only known loads but also unexpected forces, imperfections, and usage variations. In essence, safety factors protect lives and investments.

In crane design — especially in heavy industries like mining and infrastructure — selecting the right steel is crucial. Two of the most commonly used structural steels are St37-2 and St52-3. Each has unique mechanical properties that make it suitable for different applications, environments, and load conditions. Understanding their differences is essential for engineers, designers, and project managers aiming to build safe, durable, and cost-effective cranes.

Steel construction plays a fundamental role in ensuring the structural integrity, operational efficiency, and safety of cranes used in various industries, from mining to logistics. As one of the most critical engineering aspects of lifting systems, a solid grasp of steel construction principles can significantly influence design decisions and long-term performance.

Non-preloaded bolted connections are widely used in steel structures, particularly in applications where high-strength clamping forces are not required. These connections rely on bearing resistance and shear capacity, making them suitable for low to moderate load conditions. In this blog, we explore the mechanical behavior, strength calculations, and best practices for designing non-preloaded bolted connections.

Bolted connections are essential in steel construction, providing strength, flexibility, and ease of assembly. These connections allow for structural integrity while facilitating maintenance and modifications. In this blog, we explore the types, advantages, and applications of bolted connections in steel structures.

Crane tracks used in open yard environments face unique challenges, including weather exposure, temperature fluctuations, and increased lateral forces. Unlike indoor installations, these tracks must be engineered for durability, stability, and resistance to environmental conditions. This blog explores the key factors in designing crane rail systems for open yards and best practices for ensuring long-term performance.